Full Automatic C Purlin Roll Forming Machine

ZTRFM Full Automatic c purlin roll forming machine steel channel make machine consists of passive loading rack, leveling device, punching device, after forming cutting device, hydraulic station, computer control systems.

C section steel rolling machine equipment of c-beam bending finished with good pressure performance good flatness, automatic fixed-length cutting, automatic punching, high degree of automation, quick and easy installation.

C size:80-300mm

Material thickness:1.5mm-3mm

Profile Drawing for Reference:

The Application of the Finished Product:

Working Flow as Below:

Main Parameters of The C Purlin Machine:

Full Automatic C Purlin Roll Forming Machine |

|

|

Formed Material

|

PPGI,GI,AI

|

|

Thickness

|

0.40-0.80mm

|

|

Diameter of shaft

|

80mm solid shaft

|

|

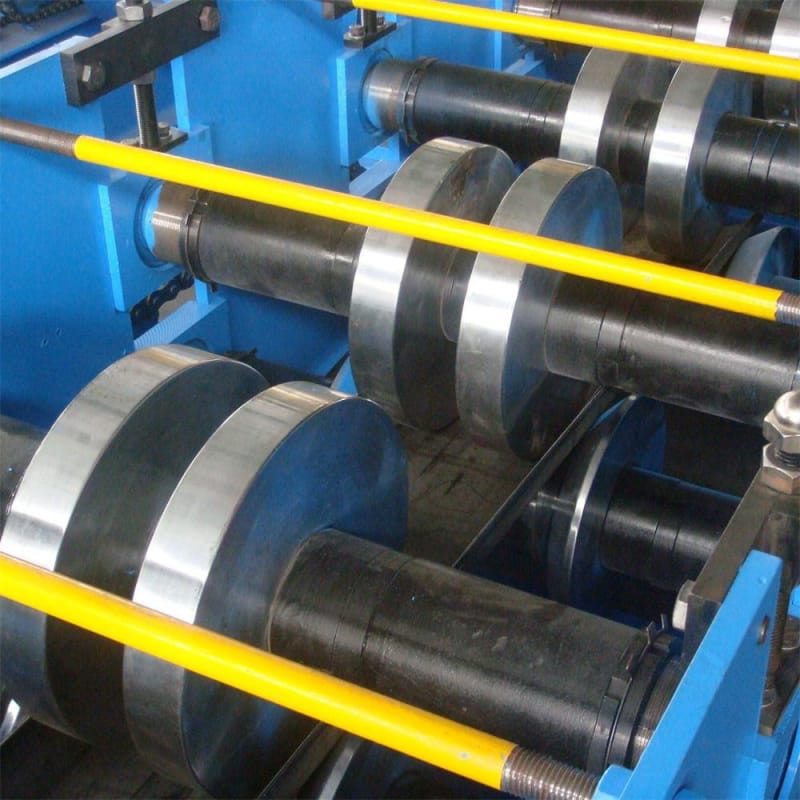

Material of rollers

|

Gcr 15 with quenched teeatment

|

|

Roller station

|

12 stations

|

|

Machine body frame

|

Metal steel welded

|

|

Drive

|

Chain transmission

|

|

Cutter

|

cr12mov material, no scratches, no deformation

|

|

Motor Power

|

11KW

|

|

Hydraulic system power

|

5.5KW

|

|

Voltage

|

380V 50Hz 3Phase(As your requirement)

|

|

Forming Speed

|

The speed is adjustable

|

Key Features of a Full Automatic C Purlin Roll Forming Machine

- Automation:

- The machine is fully automatic, meaning it requires minimal human intervention once set up.

- It features automatic feeding, cutting, and shaping, which increases production efficiency and reduces labor costs.

- High Production Speed:

- Full automatic machines can produce a large volume of C purlins in a short period.

- These machines often come with an adjustable speed feature, allowing for production to be tailored to the project requirements.

- Versatile Sizing:

- The machine can produce C purlins in different sizes (width, height, and thickness) by adjusting the rollers and cutters.

- Many machines are equipped with a quick-change system to easily switch between different purlin sizes without stopping the production line.

- Hydraulic Cutting System:

- Equipped with a hydraulic cutting mechanism, the machine can cut the purlins to the desired length with high precision after forming.

- PLC Control System:

- The machine operates with a Programmable Logic Controller (PLC) system, allowing for easy programming of the purlin dimensions, production speed, and quantities.

- The user-friendly interface ensures that operators can monitor and adjust settings in real-time, ensuring consistent quality.

- High Precision Forming Rollers:

- The forming rollers are made from high-quality, hardened steel to ensure accurate and consistent shaping of the C purlins.

- These rollers are designed to handle various steel grades and thicknesses, ensuring long-term durability.

- Material Handling:

- The machine can process galvanized steel, cold-rolled steel, or other metals with varying thicknesses, usually ranging from 1.5mm to 3.0mm.

- The coil feeding system is equipped with an automatic alignment feature to ensure precise material feeding into the machine.

Applications of C Purlins Produced by the Machine

C purlins are commonly used in the construction industry for the following purposes:

- Roofing and Wall Support: They serve as secondary structural members that support roofing sheets and wall panels.

- Steel Frame Buildings: Often used in pre-engineered buildings, warehouses, workshops, and garages.

- Bracing Systems: C purlins are used as bracing elements in construction to improve the structural stability of a building.