This machine is designed for the automated, high-volume production of shelf panels. Its rollers are adjustable to accommodate your specific width and length requirements based on your design. The shelf panel roll forming machine can be fully customized to meet your specifications, making it ideal for creating various panel styles, including adjustable sizes, punched holes, embossed logos, and options for both light-duty and heavy-duty panels.

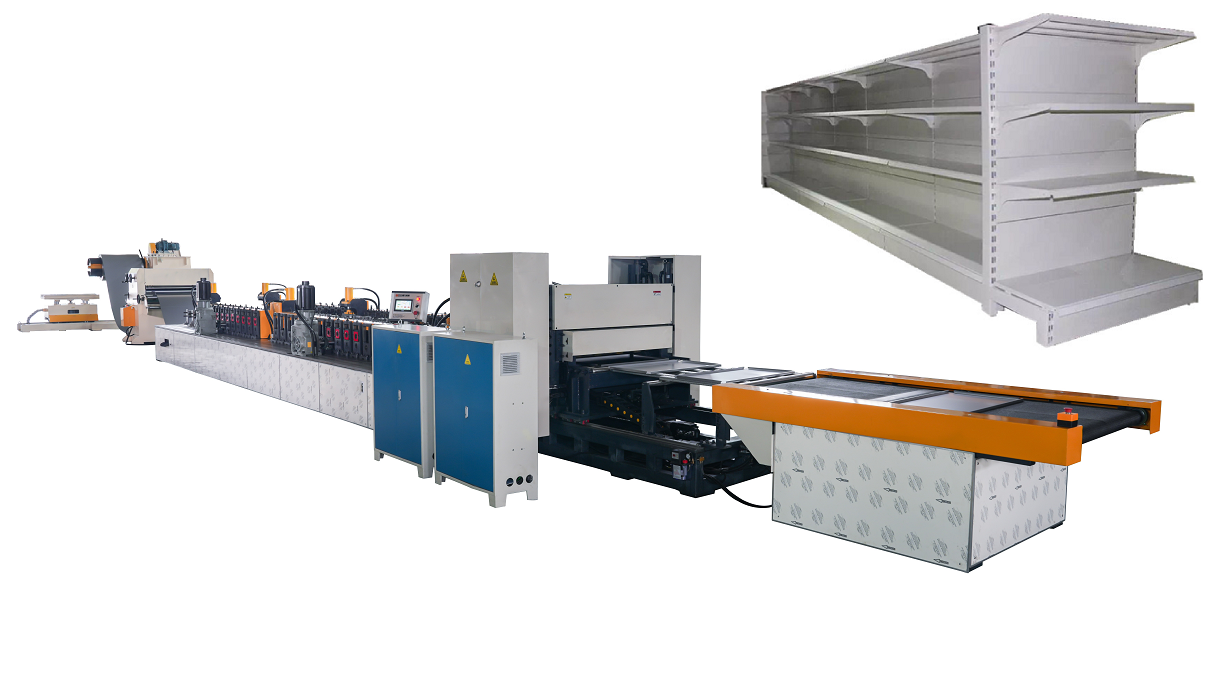

Sample picture for reinforcing shelf panel for heavy duty use

Supermarket Storage Rack Panel Roll Forming Machine

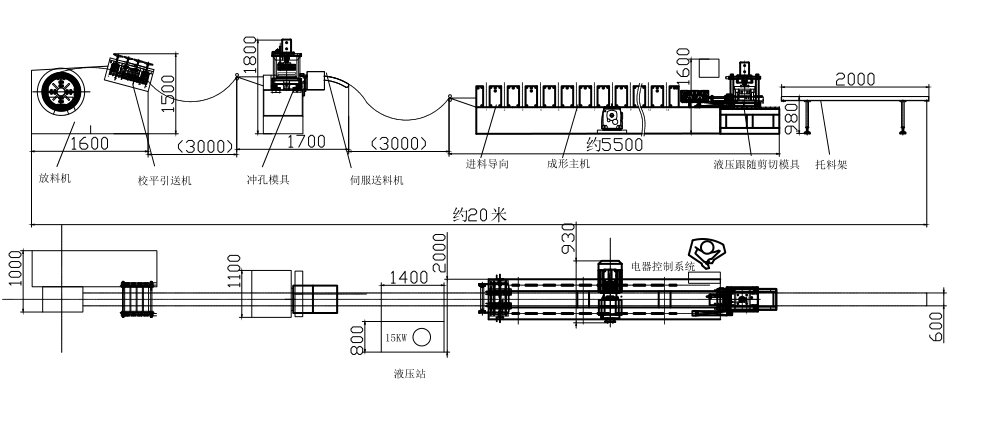

Shelf Panel Making Machine Production Process

Unwinder: used to support and unwind the metal coil so that the coil enters the forming process smoothly.

Feed guide device: used to accurately guide the metal sheet into the machine to ensure that it remains in a stable position during the forming process.

Roll forming main machine: This is the core forming part, which consists of multiple sets of rollers. Each set of rollers gradually presses the metal sheet according to the designed shape to form the specific contour and structure of the shelf panel.

Cutting system: usually a hydraulic or pneumatic cutting device, which automatically cuts the finished product according to the preset length to ensure the consistent size of the panel.

Automatic stacking system: The formed shelf panel is transported to the stacking device through the conveying system for subsequent packaging and transportation.

Control system: Most forming machines are equipped with PLC (programmable logic controller) control. The panel length, production speed and other parameters can be adjusted through the operation panel to achieve automatic control.

Design of the Shelves Panel Automatic Production Line

This shelves panel automatic production line is designed for high-efficiency production of various shelf panel specifications, integrating multiple processes into a single streamlined system. The line incorporates advanced numerical control (NC) to handle punching, shearing, cold roll forming, and folding processes, effectively replacing the need for separate CNC punching, bending, and shearing machines. This integration significantly reduces labor requirements, enhances productivity, and minimizes the time and cost associated with traditional manufacturing methods.

ZTRFM Shelving Equipment Features

1.The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient.

2.The forming frame is welded using high strength channel steel. High strength and long service life.

3.The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

4.The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C.

5.The transmission structure is gearbox transmission or chain transmission.

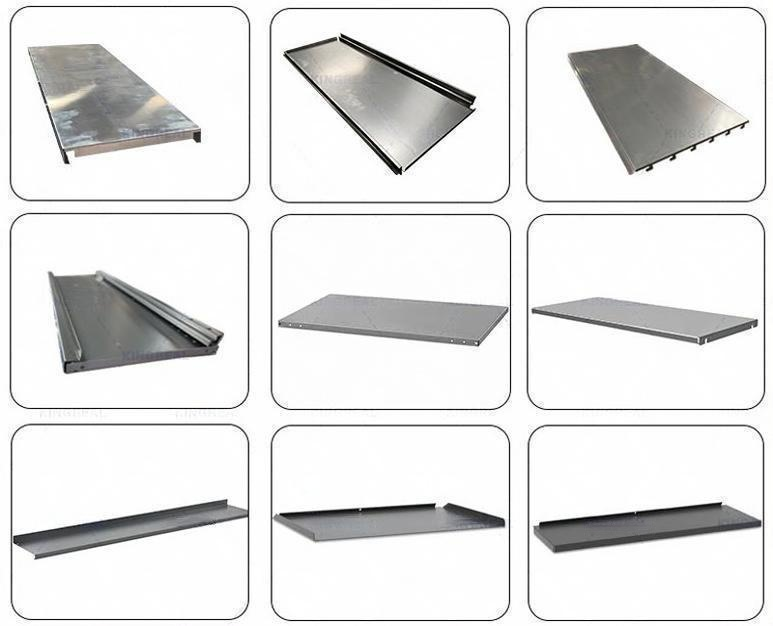

Final Product Display

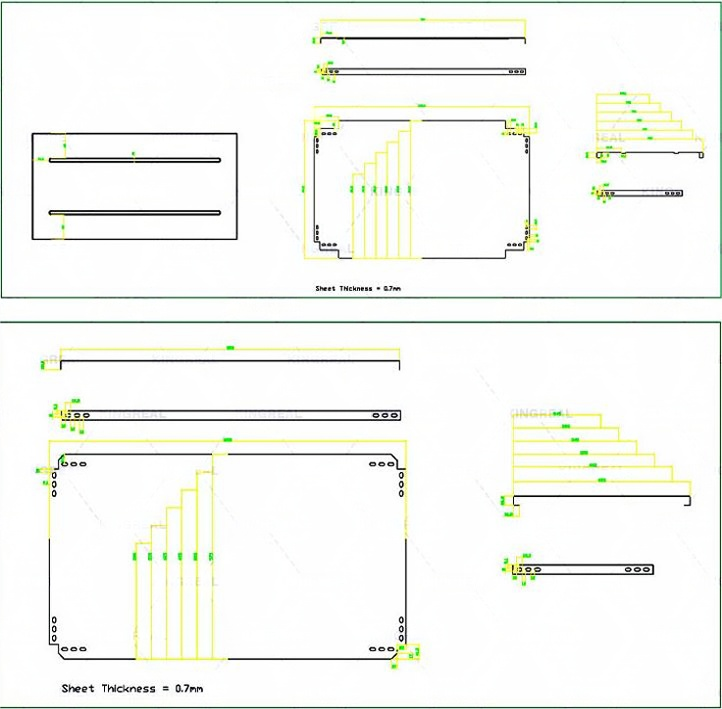

Reference drawings of different metal shelf

Mainly Include

– Shelf post roll forming equipment

– Shelf rack panel roll forming machine

– Shelf beam (Box beam) cold roll forming machine

– Shelf step beam (P beam) automatic roll forming production line

– Shelf reinforcement rib roll forming equipment

– Shelf label slot roll forming production equipment

– Shelf universal Angle steel roll forming production equipment

– Shelf bullet beam cold bending forming machine