What Is a Batten Roll Forming Machine?

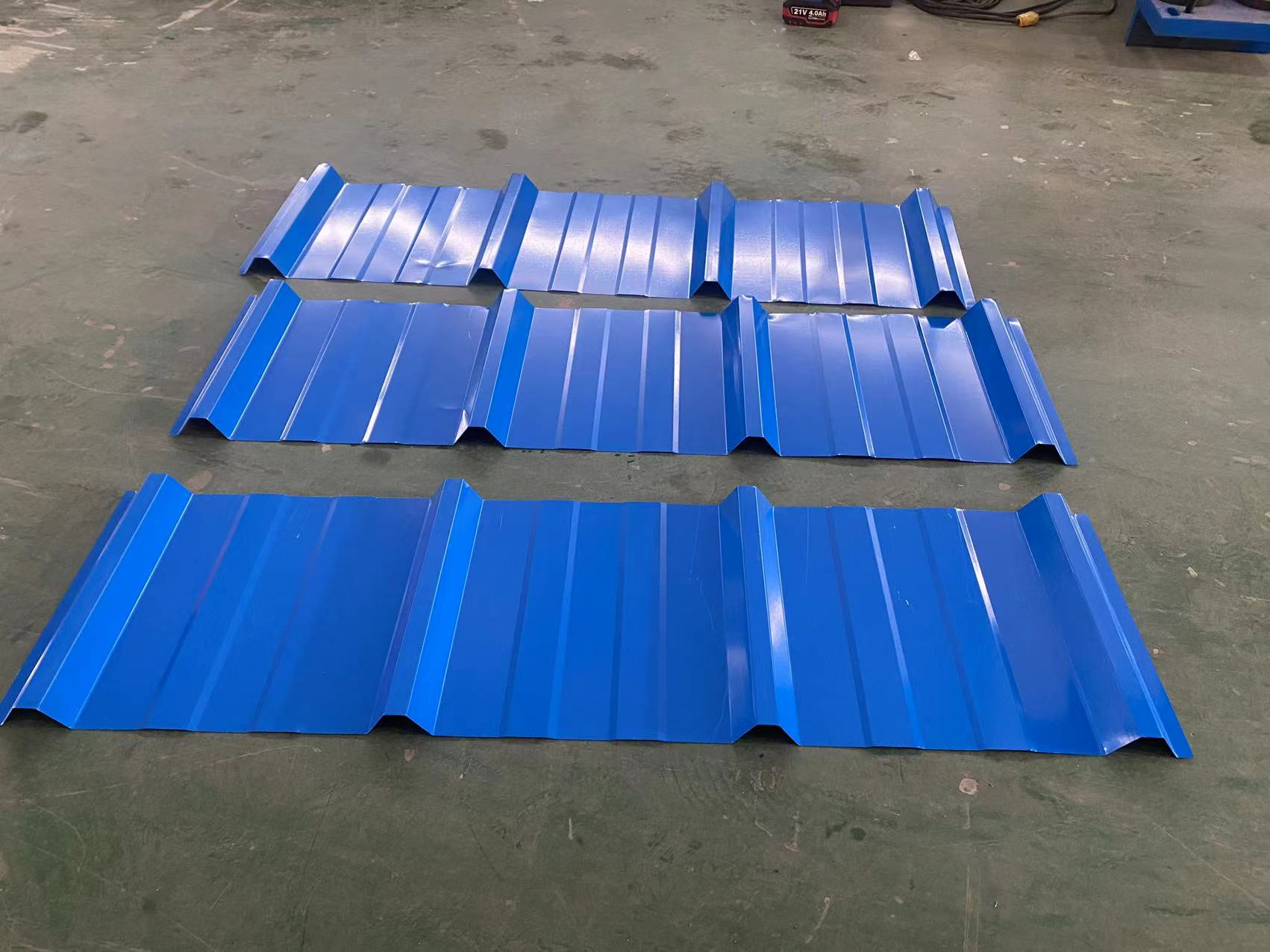

A batten roll forming machine is specialized equipment used to manufacture metal battens, commonly used in roofing and cladding systems. These machines shape metal sheets into precise batten profiles through a continuous bending process. They ensure uniformity, high production speed, and cost efficiency, making them a crucial investment for metal fabrication businesses.

Key Features of a Batten Roll Forming Machine

High Precision Forming – These machines are designed to produce battens with exact dimensions and consistency, ensuring seamless installation.

Automated Operation – Modern batten roll formers are equipped with PLC control systems that allow for automated feeding, cutting, and stacking.

Versatile Material Compatibility – Can process various metals such as galvanized steel, aluminum, and stainless steel.

Adjustable Design Options – Some machines offer customizable roller configurations to produce battens of different sizes and profiles.

Benefits of Using a Batten Roll Forming Machine

Increased Production Efficiency – Roll forming allows for continuous, high-speed production, reducing manual labor and improving output.

Cost-Effective Manufacturing – Automated processes minimize material wastage and operational costs.

Consistent Product Quality – Advanced roller dies ensure uniform thickness and precise shaping, eliminating inconsistencies.

Reduced Material Waste – Unlike stamping or pressing, roll forming optimizes material usage with minimal scrap.

How to Choose the Right Batten Roll Forming Machine

Production Capacity – Consider the required output volume and machine speed to match your business needs.

Customization Options – Look for machines that allow profile adjustments for different project requirements.

Durability and Maintenance – Opt for machines built with high-quality components to ensure longevity and minimal downtime.

Control System – A user-friendly PLC control system enhances automation and reduces the need for manual intervention.

Where to Buy a Batten Roll Forming Machine?

Batten roll forming machines can be purchased from specialized manufacturers, industrial equipment suppliers, and online marketplaces. When selecting a supplier, consider:

Reputation and Reviews – Choose a supplier with positive customer feedback and a history of reliable service.

After-Sales Support – Ensure the manufacturer provides technical support, training, and spare parts availability.

Customization Services – Some suppliers offer tailored solutions to match specific production needs.

Conclusion

Investing in a batten roll forming machine can significantly enhance production efficiency and product quality for businesses in the roofing and construction industries. By selecting the right machine with advanced features and reliable after-sales support, manufacturers can maximize their operational output while reducing costs. Whether you’re a small business or a large-scale production facility, a well-chosen batten roll former is a valuable asset for long-term growth.