The Box Beam Roll Forming Machine is a highly specialized piece of equipment engineered for the production of box-shaped structural beams used in a variety of heavy-duty applications. Box beams are integral components in the construction of shelving systems, building frameworks, bridges, and other structures where high strength and durability are required. This machine is designed for efficiency, precision, and customization, enabling manufacturers to produce box beams that meet diverse industry standards.

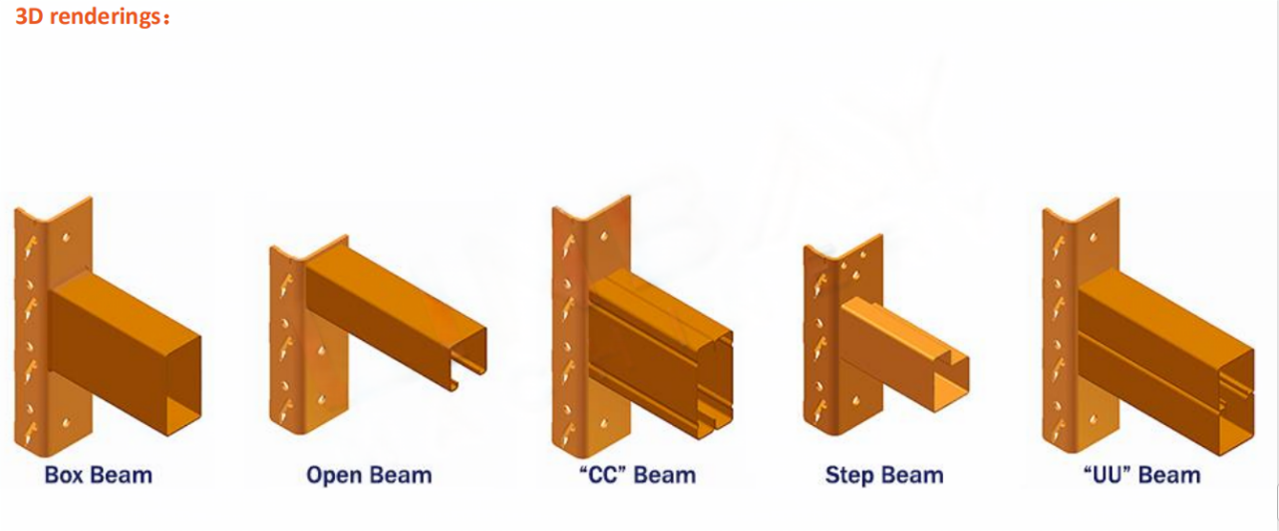

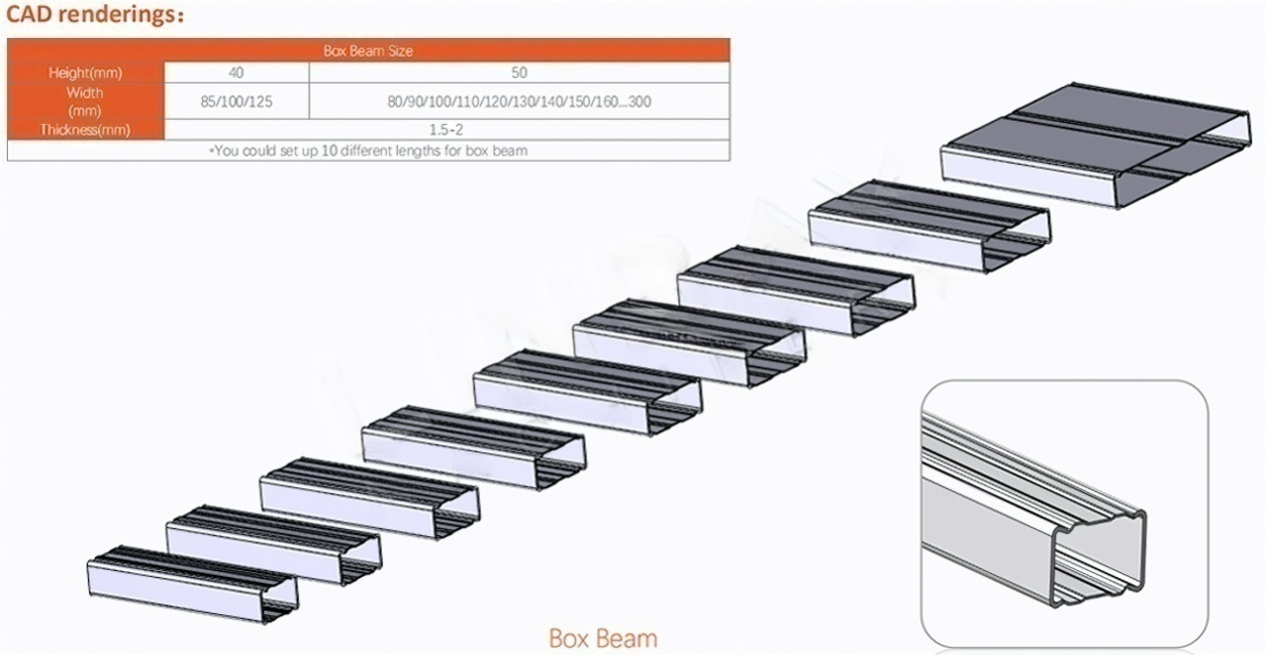

Pallet upright rack roll forming machine is widely used in producing upright frame, box beam and step beam. Our intelligent roll forming machine could make wide range of sizes using cantilever type structure, and automatically change by motors from one size to the other not only at width but also at height. The one and only step is to put your required data into our touch screen and wait for few seconds. Machinable thickness is from 1.5-3mm with raw material Cold-rolled Steel, Galvanized Coil, PPGI, Carbon steel, Stainless Steel and Aluminum. Our produced profile meet ISO, CE , FEM standards, and our machine is applied to Warehouse ,supermarket ,industry or home.

Application

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of ZTRFM will ensure you obtain perfectly functional profiles.

Industrial Storage Systems: Box beams are widely used in shelving and racking systems, providing superior strength and stability for heavy-duty applications like pallet racks and warehouse shelving.

Construction and Infrastructure: In building structures, box beams are used in frameworks and supporting columns due to their high load-bearing capacity.

Logistics and Transport: Box beams can be used in the manufacturing of heavy-duty trailers and containers.

Bridges and Large-Scale Projects: They are critical components in bridge construction and other civil engineering projects requiring strong, durable materials.

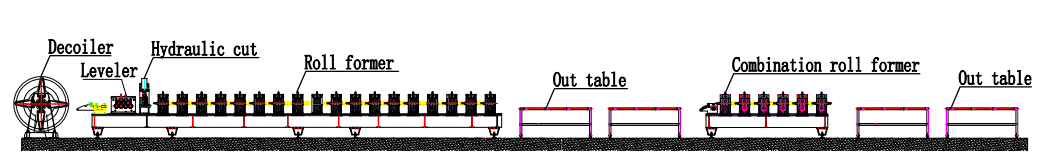

Machine Production Process

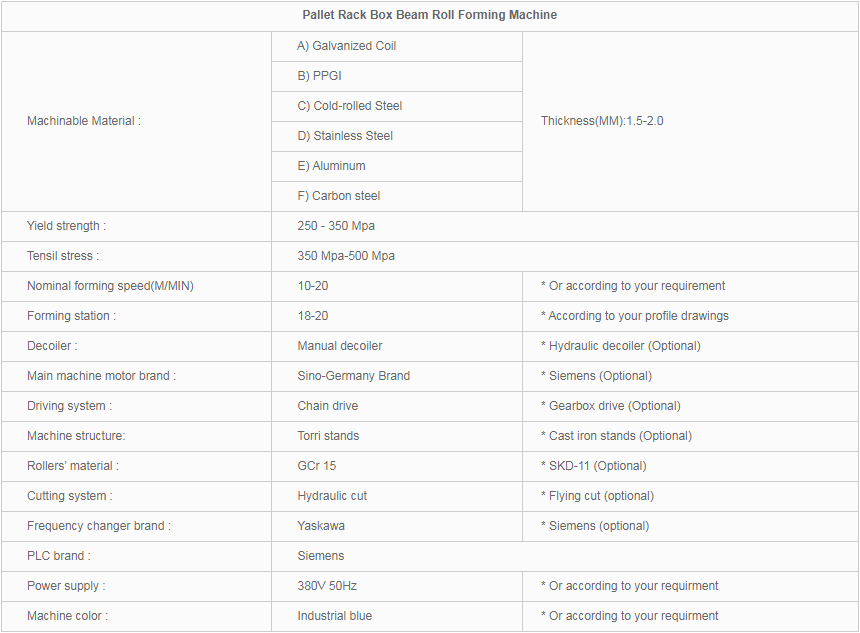

Technical Specifications

Key Features of the Box Beam Roll Forming Machine

This machine utilizes advanced roll forming technology to transform flat metal sheets into box beams with a closed, hollow structure, offering superior load-bearing capacity and structural integrity. It is ideal for industries such as construction, heavy machinery, logistics, and storage solutions.

Machine Structure:

Hydraulic Decoiler: Feeds the raw material into the roll forming machine.

Servo Feeder: Ensures precise and consistent material feeding.

Cold Roll Forming Unit: Sequentially forms the flat metal into a box beam shape.

High-Speed Punching Machine: Adds holes or slots in the beam for assembly purposes.

Welding Unit: Seals the edges of the box beam to create a strong, closed structure.

CNC Cutter: Accurately cuts the box beam to the required length.

Receiving Rack: Collects the finished box beams for packaging and distribution.

Applications:

Industrial Storage Systems: Box beams are widely used in shelving and racking systems, providing superior strength and stability for heavy-duty applications like pallet racks and warehouse shelving.

Construction and Infrastructure: In building structures, box beams are used in frameworks and supporting columns due to their high load-bearing capacity.

Logistics and Transport: Box beams can be used in the manufacturing of heavy-duty trailers and containers.

Bridges and Large-Scale Projects: They are critical components in bridge construction and other civil engineering projects requiring strong, durable materials.