The High-Speed Automatic Corner Stud Roll Forming Machine is an advanced, fully automated system designed to manufacture high-quality metal corner studs and tracks used in drywall construction. These metal components provide robust and stable support for drywall systems, ensuring long-lasting durability and strength. By leveraging cutting-edge roll forming technology, this machine produces continuous lengths of studs and tracks with high accuracy and consistency, making it an essential tool for construction projects.

Key Features of the High-Speed Automatic Corner Stud Roll Forming Machine

- Fully Automated Production: With advanced computerized controls, automatic feeding, and cutting systems, the machine operates efficiently, reducing the need for manual labor and minimizing production costs.

- Precision Roll Forming: The machine gradually forms metal strips into the desired stud or track profile through a series of precision rollers. It can create various sizes and shapes, depending on the project requirements.

- Durable Construction: Built with high-quality materials, this roll forming machine is designed for longevity and reliable operation, even under heavy use in industrial environments.

- High Speed and Accuracy: Capable of reaching speeds up to 45 meters per minute, the machine ensures fast production without compromising on quality. Servo motor control ensures accurate punching and cutting during the process.

- Versatile Profile Production: Designed to produce both standard drywall studs and tracks, this machine can also manufacture specialized profiles, such as slotted tracks, with high precision.

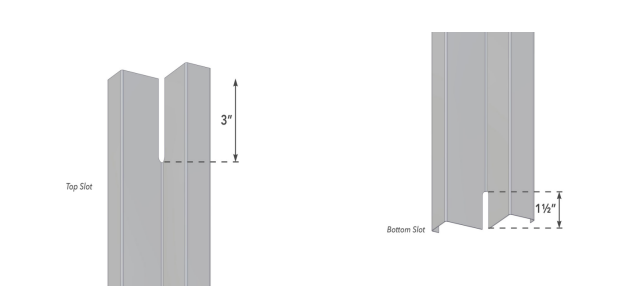

What is a Corner Stud?

A corner stud is a structural component used in drywall framing systems to form inside corners. The unique design of corner studs streamlines assembly, reducing the number of components needed and simplifying the installation process. By minimizing sharp edges and complex assembly requirements, corner studs ensure safe, efficient, and stable drywall installations.

Applications of Corner Studs:

- Inside Corners: Provides a strong and smooth connection at the corner junctions of drywall systems.

- Shaftwall Assemblies: Corner studs are integral to JL corner shaftwall assemblies, offering enhanced support and stability.

Advantages of the Corner Stud Roll Forming Machine

- Increased Productivity: With its fully automated design and fast production speed, the machine significantly boosts output while lowering labor costs.

- Precise Control: The servo motor control ensures accurate forming, punching, and cutting, producing high-quality studs and tracks that meet exact specifications.

- Time-Saving Installation: The corner studs produced by this machine simplify the installation process by reducing the number of components needed, saving both time and labor on-site.

- Durability: Using GCr12mov steel rollers and a 45# tempered steel shaft, the machine offers exceptional durability, ensuring a long service life and consistent performance.

- Environmental Benefits: Metal studs and tracks are made from galvanized steel, which is 100% recyclable and helps reduce environmental impact in construction projects.

Technical Specifications

- Material Thickness: 0.5 to 1.5 mm (galvanized steel plate).

- Roll Forming Speed: Up to 45 meters per minute, ensuring high-speed production.

- Main Motor Power: 11 kW x 2, plus three additional linear motors for efficient operation.

- Roller Material: GCr12mov steel, providing high wear resistance and longevity.

- Number of Rollers: 16 rollers with one rib and one additional dotting station for added customization.

- Punching and Cutting: Servo-flying hydraulic cutting system for precise, burr-free cuts, enhancing the quality of the final product.

- Frame Type: Memorial arch frame, 30 mm thick for enhanced machine stability and durability.

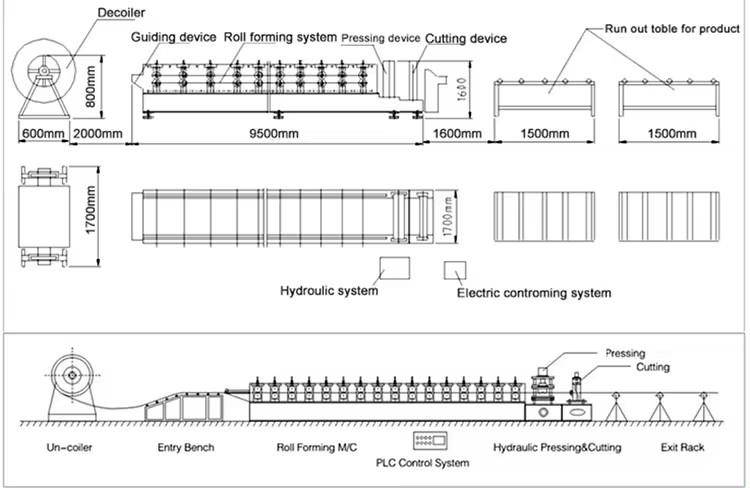

Work Flow

- Uncoiling: The machine uses a double head uncoiler for quick coil changes, improving productivity by minimizing downtime.

- Roll Forming: The metal strip is gradually shaped into the desired stud or track profile through a series of precisely aligned rollers.

- Punching and Cutting: Using a servo-flying hydraulic cutting system, the machine accurately punches and cuts the studs and tracks to the desired length without stopping the production line.

- Stacking and Packing: Once formed and cut, the finished studs and tracks are automatically stacked and packed, streamlining the entire process.

Design Idea

The machine is designed to efficiently produce both standard drywall studs and tracks, as well as slotted tracks through a specialized punching process. The servo motor control allows for precise adjustments during roll forming and punching, ensuring that the final product meets strict dimensional and quality standards.

Applications of the High-Speed Automatic Corner Stud Roll Forming Machine

- Steel Buildings: Metal corner studs and tracks are commonly used in the internal framework of steel buildings, which are preferred for their strength, durability, and cost-efficiency.

- Drywall Construction: Corner studs and tracks play a critical role in providing stable support for drywall systems in both residential and commercial buildings.

- Storage and Work Spaces: Steel framing is widely used in the construction of storage facilities, workspaces, and even living accommodations due to its ability to withstand high loads and adverse conditions.

- Green Construction: Steel is a green building material because it is 100% recyclable, energy-efficient, and manufactured to strict specifications, making it an environmentally responsible choice for construction projects.

Benefits of Steel in Construction

- Strength and Stability: Steel provides excellent structural integrity and can be easily modified for design flexibility.

- Cost-Effective: Steel is durable, low-maintenance, and cost-efficient, making it a popular choice in construction.

- Environmentally Friendly: Steel is recyclable and energy-efficient, contributing to sustainable building practices.

- Resistance to Mold and Pests: Steel does not warp or attract mold, ensuring a longer lifespan for structures built with steel framing.

The High-Speed Automatic Corner Stud Roll Forming Machine is an essential tool for producing high-quality metal corner studs and tracks. With its advanced features, precision control, and high-speed capabilities, it is the ideal solution for drywall construction projects looking to optimize production, reduce costs, and ensure long-term performance.