Machine is designed to make shelf panels in batch automatically. This machine rollers can be adjusted to your drawing profile width and length. helf panel roll forming machine can be customized to your specification ideal for making different styles such as adjustable size, punching holes, embossing logo, making light or heavy duty panels and more…

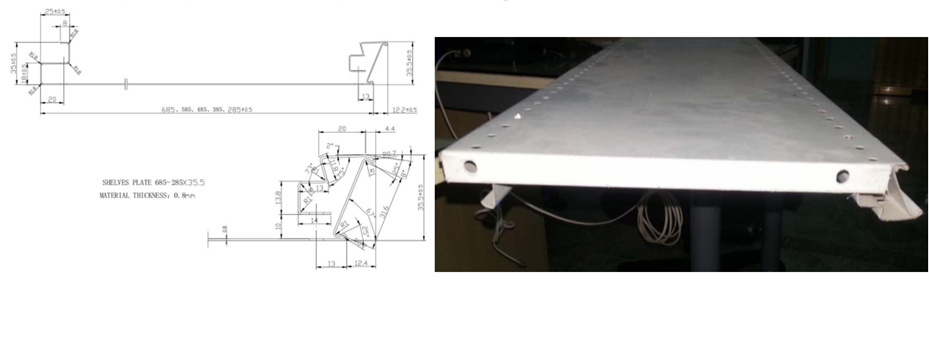

Sample picture for reinforcing shelf panel for heavy duty use

The below profile drawing sample picture shows there are 5 different sizes in width for the finish product:

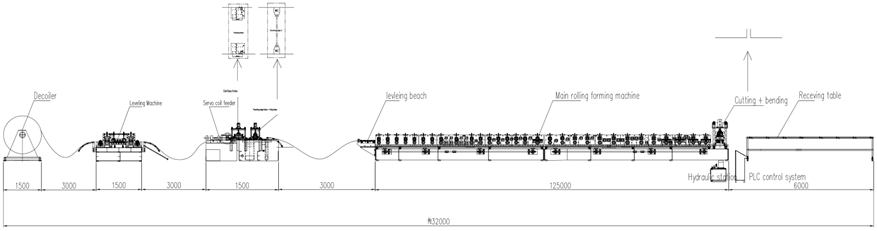

Machine Production Process

Decoiler -> Leveling -> Servo Coil Feeder -> Hydraulic Punching -> Leveling -> Rollers – > Cutting + Bending -> Collecting Table

Over the years, by addressing practical production challenges for our customers, we have absorbed the finest features of similar products both domestically and internationally, enhancing the design and performance of our Adjustable Width Linear Shelf Panel Roll Forming Machine. This machine is specifically engineered for flexibility, allowing it to adapt to various shelf panel sizes, making it ideal for the competitive market environment. With the help of cutting-edge technology and sophisticated equipment, we continue to build a strong foundation for success and long-term growth. Our clients span across North America, Africa, and Eastern Europe, all benefiting from our commitment to quality and innovation.

Key Features of the Adjustable Width Linear Shelf Panel Roll Forming Machine

Our machine allows for precise adjustments in panel width, providing flexibility to accommodate various shelving systems, such as those used in supermarkets, department stores, and warehouses. The roll forming stands can be moved along linear guides to fine-tune the gap between rollers, enabling the production of shelf panels in different sizes with minimal downtime.

Adjustable Width Linear Shelf Panel Roll Forming Machine

This roll forming machine comprises the following components:

Active uncoiler

High-precision punch feeder

High-speed punching press (including die)

Precision cold rolling forming machine with adjustable rollers

CNC shear for precise cutting

Receiving rack for finished products

Applications

Supermarket Shelving Systems

The machine is ideal for producing panels for supermarket shelving, which require different widths and specifications based on shelf design and usage.

Storage and Pallet Racking

Storage systems often need adjustable shelving solutions, and this machine can accommodate a wide range of shelving needs, including pallet racking systems.

Customizable Shelving

With its adjustable width feature, the machine is perfect for creating custom shelves tailored to the specific needs of clients in retail and warehouse industries.

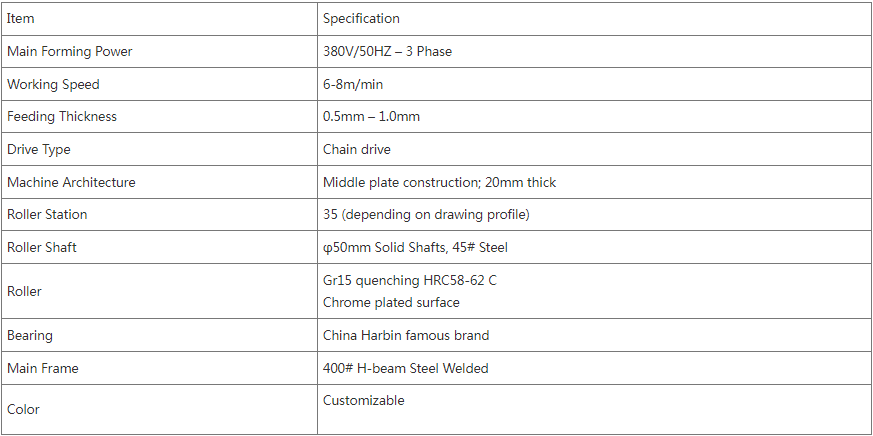

Technical Specifications:

Raw Material Thickness: 0.5-1 mm

Material: G350Mpa cold-rolled steel, hot-rolled steel, or galvanized steel

Input Material Width: Adjustable based on required shelf dimensions

Production Speed: 6-8 m/min for optimized output without compromising quality

Working Area: Approximately L15,000*W2,000 mm, accommodating efficient production

Main Components:

Hydraulic Decoiler: Ensures smooth and continuous feeding of raw material into the machine.

Servo Feeding Device: Offers high precision in material feeding, maintaining consistency.

Hydraulic Punch Machine with Dies: Allows for customization and accurate punching as per design requirements.

Adjustable Roll Forming Stands: Equipped with linear guides to enable easy adjustment of panel width.

Output Table: Receives the finished shelf panels.

Hydraulic Oil Pump: Powers the hydraulic system for decoiling and punching.

Electrical Control Cabinet: Centralized control for seamless operation of the entire production line.

Benefits:

Adaptability: Capable of producing different shelf panel sizes with quick and easy adjustments.

Efficiency: High production speed ensures timely output, meeting high demand.

Precision: Advanced servo feeding and CNC cutting systems guarantee accuracy in every panel.

Cost-Effective: Reduced waste and downtime through precise adjustments, maximizing material usage.

The Adjustable Width Linear Shelf Panel Roll Forming Machine is an all-in-one solution for manufacturing high-quality, customized shelf panels, making it indispensable in modern retail and storage industries.