In the modern construction industry, innovative technologies are constantly evolving to address the increasing demands of the sector. Among these advancements, the Soffit Panel Roll Forming Machine has emerged as a key piece of production equipment gaining significant attention. This machine not only produces high-quality soffit panels with remarkable efficiency but also enhances overall production processes and reduces costs. In this article, we will explore the functionality, benefits, and applications of the Soffit Panel Roll Forming Machine within the construction industry, market, environmental conditions, and business goals

Demand for Soffit Panels in Ethiopia

Ethiopia has a diverse climate, including high temperatures, humidity, and rainfall. Therefore, the soffit panels need to have good corrosion resistance, water resistance, and UV resistance to ensure long-term use in various environments.

Due to the hot climate in some areas, the soffit panels may need to have certain insulation properties to help the building maintain a comfortable indoor temperature.

Consider Material Availability

Material Type: Steel, aluminum or other alloy materials are commonly used soffit plate materials. Choose the type of material that is suitable for the Ethiopian market and ensure that it performs well in terms of lifespan, maintenance cost and sustainability.

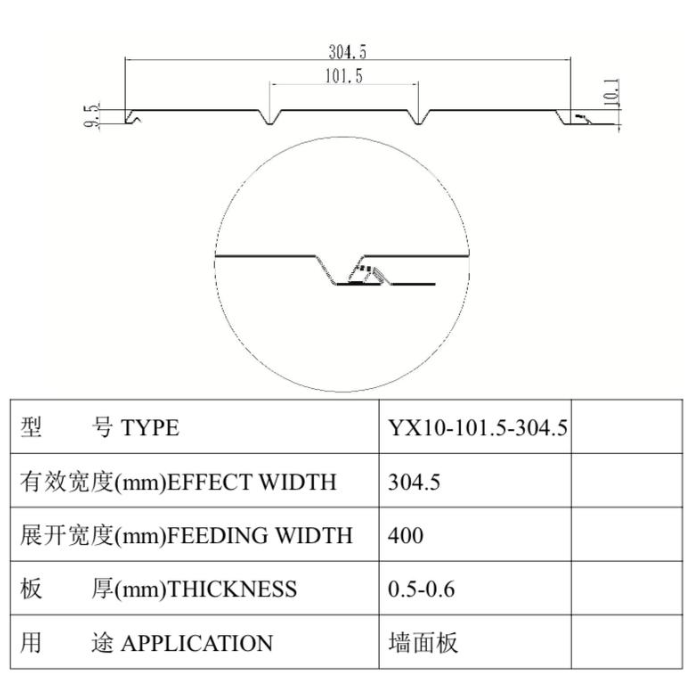

Soffit board pattern diagram

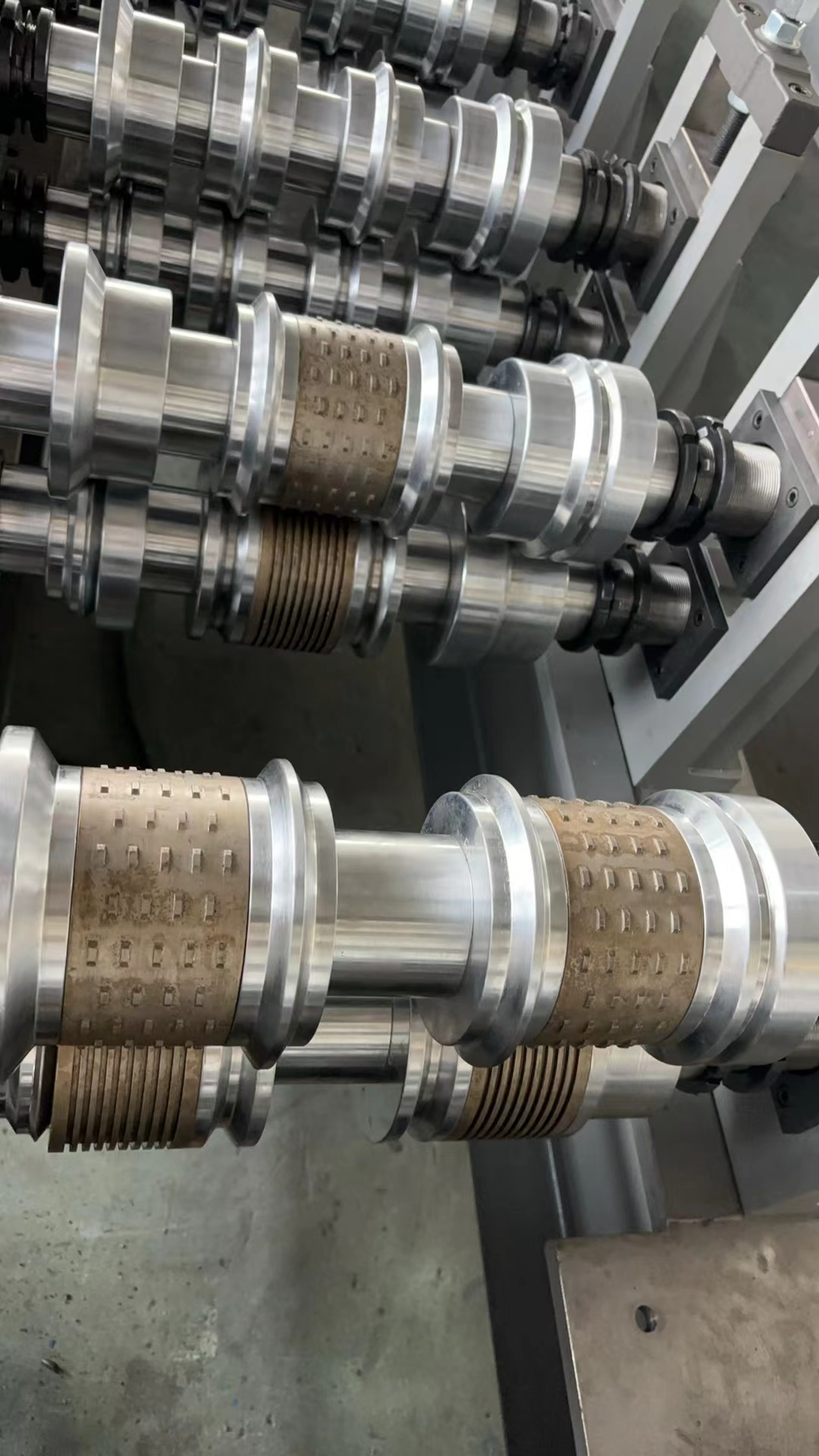

How the Soffit Panel Roll Forming Machine Operates

The Soffit Panel Roll Forming Machine is an automated system that converts coil stock into soffit panels through a continuous roll forming process. This process involves several stages, including coil unwinding, forming, cutting, bending, and stacking. As the coil stock passes through a sequence of pre-configured rollers, it gradually takes on the desired shape, transforming into the final soffit panel. The design and arrangement of these rollers are crucial in shaping the material accurately. The entire operation is highly automated, ensuring speed and efficiency, making it ideal for large-scale production.

Advantages of the Soffit Panel Roll Forming Machine

- High-Efficiency Production: Leveraging the continuous roll forming technique, the Soffit Panel Roll Forming Machine operates at high speeds, making it well-suited for large-scale production. This significantly enhances production efficiency.

- Precision Forming: The machine ensures precise dimensions and smooth surfaces for soffit panels by meticulously controlling the shape and arrangement of the rollers, meeting the construction industry’s stringent accuracy standards.

- Cost Reduction: Automation reduces the need for manual intervention, thereby lowering labor costs. Additionally, the continuous roll forming process minimizes material waste, contributing to overall cost savings in production.

- Customized Production: The Soffit Panel Roll Forming Machine can be adjusted to produce soffit panels in various sizes and shapes, allowing it to meet the diverse and customized demands of the construction industry.

Applications of the Soffit Panel Roll Forming Machine in the Construction Industry

Soffit panels produced by the Soffit Panel Roll Forming Machine are extensively utilized in various construction projects, including residential, commercial, and industrial buildings. These panels are primarily installed in ventilation openings, beneath roof eaves, and other areas where they provide essential functions such as ventilation, dust protection, and insect prevention. Additionally, they contribute to the aesthetic appeal of buildings. The introduction of the Soffit Panel Roll Forming Machine has significantly boosted the efficiency and quality of soffit panel production, offering a more effective, precise, and cost-efficient solution for the construction industry.

Summary:

As an innovative technology in the construction industry, the Soffit Panel Roll Forming Machine not only improves the efficiency and quality of soffit panel production but also reduces costs while meeting the industry’s stringent precision requirements. With the ongoing growth of the construction sector, the applications and benefits of the Soffit Panel Roll Forming Machine are expected to expand even further.