What Are Trapezoidal Roofing Sheet Machines?

High speed trapezoidal roofing sheet machine is a kind of industrial equipment specially used for the production of colour steel roofing sheet, widely used in the construction industry. These machines are designed to shape and form metal sheets, typically made from materials like galvanized steel, aluminum, or other alloys, into the trapezoidal profile that is known for its strength, durability, and weather resistance. This machine with its high-speed, efficient, accurate performance, has become one of the important tools in modern building construction.

TR35 is a very popular profile in Algeria, and the company decided to offer this product at a discount.

The following is a detailed introduction to the high-speed TR35 trapezoidal tile machine.

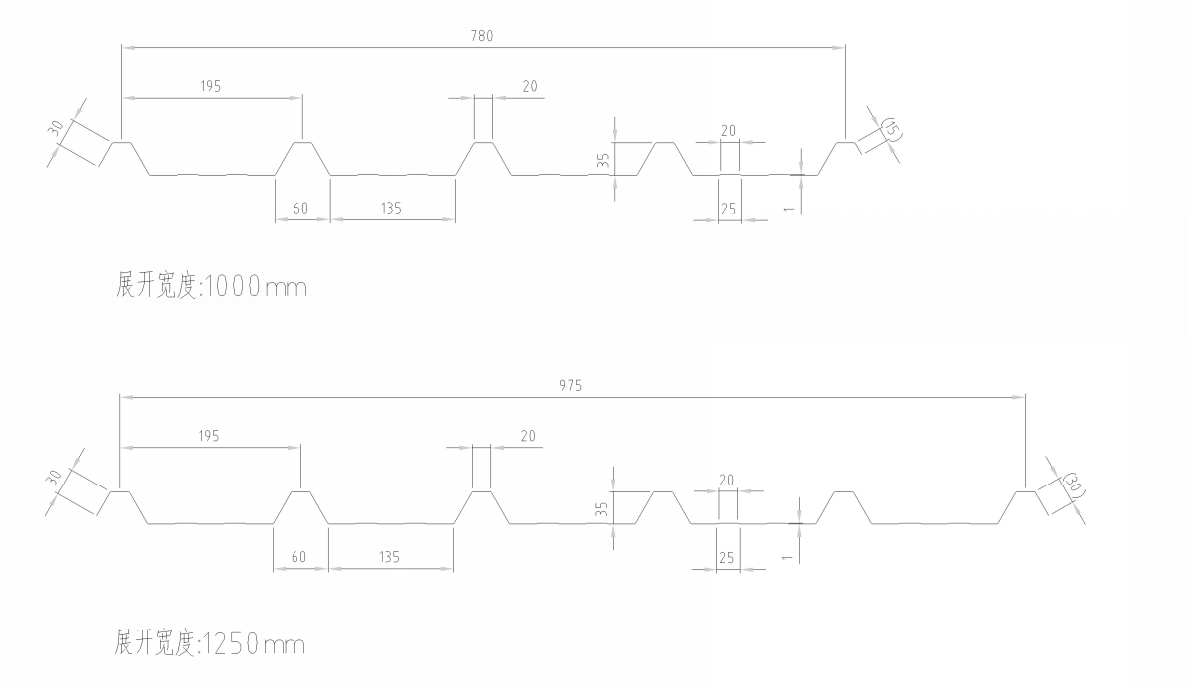

Profile drawing:

Main technical parameters:

rolling station: 25 rolling station

Machine structure: arch frame structure, more stable

Basic frame: 400H beam

Speed:40-50m/min

Motor power:22kw

Transimission by gear box

Servo track flying cutting

Key Features of Trapezoidal Roofing Sheet Machines

1.Roll Forming Process: The machine uses a roll forming process where flat metal sheets are fed into the machine and passed through a series of rollers that gradually bend the metal into the desired trapezoidal shape. This process ensures precision and consistency in the profile.

2.Material Compatibility: These machines are capable of working with a variety of materials, including galvanized steel, aluminum, and other metal alloys, making them versatile for different construction needs.

3.Automation: Modern trapezoidal roofing sheet machines are highly automated, featuring computerized control systems that allow for precise adjustments, high-speed production, and minimal human intervention.

4.Customizable Profiles: The machines can be adjusted to produce different trapezoidal profiles and sizes, catering to specific architectural requirements. Some machines also offer the ability to create custom designs.

5.Cutting Mechanism: Integrated cutting systems allow the machine to cut the sheets to the desired length after they have been formed, ensuring uniformity and reducing material waste.

Advantages of the High-Speed Roofing Sheet Machine

1.Rapid Production: Equipped with advanced transmission technology and sophisticated control algorithms, this machine enables fast, continuous production, significantly boosting overall efficiency.

2.Precision Forming: The machine utilizes meticulously designed molds and rollers to ensure that each roofing sheet is produced with exact size and shape specifications, thereby increasing product yield and quality.

3.Versatile Adaptability: Capable of handling various thicknesses and widths of color-coated steel plates, the machine can efficiently produce trapezoidal tiles in different specifications.

4.User-Friendly Operation: With a high level of automation and an intuitive interface, the machine is easy to operate, minimizing manual intervention and reducing production costs.

Application

The sheets produced by the high-speed trapezoidal steel tile machine are extensively used in roofing and wall cladding for industrial plants, warehouses, exhibition halls, stadiums, airports, stations, and various other buildings. These sheets offer excellent waterproofing and thermal insulation, while also providing an aesthetically pleasing appearance. Additionally, they are highly adaptable to different climatic conditions and environmental requirements.

As the construction industry continues to evolve, the demand for diverse building materials has grown. The high-speed trapezoidal steel tile machine, with its efficient and precise production capabilities, has become an essential tool in modern construction. Its versatility and performance provide significant support to the industry’s ongoing development, making it a vital component in building projects.

Why choose discount of trapezoide roofing sheet machine

1.Cost Savings: Purchasing a trapezoidal roofing sheet machine at a discount significantly reduces your initial investment, allowing you to allocate funds to other areas of your business or project.

2.Improved ROI: Lower upfront costs mean you can achieve a quicker return on investment. With reduced expenses, the machine can start generating profits sooner, making it a more financially sound decision.

3.Access to High-Quality Equipment: Discounts don’t necessarily mean compromised quality. You can often acquire top-tier machines at a lower price, ensuring you benefit from advanced technology and robust performance without paying full price.

How to Choose the Right Trapezoidal Roofing Sheet Machine

Assess Your Production Needs

Volume Requirements: Determine the quantity of roofing sheets you need to produce daily or monthly. Choose a machine that matches your production volume to ensure it meets your output demands.

Material Compatibility: Identify the types of materials you’ll be working with, such as galvanized steel, aluminum, or other alloys. Ensure the machine can handle the specific material thickness and width you require.

Evaluate Machine Features

Automation Level: Consider the degree of automation you need. Fully automated machines reduce manual labor and can increase production efficiency, but they may come at a higher cost.

Customization Options: Check if the machine allows for customization of sheet profiles and dimensions. Flexibility in adjusting settings can be crucial if you need to produce different sizes or shapes of trapezoidal sheets.

Cutting Mechanism: Look for a machine with an integrated cutting system that ensures precision and reduces waste by cutting sheets to the exact required length.

Consider Production Speed

Speed vs. Accuracy: High-speed machines can produce more sheets in less time, but ensure that speed doesn’t compromise the accuracy and quality of the finished product.

Project Deadlines: If you have tight deadlines, a faster machine will help you meet those deadlines without sacrificing quality.

Check for Durability and Reliability

Build Quality: Investigate the materials used in the machine’s construction. High-quality, durable components will ensure a longer lifespan and lower maintenance costs.

Brand Reputation: Research the manufacturer’s reputation. Machines from well-known, reliable brands are more likely to offer consistent performance and have better after-sales support.

Evaluate Ease of Operation

User Interface: A machine with an intuitive, user-friendly interface will make operation easier and reduce the likelihood of errors.

Training Requirements: Consider how much training your staff will need to operate the machine. Machines that are easier to learn and use can reduce downtime and improve overall productivity.Industry Professionals: If possible, consult with industry experts or colleagues who have experience with trapezoidal roofing sheet machines. Their insights can help you make a more informed decision.

Supplier Consultation: Engage with the supplier to discuss your specific needs and get their recommendations on the best machine for your requirements. They may offer insights into machine capabilities and customizations that you hadn’t considered.