Color steel glazed tile forming machine is a kind of equipment specially used for producing color steel glazed tiles. Color steel glazed tile forming machine forms metal coils (such as galvanized steel coils or aluminum zinc steel coils) into metal tiles with the appearance of traditional glazed tiles through a series of rollers and molds. This equipment is mainly used in the production of roof materials such as antique buildings, villas, garden buildings, etc.

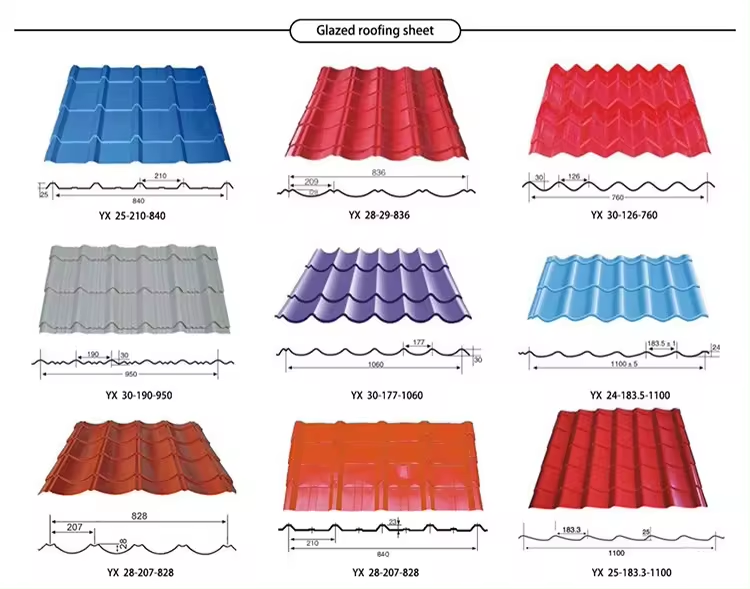

The following are several common types of color steel glazed tiles:

1. Wave-shaped color steel glazed tiles

Description: The tile surface is designed as a continuous wavy curve, with the streamlined feeling of traditional tiles.

Features: The wavy design can increase the drainage performance of the tile and is suitable for roofs in rainy areas.

Application: Widely used in residential houses, pavilions, antique buildings and structures with large roof slopes.

2. Romanesque color steel glazed tiles

Description: This type of tile is derived from the European architectural style. The tiles are arched and undulating, with the unique charm of Roman architecture.

Features: The surface curvature is large, the decorativeness is strong, and it has antique and European styles.

Application: Commonly used in villas, small landscape buildings and other buildings with high requirements for beauty.

3. Antique flat color steel tile

Description: This tile has a flat appearance, no obvious ripples on the surface, and is more concise and modern.

Features: Suitable for modern antique buildings, good waterproof performance, and suitable for buildings with small roof slopes.

Application: Used for some buildings that combine modern style with antique elements, and can also be used for the roofs and exterior walls of some industrial buildings.

4. Curved color steel glazed tile

Description: The arc design is similar to the traditional semi-cylindrical tile, and the tile has a continuous arc groove.

Features: Simulate the appearance of traditional ceramic glazed tiles, increase the three-dimensional sense of the roof, and is suitable for antique buildings.

Application: Suitable for antique pavilions, garden buildings and antique decorative buildings.

5. Trapezoidal color steel glazed tile

Description: This tile type is a staggered arrangement of trapezoidal or wavy shapes, and the tile has concave and convex trapezoidal ripples.

Features: The surface has a strong sense of geometry and lines, the structure is stable, and the pressure resistance is good.

Application: Suitable for commercial buildings, carports, industrial plants and other buildings that require high-strength roofs.

6. Double-layer color steel glazed tiles

Description: Double-layer tiles are made of two layers of tiles, the upper tiles are usually curved or wavy, and the lower ones are flat.

Features: The double-layer design enhances thermal insulation and wind resistance, and also improves the decorativeness of the roof.

Application: Used in buildings that require good thermal insulation, such as villas and high-end residential areas.

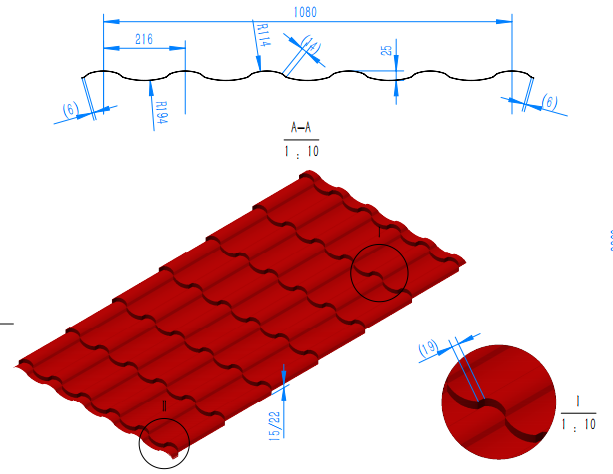

7. Chinese antique color steel glazed tiles

Description: This type of tile imitates the shape of traditional Chinese glazed tiles, has significant national characteristics, and the colors are mostly traditional red, blue or green.

Features: Bright colors, high-gloss glaze effect, good anti-corrosion and anti-rust performance, and strong decorative appearance.

Application: Used in antique gardens, temples, ancient buildings, etc., to meet the needs of traditional architectural aesthetics.

8. Metal imitation fish scale tiles

Description: The tiles are shaped like fish scales and are arranged closely to form a fish scale roof effect.

Features: good waterproof performance, strong decorative effect, tight structure suitable for low slope or curved roofs.

Application: used for pavilions, temples, garden buildings and other buildings with high decorative requirements.

Main features and advantages

Weather resistance: Color steel glazed tiles are made of galvanized and aluminum zinc materials, with special coating on the surface, which has good anti-corrosion, anti-ultraviolet and weather resistance.

Lightweight: Compared with traditional glazed tiles, color steel glazed tiles are light in weight, which reduces the load of the building structure and is convenient for construction and installation.

Strong decorative effect: a variety of tile types and color options, with antique style and modern aesthetics, suitable for various types of building needs.

Easy installation: Most color steel glazed tiles are modularly designed, easy to construct, and save labor and time costs.

Color steel glazed tiles have gradually become the preferred material for modern antique buildings due to their diverse appearance and superior performance. They can not only meet the requirements of waterproof and durable, but also give the building a strong artistic atmosphere.

The main components of our company’s color steel glazed tile forming machine are:

Decoiler: used to carry and convey raw steel coils, unroll the steel coils evenly and feed them into the forming machine.

Feeding System: guides the metal coils into the pressure rollers so that the coils can enter the forming process smoothly.

Roll Forming Stations: through a series of progressive pressure rollers, the flat metal coils are gradually pressed into tiles with the shape of glazed tiles.

Hydraulic Cutting System: automatically cuts the formed tiles according to the set length to ensure the precise size of each tile.

Control System (PLC Controller): The production process is controlled by the PLC system, and parameters such as tile length and production quantity can be set to ensure automated production.

Exit Conveyor: used to convey and stack finished tiles for easy collection and packaging.

Equipment Features

High efficiency: The color steel glazed tile forming machine can produce continuously, with high output, and is suitable for mass production.

Automatic control: Most molding machines are equipped with PLC systems, which can accurately control the tile size and production speed, reducing manual intervention.

Diversity: By changing the mold, the molding machine can produce different styles of colored steel glazed tiles, such as wavy, flat, trapezoidal, etc.

High precision: The hydraulic cutting system ensures the consistency of the length of the finished product, reduces material waste, and ensures stable quality.

Easy maintenance: The machine design is usually simple, easy to operate and maintain, and easy to maintain.