C stud partition drywall keel steel and hat profile ceiling steel are essential components in the construction and decoration industry. C stud partition keel steel is commonly used to create partition systems, while hat profile ceiling steel is crucial for installing suspended ceilings.

Introduction to C Stud Drywall Keel Steel and Hat Profile Ceiling Steel

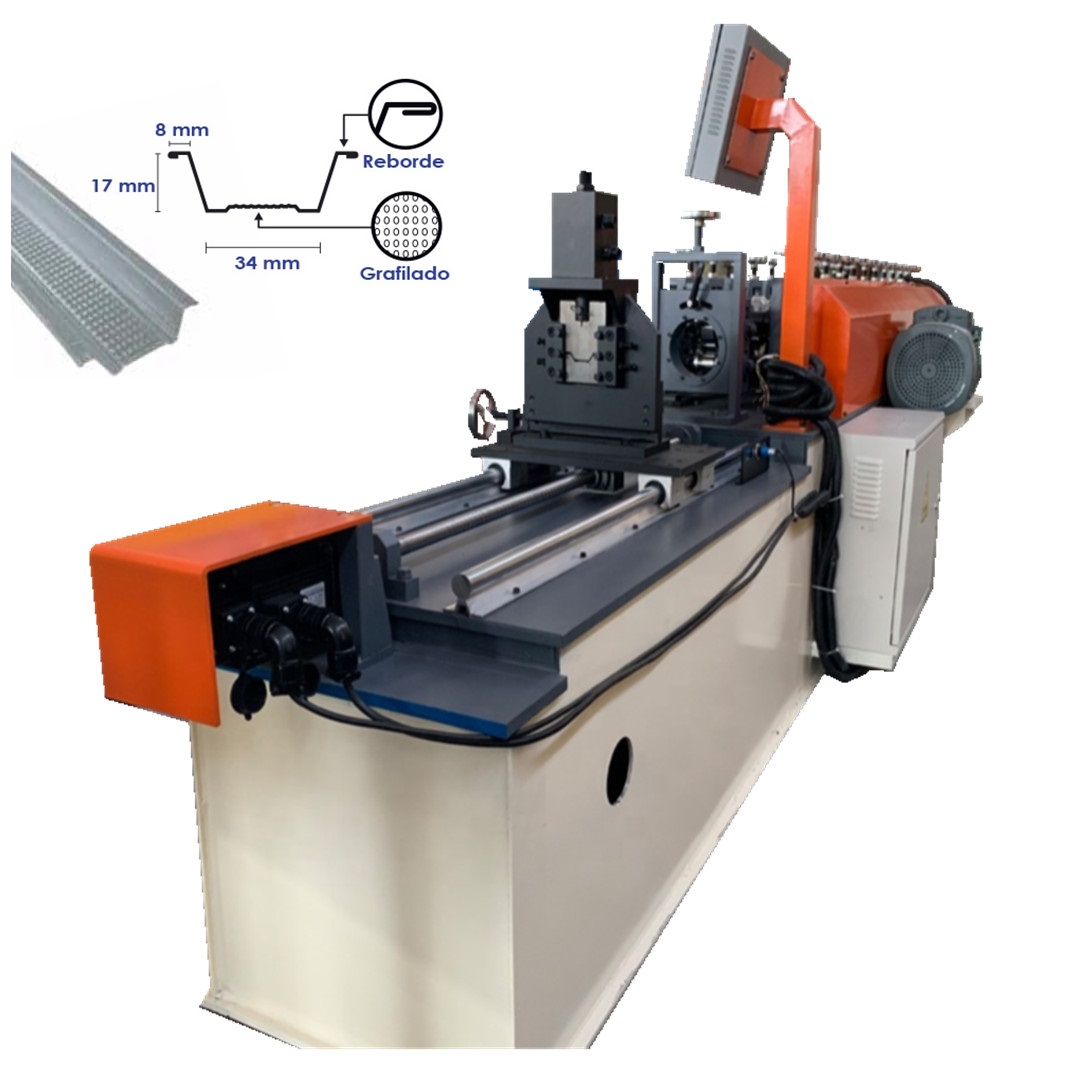

C steel stud machineDrywall Keel Steel

Shape: Typically “C” shaped.

Material: Commonly made from galvanized steel.

Function: Serves as the main support structure for partition wall systems, providing strength and stability.

Installation: Usually fixed on the ground and top using expansion screws, followed by the installation of the partition plate.

Hat Profile Ceiling Steel (also known as Omega Ceiling Steel Profile)

Material: Galvanized steel.

Function: Acts as the skeleton of the ceiling system, supporting the ceiling plate.

Installation: Installed on the main keel and connected by bolts to form a stable ceiling structure.

In construction and decoration projects, C stud metal steel and Omega profile steel are indispensable components. They provide essential structural support and simplify the construction process due to their standardized dimensions and ease of installation. The efficiency and flexibility of the cold forming machine are crucial to meet the market demand for these components.

Combining Two Roll Forming Machines into One

Challenges

Normally, producing C stud metal steel and Omega profile steel requires two separate roll forming machines. This can be a challenge for customers with limited space.

Solution

To address this, we combine two machines into one double unit, known as a double line roll forming machine. This innovative solution features two lines with independent control systems and forming molds, allowing both production lines to work simultaneously or independently, saving space and reducing costs.

Benefits

Space Saving: By combining two machines into one, the double line roll forming machine occupies less floor space.

Cost Efficiency: Shared components and systems reduce overall costs.

Operational Flexibility: The ability to run both lines simultaneously or independently enhances production flexibility.

Stable Performance: Ensures high efficiency and customer satisfaction.

Setting Up the Double Line Roll Forming Machine

we combine 2 separate machines together to form a double unit, we call it double line roll forming machine.

2 lines with 2 independent control systems and forming molds, 2 production lines can work at the same time.

Also 1 production line can work. The other one stop.

This not only saves space, but also saves some costs, metal steel C stud Omega profile double line forming machine working performance is stable, efficient, customers are very satisfied.

The details are shown in the following figure