Introduction

Roll forming is a continuous bending operation in which a long strip of sheet metal (typically coiled steel) is passed through sets of rolls that incrementally shape it to the desired cross-section. The process is highly efficient and capable of producing complex profiles with a high degree of accuracy and repeatability.

Introduction to Hot Rolled Steel and Cold Rolled Steel

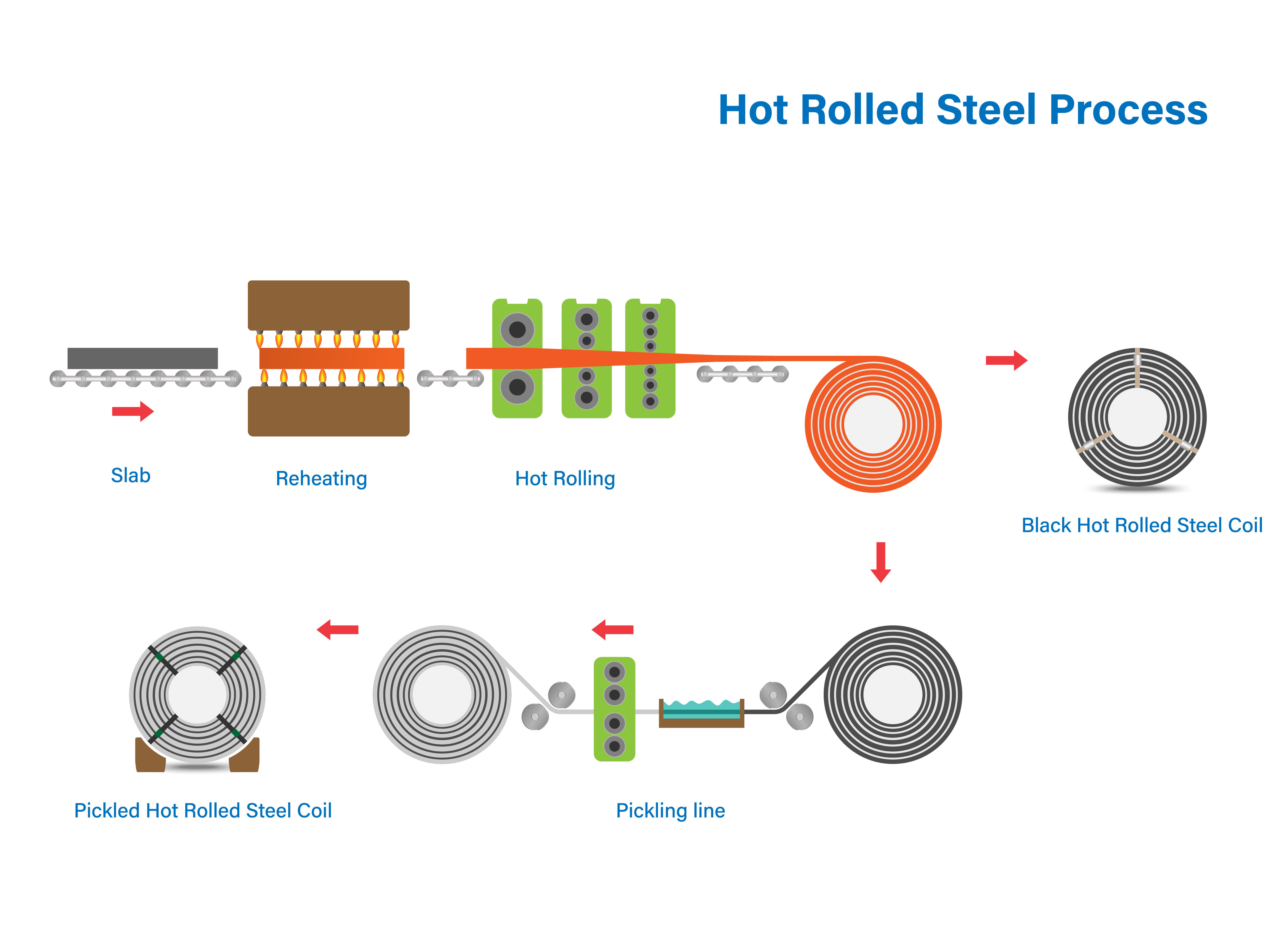

What is Hot Rolled Steel?

Hot rolled steel is a type of sheet formed by heating the steel to above the recrystallization temperature and then subjecting it to a series of rolling steps, followed by natural cooling.

Advantages of hot rolled steel

1. It can be produced in large sizes and in large quantities, with simpler processes and relatively cheaper prices.

2. It is more conducive to processing into various required shapes and has better molding effects

Disadvantages of hot rolled steel

1. The surface of the steel is rough after production and needs additional grinding.

2. The dimensional accuracy is lower than that of cold-rolled steel

3. Without anti-corrosion treatment, it is relatively easy to corrode

Wich roll forming machine can using hot rolled steel?

Roof tile making machine, purlin roll forming machine and drywall framing machine can using hot rolled steel to made.

What is Cold Rolled Steel?

Cold rolled steel is steel that has been rolled at room temperature, below its recrystallization temperature, to achieve a desired thickness and surface finish. This process results in a product with enhanced mechanical properties and a smoother surface compared to hot rolled steel.

Advantages of Cold rolled steel

Superior Surface Quality: Ideal for applications requiring a smooth and clean surface.

High Strength and Hardness: Enhanced mechanical properties due to work hardening.

Precision and Consistency: High dimensional accuracy and consistency.

Disadvantages of Cold rolled steel

Higher Cost: Generally more expensive than hot rolled steel due to additional processing steps.

Reduced Malleability: Less malleable compared to hot rolled steel, which can make it harder to work with in some forming processes.

What products are produced by cold roll forming machines using Cold Rolled Steel?

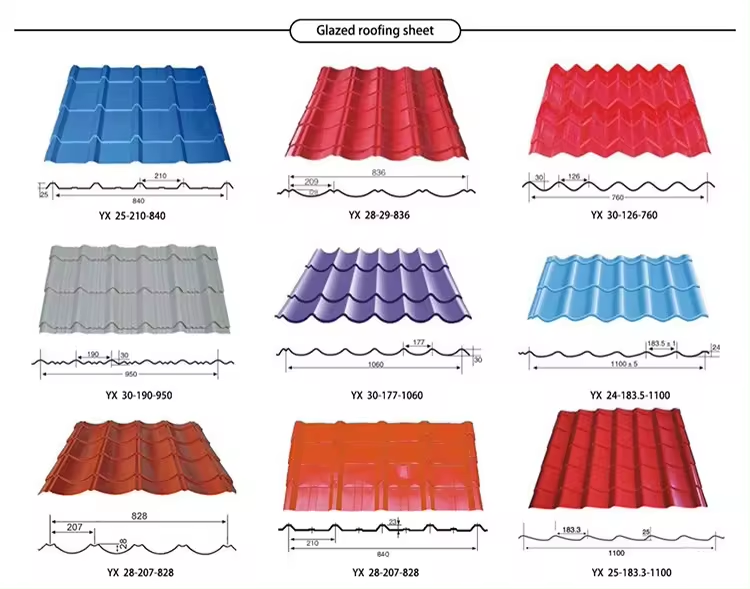

glazed steel tile and H purlin and some floor deck profile.

Impact of Differences on Roll Forming

Hot Rolled Steel

Easier to form, but the rough surface can cause wear on forming tools.

Variability in dimensions may necessitate more adjustments during forming.

Cold Rolled Steel

Requires more precise tooling and control due to higher strength and lower ductility.

The smooth surface reduces wear on tools and improves the quality of the final product.

Key Differences Between Hot Rolled Steel and Cold Rolled Steel

- Surface Finish

- Dimensional Tolerances

- Mechanical Properties

- Cost and Availability

- Applications and Suitability

Choosing the Right Type of Steel for Your Roll Forming Process

Selecting the right type of steel for your roll forming process is crucial for achieving optimal product quality, cost efficiency, and performance.

Balance the initial material costs with the benefits of reduced processing times and improved product quality when choosing between hot rolled and cold rolled steel.

Choosing the right type of steel for your roll forming process involves a thorough understanding of material properties, application requirements, and cost considerations, ensuring the selection of the most suitable material for high-quality, efficient production.