What is light gauge metal framing?

Light Gauge Metal Framing (LGMF) is a building frame system made of thin-walled steel (usually galvanized steel). It is mainly used for walls, floors and roofs of building structures, and has the advantages of high strength, light weight and fast construction speed. Compared with traditional wood frames, light gauge metal frames have better fire resistance, insect resistance and durability, while also reducing the overall weight of building materials.

The main components of lightweight metal frames include:

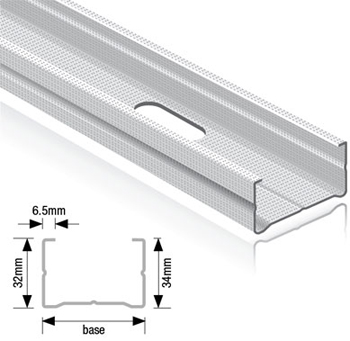

C-Studs: Mainly used in wall frames to provide structural support.

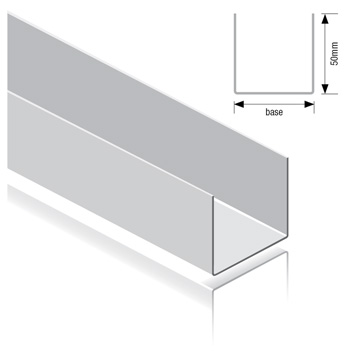

U-Track: Serves as the bottom and top rails of C-Studs for fixing and positioning.

Corner Studs: Used in corners and joints to enhance structural stability.

Bridging and Blocking: Used to enhance the stability of the frame and prevent lateral displacement.

Metal Panels: Used in walls and partitions to provide additional structural and thermal insulation functions.

These components work together to provide a strong and flexible building frame system.

Common sizes and specifications for light metal frames include:

C-sections:

Widths: 50 mm, 75 mm, 100 mm, 150 mm

Thicknesses: 0.84 mm, 1.00 mm, 1.15 mm, 1.50 mm

Heights: 90 mm, 150 mm, 200 mm

U-sections:

Widths: 50 mm, 75 mm, 100 mm, 150 mm

Thicknesses: 0.84 mm, 1.00 mm, 1.15 mm, 1.50 mm

Angles:

Dimensions: typically 50 mm x 50 mm, 75 mm x 75 mm

Thicknesses: 0.84 mm, 1.00 mm

Sheet metal:

Common thicknesses: 0.40 mm, 0.60 mm, 0.80 mm

Standard lengths: 2400 mm, 3000 mm, 3600 mm

Lightweight metal frames are widely used in the following fields:

Residential buildings: used for walls, partitions and roofs, providing efficient and lightweight structural solutions.

Commercial buildings: such as office buildings, shopping malls and hotels, favored for their fast construction and good stability.

Industrial facilities: suitable for warehouses, factories and production facilities, with corrosion resistance and durability.

Educational and medical facilities: schools, hospitals and clinics, providing flexible interior space layout.

Special purpose buildings: such as temporary buildings, exhibition halls and theaters, lightweight metal frames support fast erection and dismantling.

Why choose lightweight metal frames?

Lightweight and high strength: lighter than wood, but with comparable strength, reducing structural loads.

Fire resistance: metal is non-flammable, improving the fire safety of buildings.

Durability: not easily corroded or affected by pests, and has a longer lifespan.

Fast construction speed: prefabricated parts can be assembled quickly, shortening construction time.

Environmentally friendly: recyclable, reducing environmental impact.

Flexible design: suitable for a variety of architectural styles and structural requirements.

The installation steps and tips for light metal frames include:

Preparation stage:

Planning and measurement: Determine the design drawings of the frame, measure and mark the installation location.

Tools and materials: Prepare the required tools (such as electric drills, screwdrivers) and materials (such as C-shaped steel, U-shaped steel, connectors).

Installing rails:

Fix the bottom rail: Install the U-shaped steel bottom rail on the ground to ensure levelness.

Install the top rail: Install the U-shaped steel top rail on the top of the wall at a predetermined height.

Installing columns:

Cutting and placing: According to the design drawings, cut the C-shaped steel columns to the appropriate length and insert them between the bottom and top rails.

Fixing columns: Use screws or special clamps to fix the columns to the bottom and top rails to ensure verticality.

Connection and reinforcement:

Install beams: Install beams or reinforcements as needed to enhance structural stability.

Add connectors: Use connectors (such as bridges) at the joints to strengthen the frame connection and ensure firmness.

Check and adjust:

Horizontal and vertical check: Use a level to check the horizontal and vertical of the posts and frames, and adjust if necessary.

Ensure alignment: Confirm that all parts are aligned and connected securely.

Final fixation and inspection:

Fix all connections: Make sure all screws and connectors are tightened in place.

Check the overall structure: Check the stability and alignment of the frame to ensure it meets the design specifications.