Metal framing include furring channel,carrying channel,studs,tracks,wall angle,and main frame channel used in concealed grid gypsum ceiling of light weight structure.Two most commonly used frames are metal U Track,used as the horizontal framework of stud partitions,in conjunction with vertical studs(C Studs).

Strong,lightweight,simple to install,and available in a variety of sizes,metal studs and channels provide for the ideal and cost-effective wall and ceiling applications when used with several layers of gypsum board.

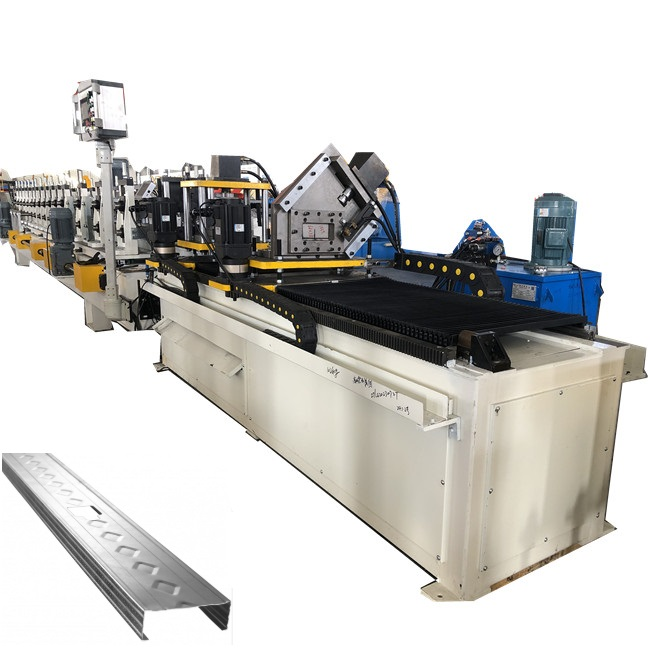

Key Features of the High-Speed Seismic Drift Track Machine

Automated Control and High-Speed Operation

With PLC-controlled systems (from trusted brands like Siemens or Panasonic), this machine offers precision manufacturing at speeds of up to 45 meters per minute, optimizing both productivity and accuracy. The servo motor control ensures smooth operation, while the hydraulic overload protection safeguards the machine.

Customizable Design

The machine can produce C Stud and U Track profiles with options for punching holes and embossing logos, offering a wide range of design possibilities. By adjusting the machine’s settings, manufacturers can create seismic drift tracks in various sizes and shapes, depending on project needs.

Durable Construction and Precision Engineering

The steel plate welded fuselage ensures rigidity, while precision ground gears and shafts provide stable and low-noise operation. With GCr12mov steel rollers and a memorial arch frame, the machine is built for longevity and consistent performance in high-volume production.

Efficient Material Usage

Seismic drift tracks produced by this machine allow for head-of-wall deflection and fire ratings for both interior and exterior walls. The machine’s efficient design minimizes material waste while maintaining superior product quality.

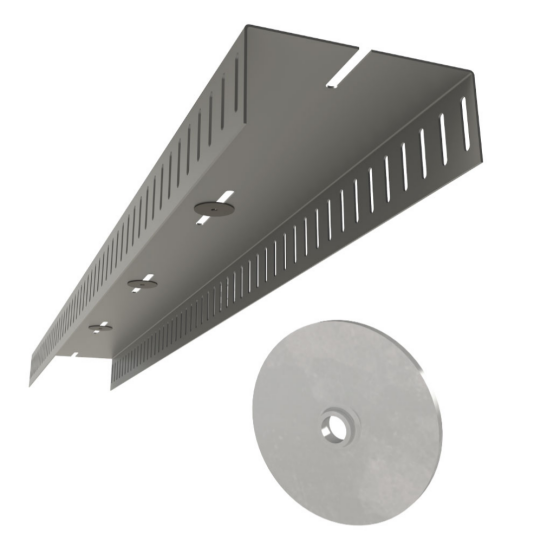

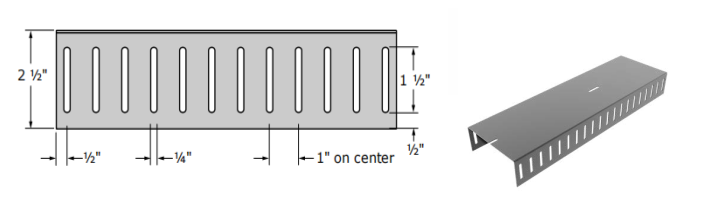

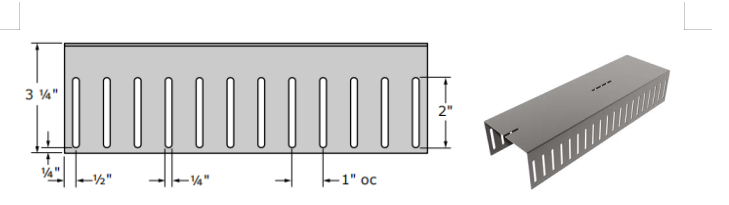

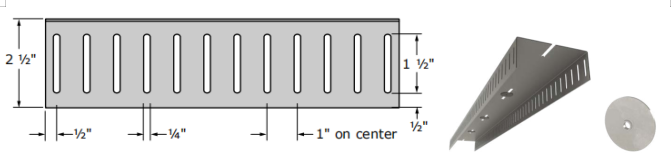

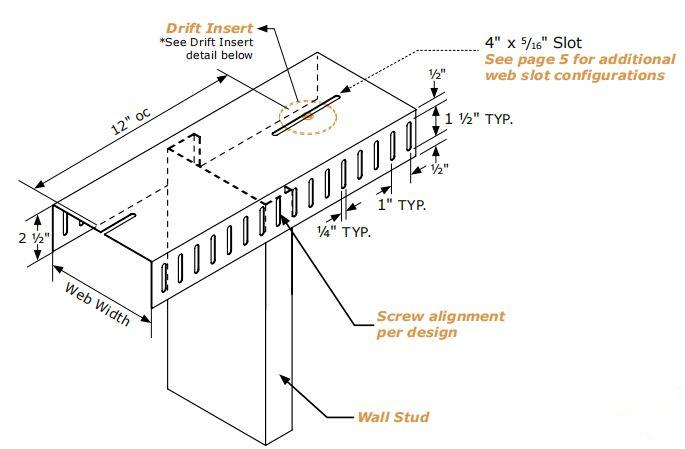

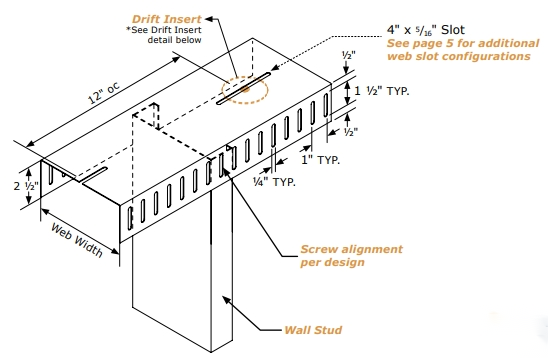

Here is one drawing profile and finished product:

Types of Seismic Drift Tracks

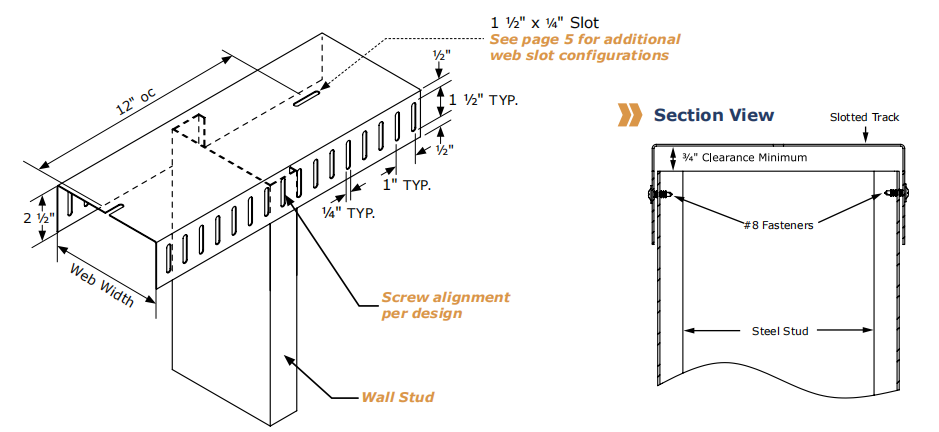

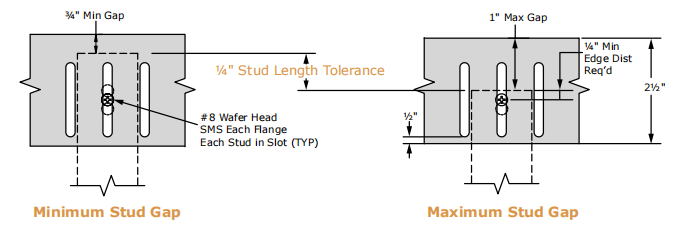

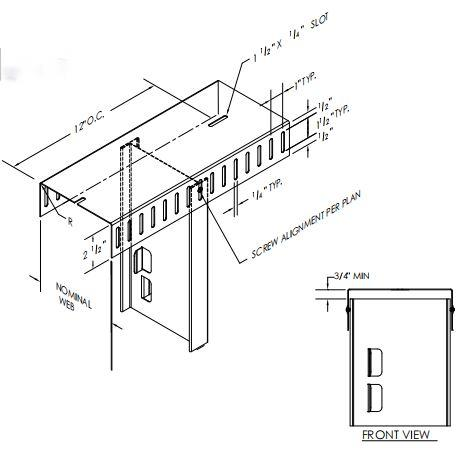

SLT – Standard Slotted Leg Track

The SLT features 2½” flanges with 1½” long vertical slots, designed to accommodate 1½” of vertical movement. This track type is ideal for projects that require standard seismic drift capabilities.

Specifications

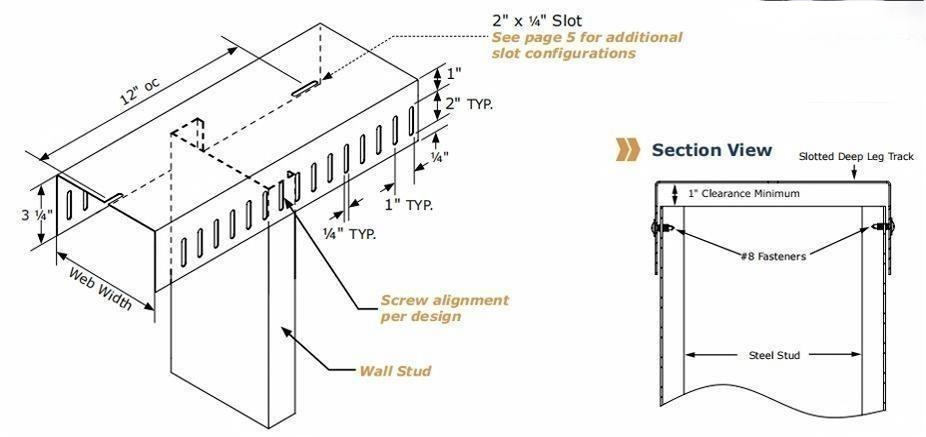

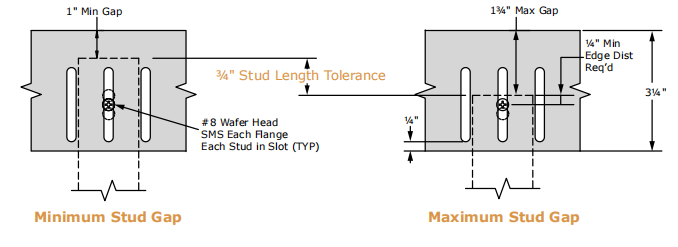

SDLT – Slotted Deep Leg Track

The SDLT features 3¼” flanges and 2” long vertical slots, allowing for 2” of vertical movement. This deep leg track is suitable for structures requiring more extensive drift and deflection movement.

Specifications

D – Seismic Drift Track

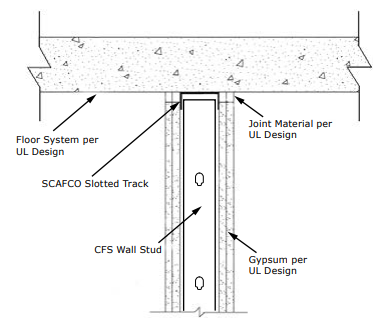

The Seismic Drift Track (D) is engineered to allow for lateral movement while accommodating head-of-wall deflection and fire ratings. It features 2½” flanges with vertical slots spaced at 1” intervals for optimized deflection.

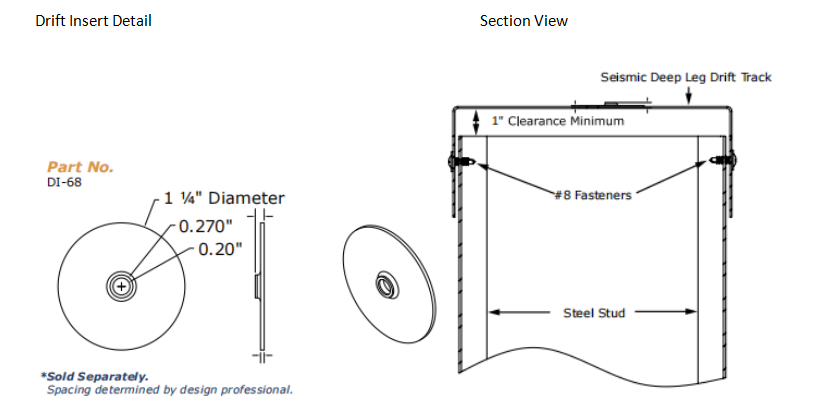

DD – Deep Leg Seismic Drift Track

The Deep Leg Seismic Drift Track (DD) offers greater lateral movement and fire protection with 3¼” flanges and 2” vertical slots. The track comes with an extruded metal insert for a more secure connection to the main structure.

I-Stud Shaftwall System

UL Head-of-Wall Joint Systems Design Numbers

Advantages of the High-Speed Seismic Drift Track Roll Forming Machine

Fire-Rated Deflection System

The machine produces seismic drift tracks that are UL Classified in over 80 approved fire-rated systems, ensuring high safety standards for both commercial and residential projects.

Custom Shapes and Sizes

Manufacturers can create custom seismic drift track designs, including varying slot sizes, widths, and thicknesses, to meet the specific requirements of each project.

Positive Wall Attachment

The seismic drift tracks produced by the machine provide a positive attachment for walls, enhancing overall structural strength and integrity.

Labor and Cost Efficiency

The machine’s automated design, high-speed production capabilities, and easy installation of the final product reduce labor costs and improve production efficiency.

Seismic drift track features and applications:

- Fire-rated deflection system

- UL Classified in over 80 approved fire-rated systems

- Standard Slotted Track allows up to 1½” of vertical movement

- Custom shapes and slot sizes available

- Custom widths and thicknesses available

- Positive attachment provided for wall strength

- Absorbs head-of-wall and floor extension or compression movement

- Integrated with traditional wall systems

- Easy installation reduces labor costs

Material / Product Specification:

Nonstructural (Drywall) Products:

- 18-30 mil: 33 ksi

- 25EQ: 50 ksi

- 20EQ, 30EQD: 57 ksi…………ASTM A1003/A653, C645

Structural Framing Products:

- 33-43 mil: 33ksi

- 33EQS, 43EQS: 57 ksi

- 54-127 mil: 50 ksi…………ASTM A1003/A653, C955

Coating Specification

Nonstructural (Drywall) Products:

- 25EQ, 20EQ, 30EQD, 18-30 mil: G40…………ASTM A1003/A653, C645

Structural Framing Products:

- 33EQS, 43EQS, 33-97 mil: G60…………ASTM A1003/A653, C955

Note: Contact ZTREM for heavier coating thickness availability.