What is a roof drip edge?

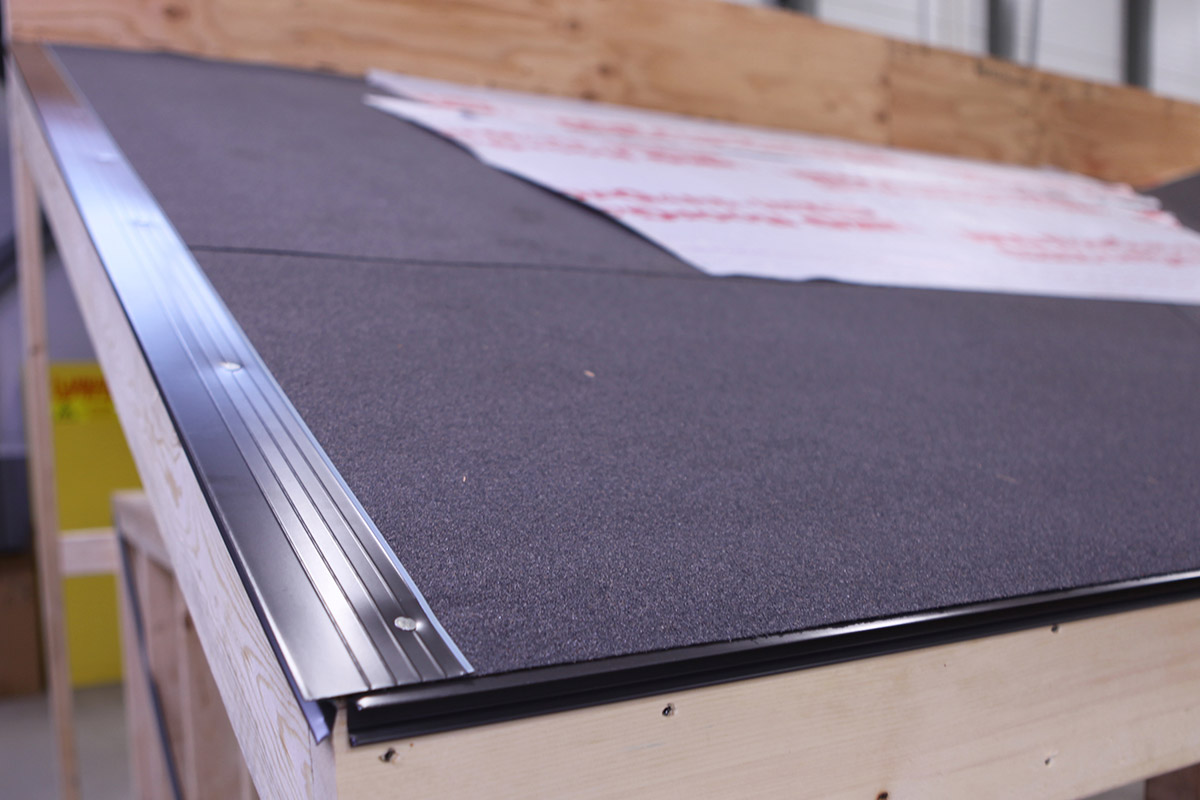

A drip edge is a metal sheet installed at the edge of a roof, usually in an “L” shape, also known as flashing or “D-type” metal. Its main function is to guide water from the eaves to the gutter to prevent water from flowing under the roof tiles, thereby protecting the structure of the house from water damage. Although some older buildings may not have drip edges installed, most building codes in North America now require them to be installed to more effectively protect the house.

The role of a roof drip edge

The drip edge on the roof has the following two main functions:

Direct water flow and protect the eaves: Due to the cohesion and surface tension of water droplets, water tends to adhere and spread along the surface. The design of the drip edge can guide these water droplets and use gravity to direct water into the gutter. If there is no gutter, the drip edge can prevent water from flowing down the eaves or seeping into the eaves structure; if there is no drip edge, water may be trapped on the tiles and then seep into the roof, causing roof leaks and eaves rot.

Protect against wind and rain: In severe weather, wind may blow rain onto the roof. While roof tiles, waterproofing underlayment, and ice protection protect your roof, a drip edge must be windproof and waterproof at the edges. The drip edge is constructed to catch wind-blown water and prevent it from blowing under the tiles. Without a drip edge, the roof is more susceptible to wind and rain damage.

Types of Drip Edge Materials

Drip edges are typically made of corrosion-resistant or galvanized metal to comply with most building codes. Common materials include:

Aluminum: One of the most common drip edge materials, aluminum is corrosion-resistant and easy to match with the house, but it is softer than steel.

Galvanized Steel: Steel drip edges must be galvanized to prevent rust. It is recommended to use at least 24-gauge steel to ensure that it can withstand strong winds.

Copper: Copper drip edges are beautiful and durable, and they give the roof a unique look. Copper should be 0.69 mm or 20 ounces thick.

Plastic, vinyl, and fiberglass drip edges are also available on the market, but these materials are generally more suitable for use above doors and windows rather than roofs.

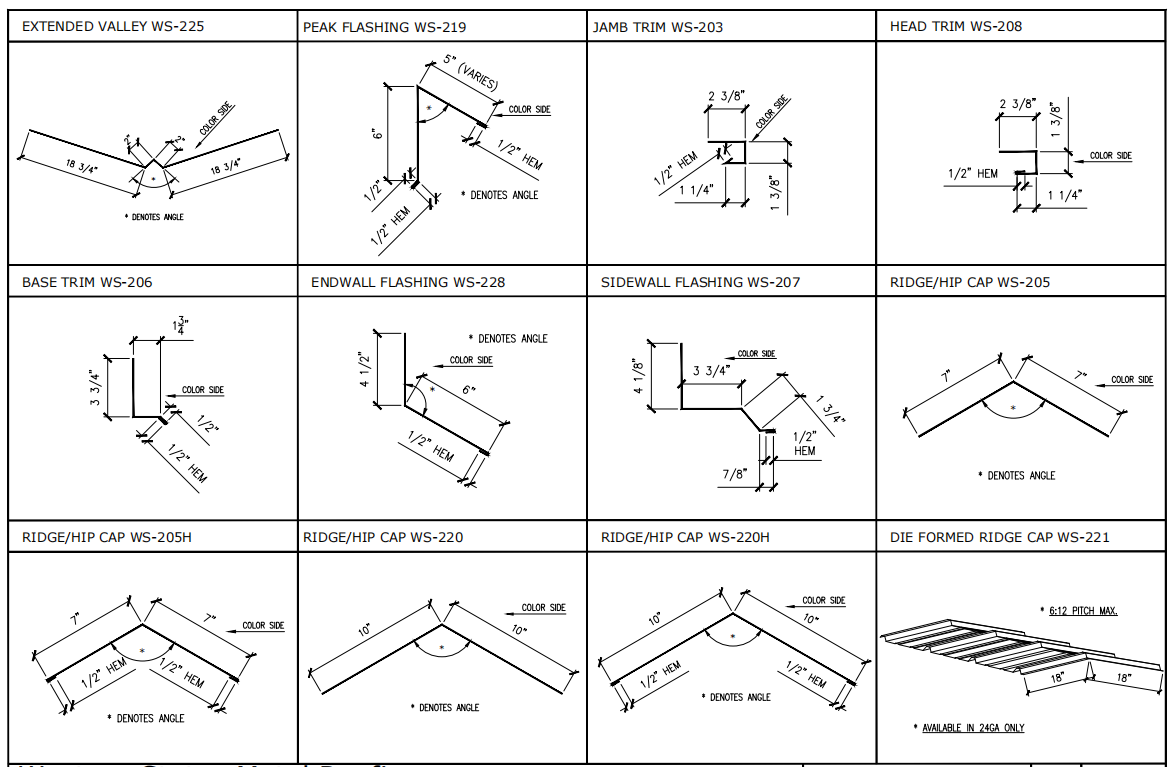

Drip Edge Profile Types

Drip edges generally come in three basic shapes, each of which may have multiple names:

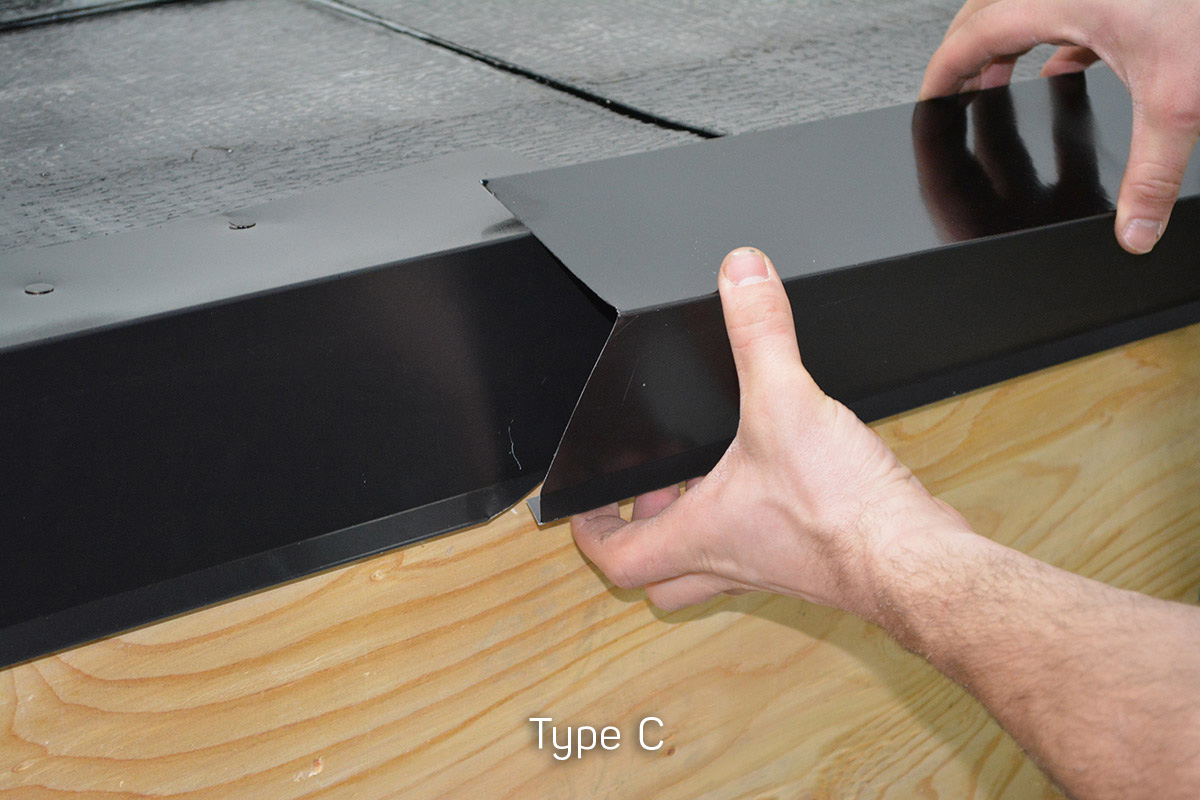

C-shaped: The classic “L”-shaped drip edge, also called an “L-shaped,” is angled at 90 degrees with a lower flange.

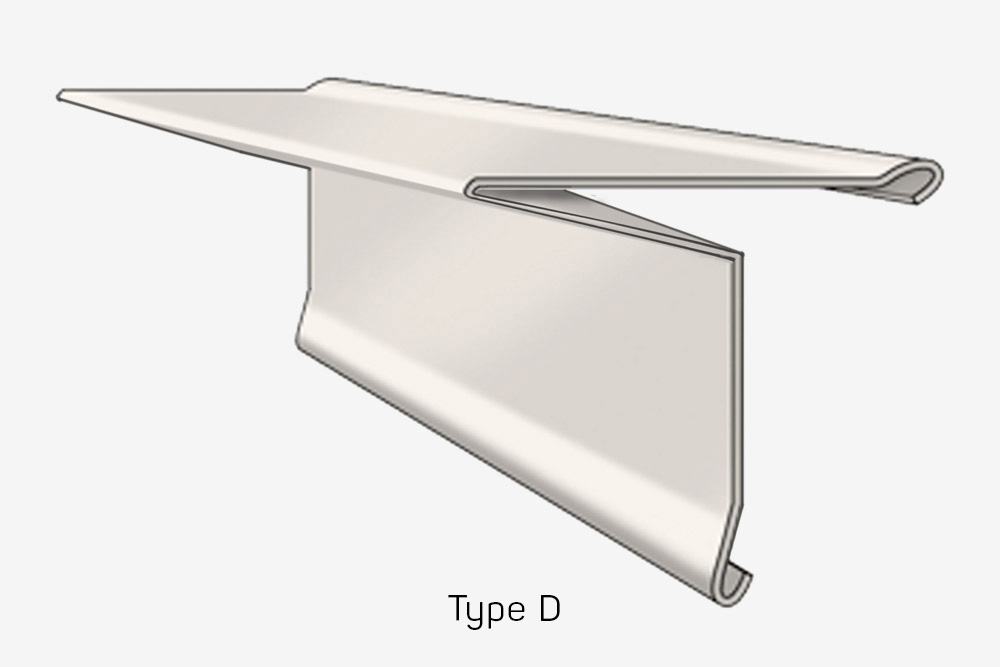

D-shaped: This shape resembles a “T,” also called drip edge metal or a “T-shaped.” This design directs water away from the fascia more effectively than the C-shaped design, meeting the recommendations of the Asphalt Roofing Manufacturers Association.

F-shaped: This extended drip edge has a longer leading edge and is suitable for adding a new drip edge to an existing shingle or bevel edge. It is often called a “gutter apron.”

What if you need to replace the drip edge on an existing roof or install a drip edge on an existing roof for the first time? It can be done; here’s how:

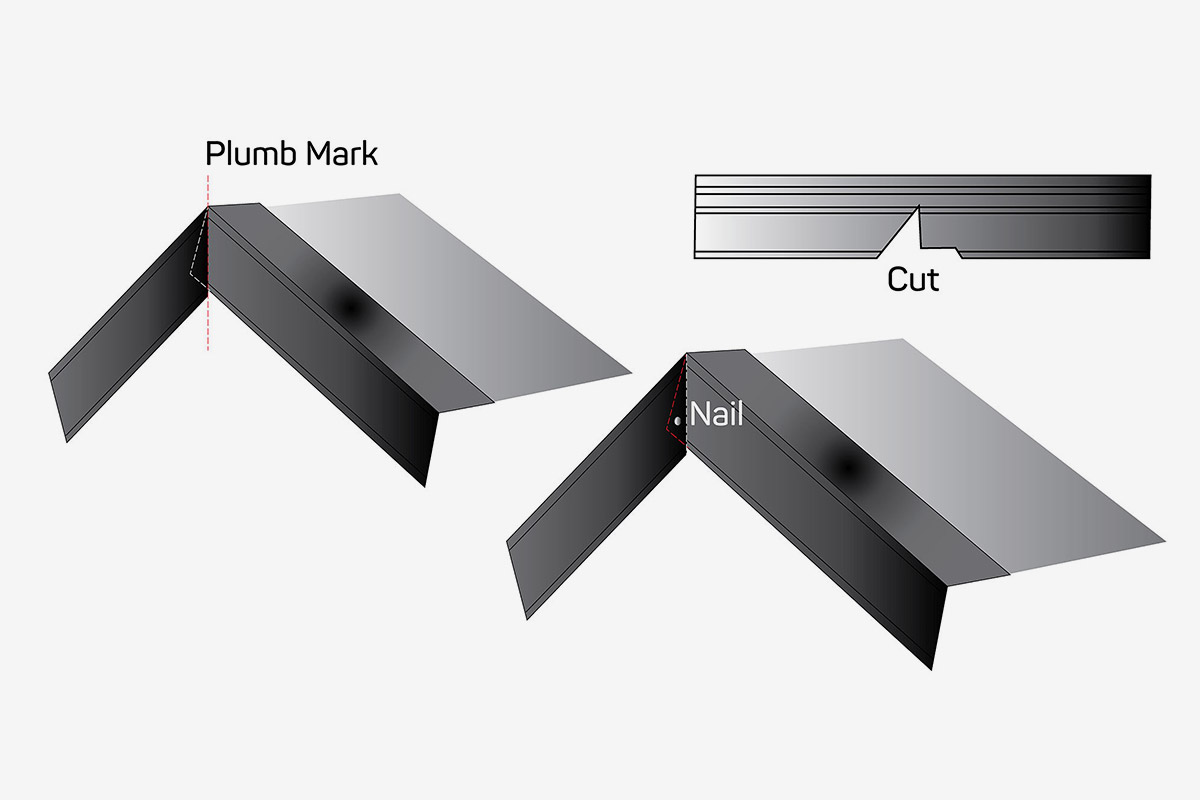

- Step One :Gently lift up the shingles on the edge of the roof and locate the nails holding the existing drip edge onto the roof.

- Step Two :Use a flat pry bar and hammer to pry the nails out of the drip edge gently.

- Step Three :Once free, slide the drip edge out and discard.

- Step Four :Install the new drip edge as described above, with cement and nails. You’ll need to ask another roofing professional to hold up the shingles while you do so.

Just as with installing drip edges on new roofs, you should check with your local building codes to see if there are special rules you have to follow about drip edge replacement.

In years past, many building codes did not require drip edges; but the roofing community realized that these relatively inexpensive products make a big difference in the performance of the roof. By installing drip edges properly, you’ll be giving your customers a better roofing system.

If you’ve discovered your roof is missing a drip edge, or has a damaged drip edge, you can get in touch with a roofing contractor through our Roofing Contractor Locator ZTRFM to get professional advice.

The video below provides additional information on drip edge installation on shingle roofs:

We also can provide Drip Edge roll forming machine