Introduction

Glazed tiles are ceramic tiles with a glossy surface coating that are both beautiful and practical. They are commonly used for roofing, flooring and wall cladding in residential, commercial and industrial buildings. They are widely used in Azerbaijan. Therefore, the demand for glazed tile machines in their country is also increasing.

Therefore, customers from Azerbaijan came to our company to order machines, which shows that the technical level of our equipment and product quality have been recognized by the international market.

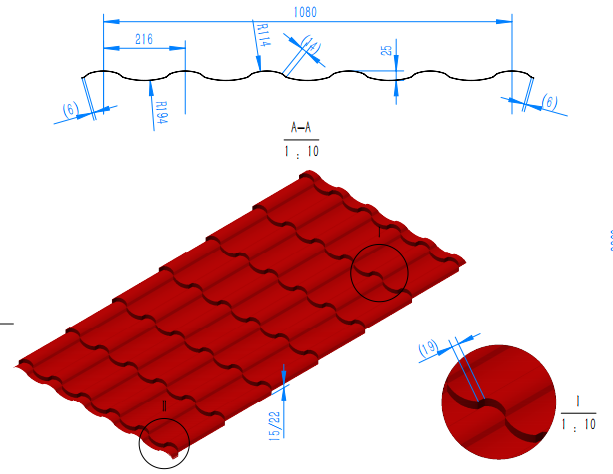

The following are some specific models and parameters of the glazed tile machines ordered by Azerbaijan customers in our factory

Characteristics of glazed tiles

As a traditional building material, glazed tiles are often used for roof and wall decoration due to their unique color, which can add beauty and artistic value to buildings.

Main features include:

1. Surface treatment: glazed tiles can have a glossy surface, making their surface shiny and reflective, or a matte surface, making their appearance softer and more modern.

2. Durability: glazed tiles are produced from steel plates, which are highly resistant to scratches and abrasions, can withstand severe wear and tear, and are suitable for areas with high traffic.

Waterproofness: The surface of glazed tiles is smooth, which also helps prevent mold growth and is easy to maintain and clean.

Working Principle and Technical Features of the Glazed Tile Roll Forming Machine

The glazed tile roll forming machine is designed to produce glazed tiles efficiently through a series of automated processes.

The working principle involves several key steps:

- Raw Material Input: Steel coils, typically coated or pre-painted, are fed into the machine.

- Guiding System: The material is guided into the machine through adjustable guiding equipment, ensuring proper alignment.

- Roller Stations: The steel strip passes through multiple sets of rollers, each set gradually bending the steel into the desired tile profile.

- Progressive Shaping: Each roller station progressively shapes the material, ensuring precision and consistency in the final product.

- Pressing Mechanism: The machine includes a pressing section that applies the necessary pressure to create the glazed tile’s specific contours and patterns.

- Embossing Rollers: Specialized rollers may be used to emboss additional designs or textures onto the surface of the tiles.

- Automatic Cutting System: Once the desired length of the tile is achieved, an automated cutting system, typically using hydraulic or pneumatic shears, cuts the tiles accurately.

- Length Control: The cutting length is controlled by a computer system to ensure uniformity and precision.

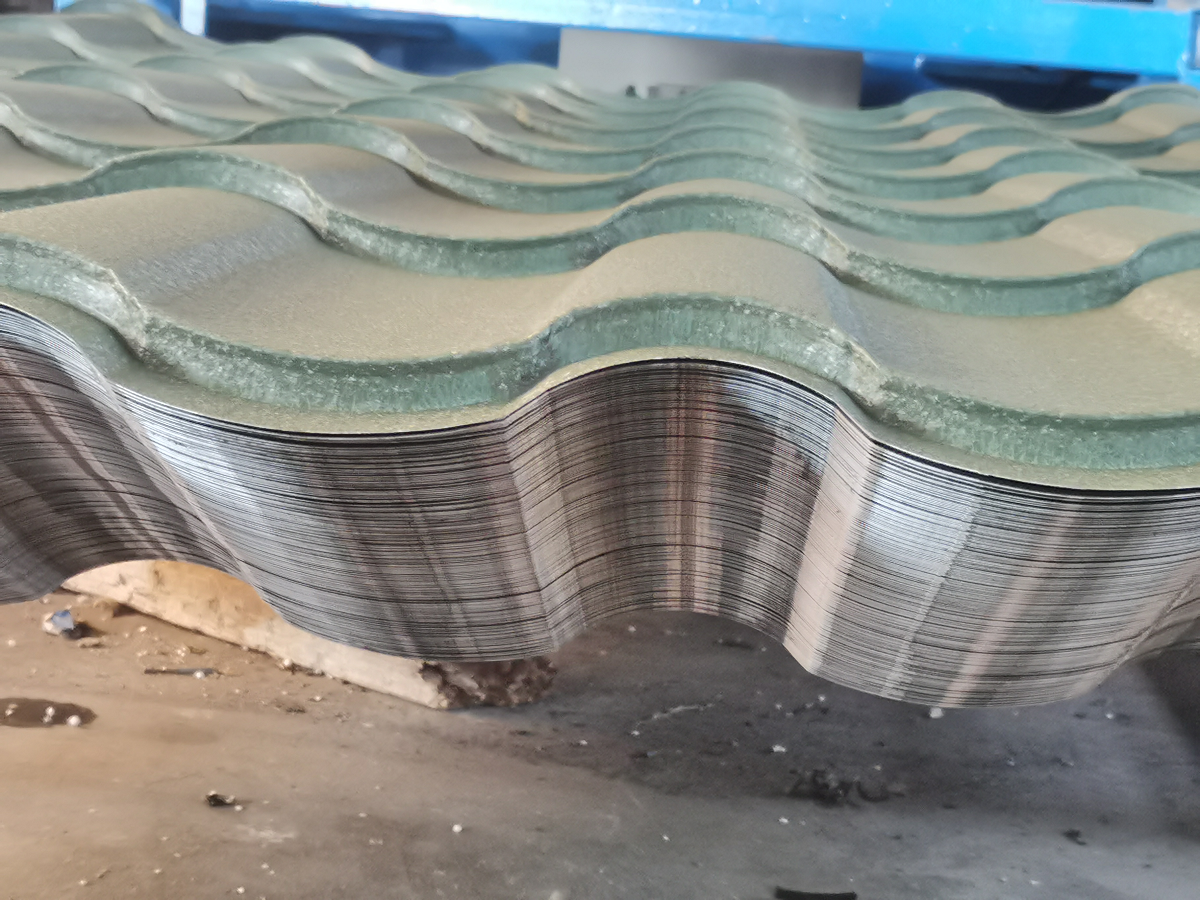

- Discharge Section: The finished tiles are then conveyed to the discharge section where they are collected and prepared for packaging.

- Stacking and Packaging: Tiles are often automatically stacked and packaged, ready for transportation and installation.

Market Demand for Glazed Tiles in Azerbaijan

In the context of international trade and globalization, Chinese manufacturing enterprises have not only promoted their own development by exporting high-quality equipment, but also provided high-quality solutions for the construction industry around the world. As a country located at the junction of Europe and Asia, Azerbaijan has a rich history and culture, its architectural style is unique, and its requirements for building materials are also high.

Application characteristics of glazed tiles:

Indoor: Glazed tiles are widely used in flooring, wall coverings, and kitchen and bathroom surfaces due to their durability, water resistance, and easy maintenance.

Outdoor: Glazed tiles are used for exterior walls and roofs to add aesthetic value and weatherproofing to residential buildings.

Conclusion

Zhongtuo Cold Bending Company’s equipment can meet the needs of the local market and produce beautiful glazed tile products, which is of positive significance for promoting economic cooperation and technological exchanges between the two countries.

In addition, this also reflects the efforts and achievements of Chinese companies in continuously improving their own R&D capabilities and manufacturing standards under the “going out” strategy, actively participating in international competition, and promoting the transformation of “Made in China” to “Made in China”. With the advancement of the “Belt and Road” initiative, I believe that more Chinese companies and products, like Zhongtuo Cold Bending Company, will demonstrate the charm and strength of Chinese manufacturing in countries along the route and even in the global market.