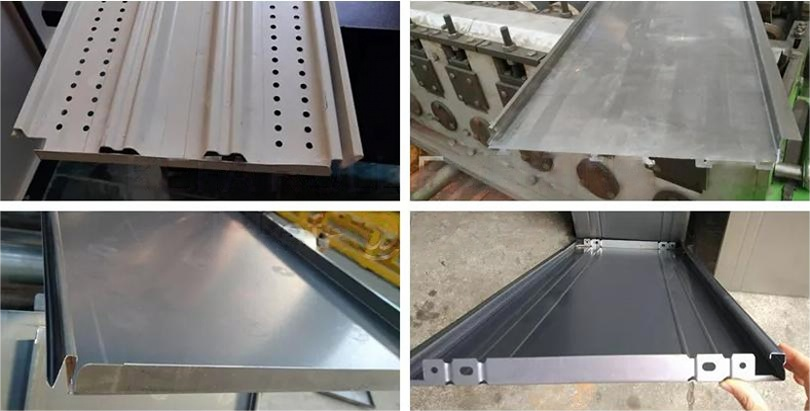

This mainly used in warehouses,supermarkets,shopping malls,display,display goods,such as one of the light shelf components.

Selective Pallet Racking rolling forming machine is designed to make the pallet racking part in batch fully automatically.

Why Choose Our Shelf Panel Roll Forming Machine & Upright Pallet Rack Roll Forming Machine With Hydraulic Punching?

1.Professionally Design According To The Drawing Profile.

2.Size Adjustable Fully Automatic.

3.Panel Width Could Be Adjusted Easily.

4.Pillar Stands Design To Make Sure Machine Working Speed And Long Time To Use.

5.Transmission By Gear, Working Steadier.

6.All The Electrical Elements are Best Brand.

As part of our continuous commitment to improving product quality and performance, we have developed the Heavy Duty Pillar Making Machine and T-Beam Shelf Making Machine. These machines are designed to produce high-strength components required for heavy-duty shelving systems, including pillars and T-beams, which form the structural backbone of industrial racks, warehouse storage, and large-scale shelving units. Combining robust technology and precise engineering, these machines offer an advanced solution to meet the ever-growing demand for durable and reliable shelving systems in industries like warehousing, retail, and logistics.

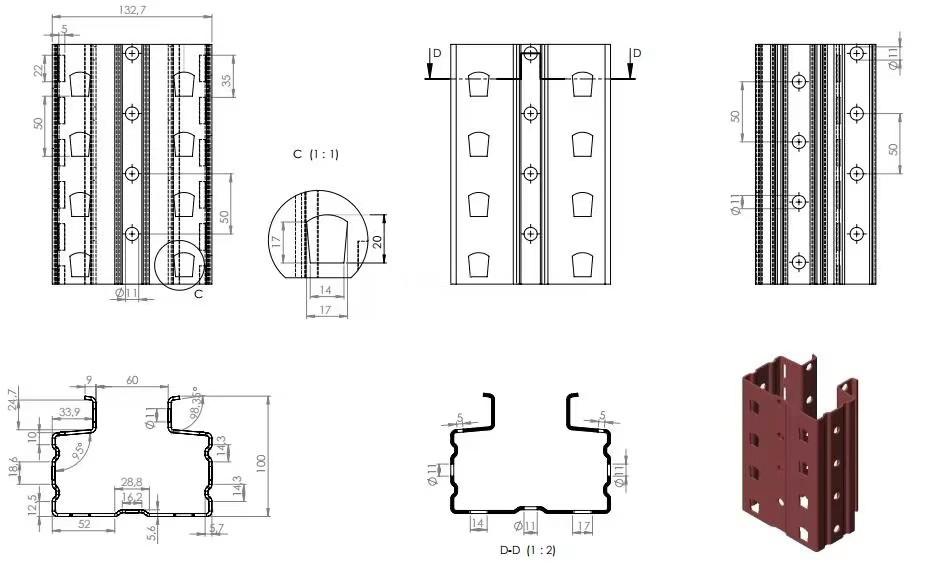

Heavy Duty Pillar Making Machine

This machine is engineered to produce heavy-duty pillars that serve as the vertical support structure in shelving systems designed for carrying significant loads. These pillars are critical in ensuring stability and durability in heavy-duty shelving, pallet racks, and industrial storage solutions.

Key Features:

Raw Material: High-strength cold-rolled or hot-rolled steel, galvanized steel, and stainless steel.

Raw Material Thickness: 1.5-3.0 mm for superior load-bearing capacity.

Production Speed: Up to 10 m/min, ensuring efficient high-volume production.

Material Input Width: Adjustable to cater to various pillar sizes.

Pillar Profile: Can produce multiple pillar shapes, including square, rectangular, and custom profiles, based on shelving system requirements.

Machine Components:

Hydraulic Decoiler: Supplies raw material into the production line.

Precision Punch Feeder: Ensures accuracy in hole punching for assembly.

Cold Roll Forming Section: Shapes the raw material into sturdy pillar profiles.

CNC Cutter: Cuts the pillars to desired lengths with high precision.

Receiving Rack: Collects finished pillars.

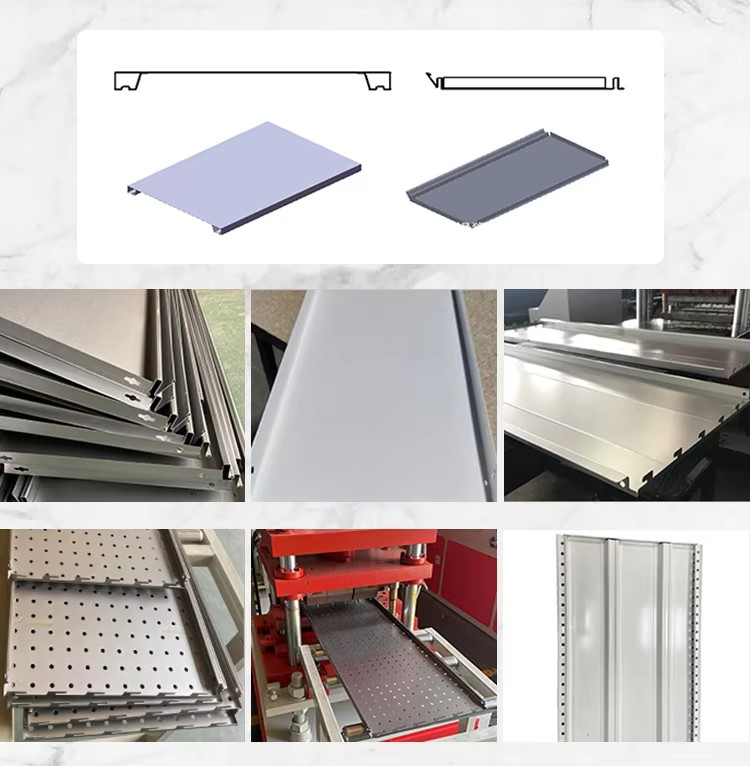

Final Product Display

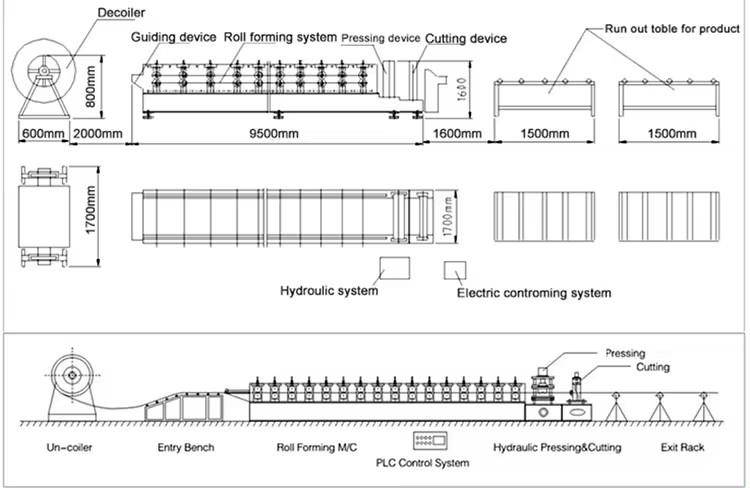

Processing flow

Uncoiling→Feeding material into machine→Roll forming→Auto cutting→Products receiving table

T-Beam Shelf Making Machine

The T-Beam Shelf Making Machine is designed to manufacture T-beams, which are horizontal support structures crucial for shelving systems that need to support heavy loads. These T-beams are widely used in warehouses, distribution centers, and retail outlets to support large quantities of goods.

Key Features:

Material: Cold-rolled or hot-rolled steel, galvanized steel, stainless steel.

Raw Material Thickness: 1.5-2.5 mm, providing high durability and load capacity.

Production Speed: 8-12 m/min for fast and efficient manufacturing.

Beam Length: Adjustable to meet different shelving dimensions.

Customizable Profiles: Capable of producing various T-beam profiles to suit customer specifications.

Machine Components:

Hydraulic Decoiler: Ensures continuous feed of raw material.

Roll Forming Section: Forms raw material into T-beam shapes with precision.

Hydraulic Punching System: Punches holes for bolts and connectors.

CNC Shear: Precisely cuts the T-beams to the required lengths.

Output Table: Receives and stores finished products.

Applications:

Industrial Racking Systems: Heavy-duty pillars and T-beams are essential in the construction of racks designed for storing pallets and bulky goods.

Warehouse Storage: These machines provide the structural components for high-strength shelving in warehouses, ensuring safety and longevity.

Retail and Commercial Shelving: Suitable for producing components for large-scale shelving in department stores, supermarkets, and home improvement stores.

Distribution Centers: The heavy-duty pillars and T-beams provide the necessary structural integrity to handle high-volume goods storage and logistics operations.

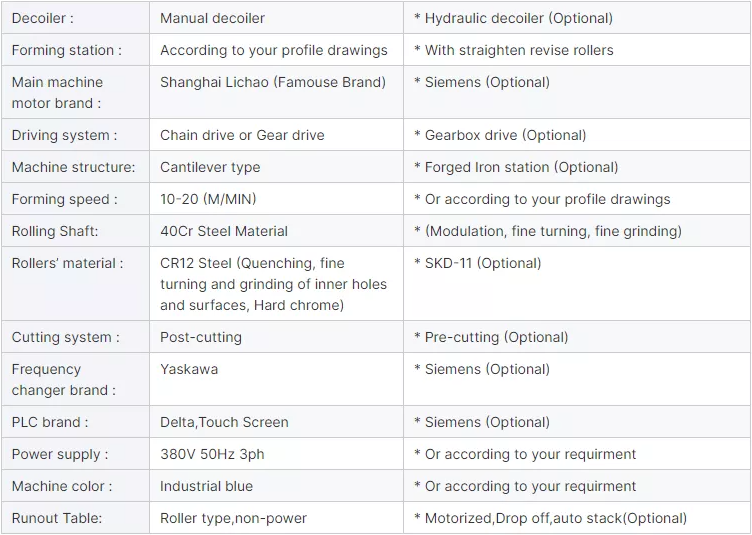

Technical Specifications:

Heavy Duty Pillar Making Machine:

Material Thickness: 1.5-3.0 mm

Material Type: Cold-rolled steel, hot-rolled steel, galvanized steel

Production Speed: Up to 10 m/min

Pillar Profiles: Customizable

Pillar Length: Variable

T-Beam Shelf Making Machine:

Material Thickness: 1.5-2.5 mm

Material Type: Cold-rolled steel, hot-rolled steel, galvanized steel

Production Speed: 8-12 m/min

Beam Length: Customizable

T-Beam Profiles: Multiple profile options available

Usage scenario diagram