The following is what customers say about us

We are impressed by ZTRFM’s colored stone tile production line. The equipment provided by the company is of excellent quality and uses advanced automation technology to ensure an efficient and stable production process. The equipment is easy to operate and maintain, which greatly improves our production efficiency. In addition, ZTRFM has performed well in after-sales service, responding to our needs in a timely manner, providing professional technical support, and ensuring the smooth operation of the production line. Overall, ZTRFM’s colored stone tile production line has provided strong support for our business development.

In this article, we will also briefly introduce the characteristics of the machine ordered by the customer

Sand spray steel roof sheet making lineSand spray steel roof sheet is a modern environmentally friendly roofing material with thebasic of 0.4 mm Al-zin coated steel. Covering color vermiculite surface which carried underthe high temperature technology. It is high-performance, stable, energy-efficient and easyoperation.

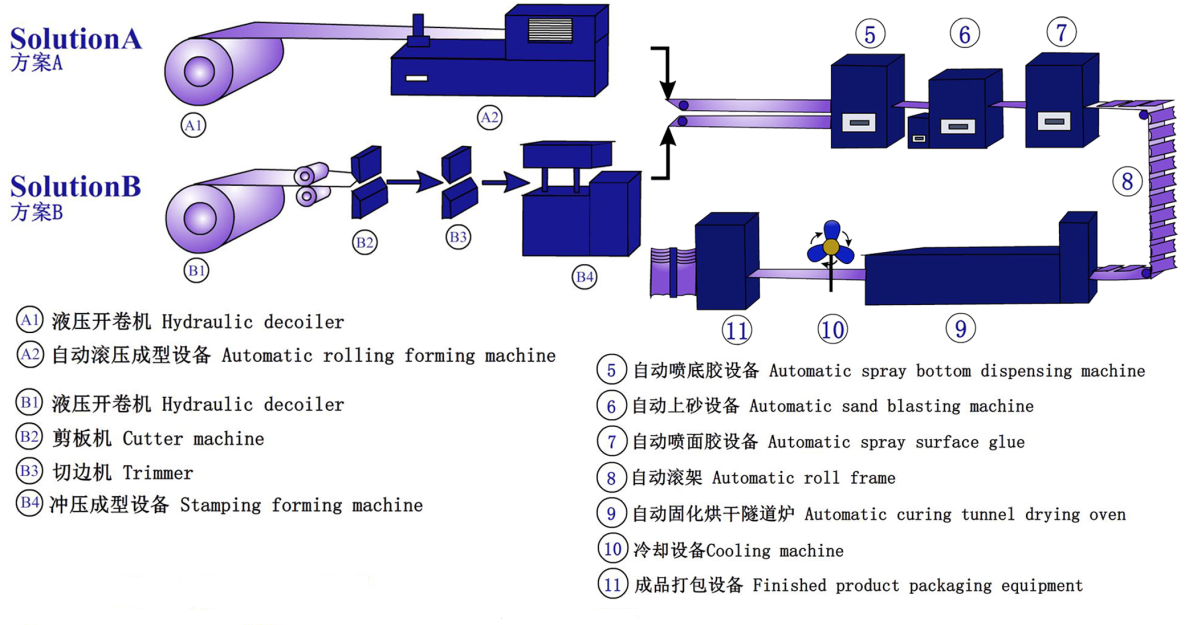

The sand spray steel roof sheet linecontains THREE main parts:

Part 1: Roof tile making machines

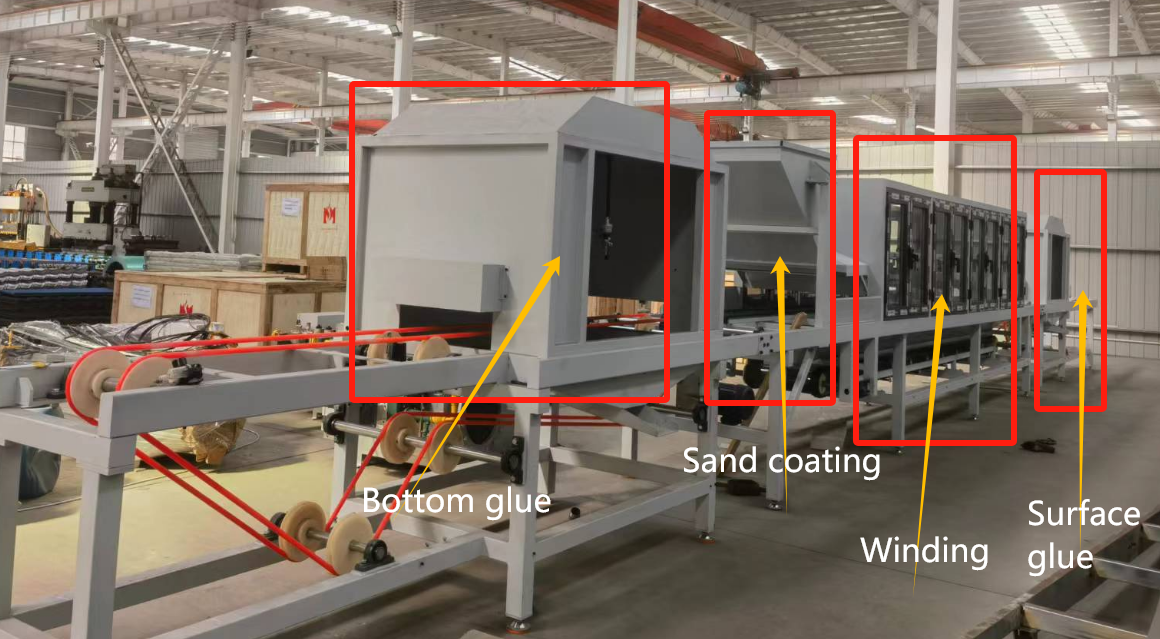

Part 2: Stone coated machines

Part 3:Accessories making machines

What is Colored stone tiles?

Colored stone tiles are a new type of advanced roofing material. They use galvanized steel sheets as the base material and are covered with sintered colored sand. They are beautiful, lightweight, durable and environmentally friendly, and have become a mainstream product in international roofing materials.

In the production process of colored stone tiles, key steps include raw material preparation, cutting and pressing, surface treatment, drying and curing, quality inspection and packaging, etc. Every link requires strict control to ensure the quality and performance of the final product.

Our company’s colored stone tile machines have notable features:

High degree of automation: Colored stone tile production lines are usually equipped with advanced automated control systems, which can automatically carry out feeding, pressing, sandblasting, coloring, drying and other processes, which greatly improves production efficiency and reduces manual participation.

High production efficiency: The color stone tile production line is reasonably designed and the efficient production process allows the production line to produce color stone tile products continuously and in large quantities to meet the market’s demand for high-quality roofing materials.

Stable product quality: The automation and precise control system of the colored stone tile production line ensures the consistency of the size, thickness, color and surface quality of each colored stone tile, reduces the defective rate, and ensures the reliability and durability of the product. .

Environmental protection and energy saving: The production line pays attention to environmental protection performance and reduces pollution emissions when designing. For example, the surface coating of colored stone tiles uses environmentally friendly materials to reduce the impact on the environment. At the same time, the production equipment has low energy consumption and significant energy saving effect.

Strong flexibility: The production line supports the production of colored stone tiles of various specifications and colors, and can produce products of different models and colors according to market demand. It has strong adaptability and meets the diverse needs of customers.

Strong durability: The production line equipment has strict material selection and processing technology, and the overall structure is sturdy and durable, able to withstand long-term high-intensity production, with low equipment failure rate and low maintenance costs.

Modular design: Many colored stone tile production lines adopt modular design to facilitate installation, disassembly and maintenance. This design makes it easier to adjust when the production line needs to be expanded or moved.