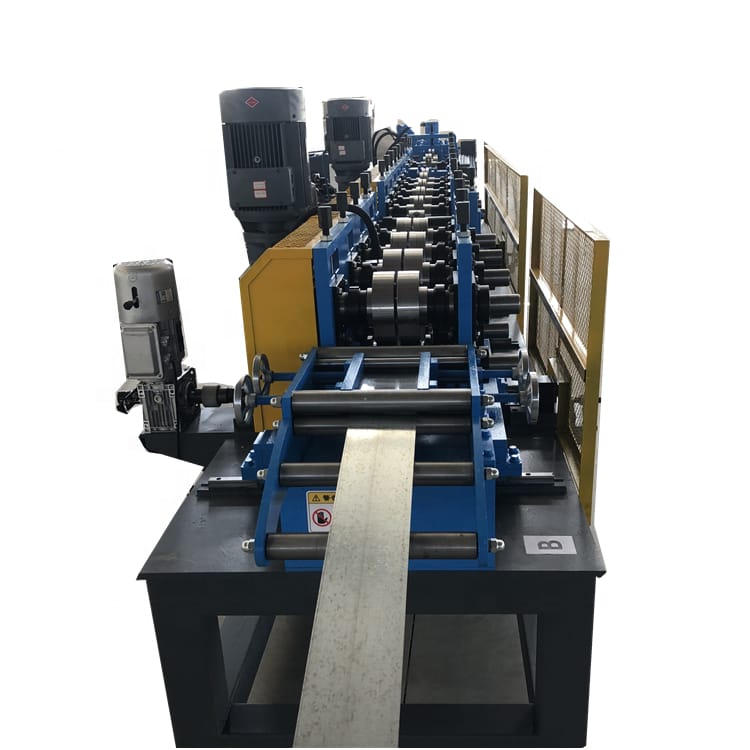

Galvanized metal steel CD UD system drywall profile channel roll forming machine

Profile drawing as below

Here is the C and U channel profile drawing and dimensions for your reference. Usually, one machine can produce both C and U sizes by adjust the roller spacer manually or automatically. C channel need punching holes, U channel no need.

|

Product

|

|

|

Details

|

Parameter

|

|

Raw material

|

Galvanized steel

|

|

Material thickness

|

0.4-0.9 mm

|

|

Cutting length

|

Adjustable

|

Afer-Sale Service

1.Payment: 30%T/T in advance and 70%balance after testing and before shipment.

2.Delivery: 50 working days after the deposit.

3.Validity time: 15 working days

4.After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

B: Training and service: the buyer should charge of visa, round-trip ticket, food and accommodation overseas and USD 80/person/day for salary.

C.The advantage of my factory: we have a team of skilled engineers and one group for after-sale service.

D: we will provide you the manual for installation, operation and maintenance in English.

2.Delivery: 50 working days after the deposit.

3.Validity time: 15 working days

4.After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

B: Training and service: the buyer should charge of visa, round-trip ticket, food and accommodation overseas and USD 80/person/day for salary.

C.The advantage of my factory: we have a team of skilled engineers and one group for after-sale service.

D: we will provide you the manual for installation, operation and maintenance in English.

|

Decoiler

Work type:Passive type Loading capacity:3 Tons Coil inner diameter:450-550 mm (adjustable) Quantity:1 set |

|

|

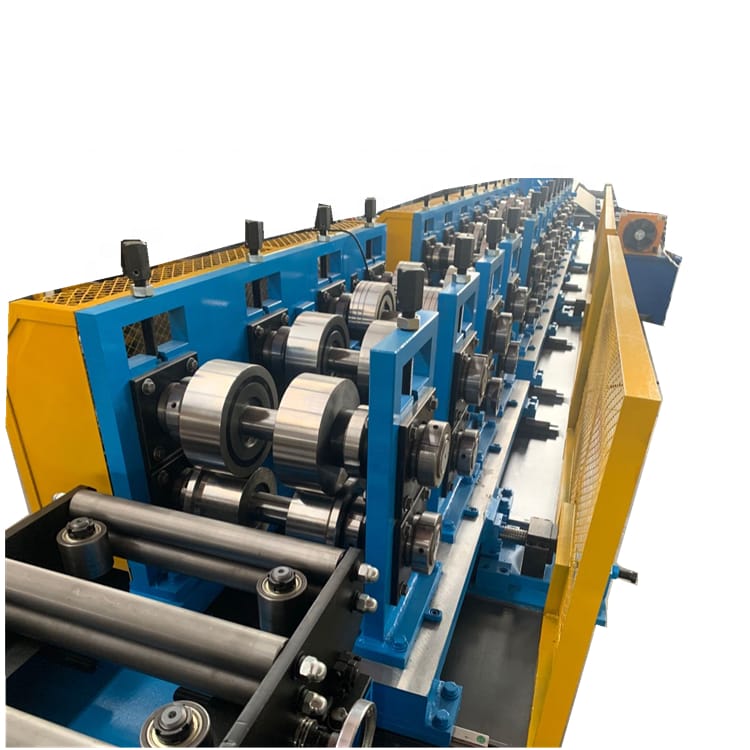

Roll Forming System

Feature;The one side machine frame can be move by PLC control to adjust the stud and truck dimension. Rolling shaft: Shaft material: 45# steel Shaft diameter: 50 mm Tempering treatment Roller: Roller material: Cr12 Quenched treatment Rolling station number:14 stations Work speed:0-40 m/min, if punching, 30m/min Machine frame:Vertical iron arch casting frame structure Bearing:Chinese famous brand Harbin Work power:5.5+5.5 kw Transmission:By chains |

|

|

PLC Control System

Frequency brand:Delta (original) PLC brand:Delta (original) Screen type:Touch screen & buttons Screen language:English/Chinese Encoder:Omron Low pressure electrical part brand:Schneider Function:Cutting length and quantity control, speed adjustment control |

|

|

Hydraulic System

Feature:The cutter have different holes according to the product dimension. PLC brand:DELTA brand Work type:Hydraulic track cutting with servo motor Servo motor power:2.3 kw Hydraulic power:3+5.5 kw Driving method:By pillar type Cylinder Cutter material:GB-Cr12 Cutting length tolerance:±1mm/3m Cutting feature:Automatic cutting after forming, no distorting. |