Introduction

Traditional step tile roof panel machines have a very slow speed of only 0-4m/min because there are many steps on the panels. However, a higher production speed allows workers to complete production tasks more quickly and reduce labor costs accordingly. In response to this problem, our company has also invested a lot of time and energy to improve it, and finally reached 4-6m/min.

Factors affecting production speed

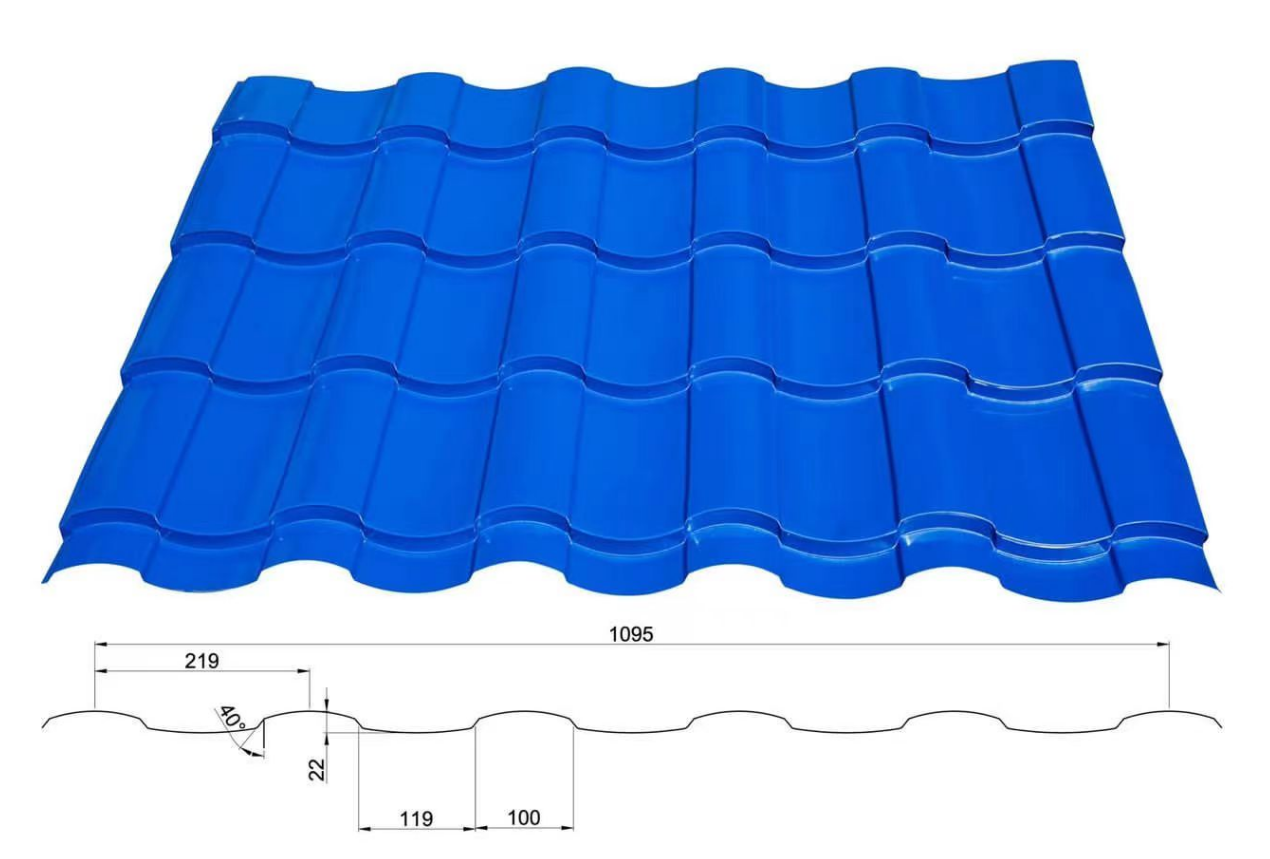

To understand the factors that affect the production speed of roof tiles, we must first know the structure of the roofing making machine.

The main parts of the roofing tile machine are

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

The main factor affecting the production speed is the main roll forming, which includes the PLC control system, motor, transmission chain, and cutting device.

How to improve the configuration of roof tile machine

First , drive motor we use servo motor instead of traditional motor, after machine do step every time, roll forming machine start and stop speed is more fast, thus improve whole production speed.

Second, transmission we use gear box instead of chains, provide more power , also improve production speed.

Roll forming machine speed improved, how to ensure step mechnism and cutting device power provided continuously?

We adopt accumulator installed on hydraulic station, also increase hydraulic pump motor power to be 7.5kw. Thus ensure enough and continuous power provided to step mechnism and cutting device.

For Adamante profile roll forming machine, we also have a special design, that is the automatic stacker.

This design is convenient and good use to collect sheet.