The procedure that should be video and photo:

1. Video. General view of the line and all units included in the delivery set.

2. Video. Measure the thickness of the raw material metal (roll metal) with a micrometer.

3. Video. Production of profile No. 1, in the amount of 10 pieces, the profile length is 3 meters, shoot so that it is powerful to calculate the productivity of 50-60 m / min. The view should be from the guillotine side, so that you can see how the guillotine cuts. Next, without interrupting the video shooting, measure the length of the profile and make a video of the profile from different sides.

4. Video of checking the straightness of the profile:

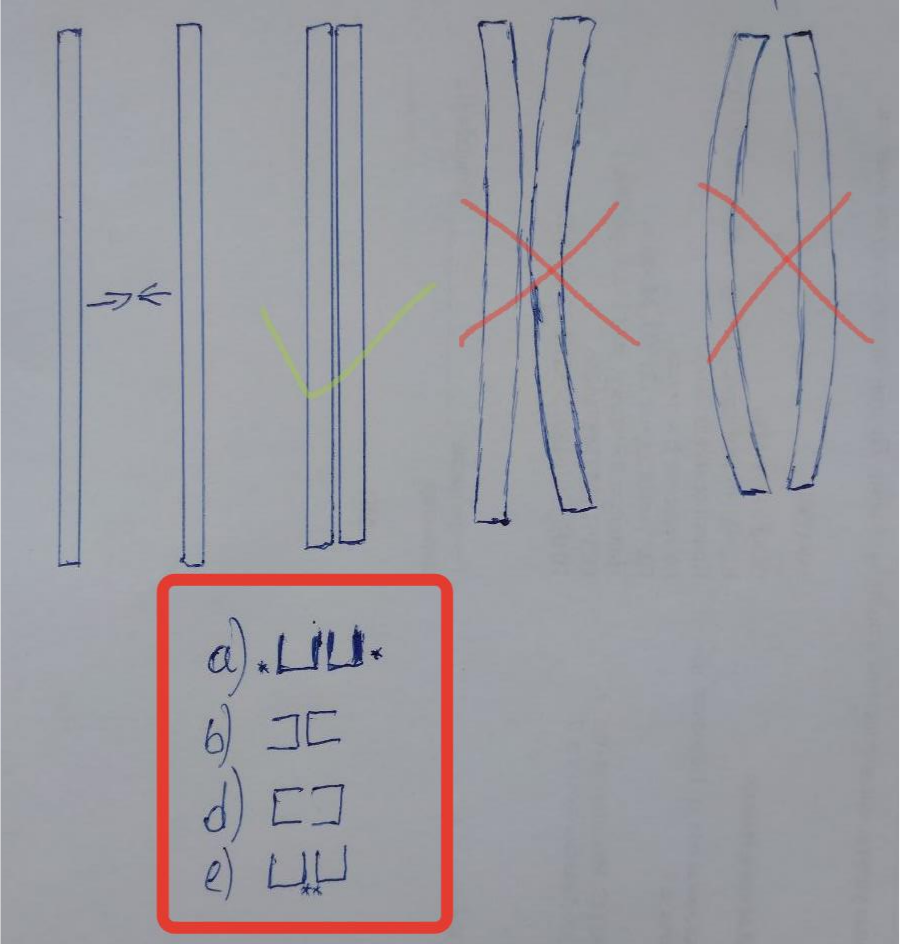

Take the profile, 2 pieces, and put them next to each other tightly, as shown in the figure below.

IMPORTANT: The profiles cannot be turned over, they must be folded exactly as they came out of the machine.

Take photos and videos of the profiles in all four positions: a, b, d, e.

5. Check the quality of the cut, there should be no burrs that could be felt on the fingers. Take several photos of the profile from the end.

6. Video. Show the Russian interface in the control panel.

7. Take a photo of the control cabinet inside.

8. Take a photo of the rolling mill motor and guillotine so that the tag with the motor power is visible.

9. Take photos of the hydraulic station from different sides.

10. Video. Retooling the machine for profile #2. Show how the cassette is changed, how the guillotine knives are changed. Do I need to change anything in the control panel?

11. Repeat all points 2-5 for profile #2.

12. Make a video of the documentation that comes with the machine.