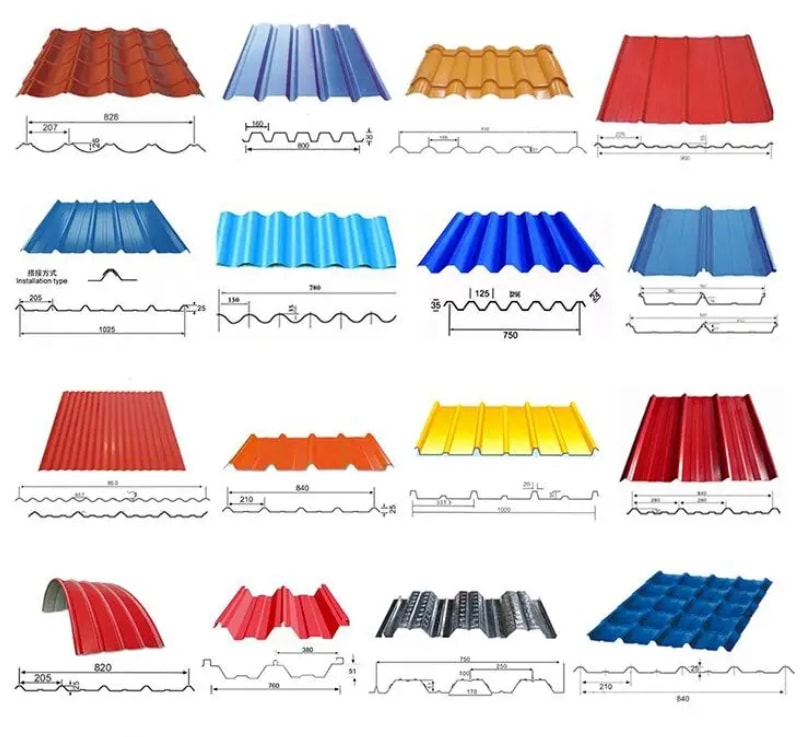

Our Laminated R Panel Terrazzo PE Foam Metal Steel Roofing Sheet Composite Thermal Insulation Tiles Making Roll Forming Machine for different models based on different designs or customer’s samples . It is a machine produce building material of metal roof, the products are widely used as the roof and wall of factory,warehouse, garage, gymnasium, exhibition center.It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

|

Laminated R Panel Terrazzo PE Foam Metal Steel Roofing Sheet Composite Thermal Insulation Tiles Making Roll Forming Machine

|

||||

|

1.Formed Material

|

PPGI,GI,AI and ZTRFM new design composite material

|

Thickness:0.3-1.0mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

20 rows(Due to your profile drawing design)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

18T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-80m/min

|

The speed is adjustable

|

||

Machine Advantage:

Suit for normal PPGI metal steel materials also our brand mini laminated composite material.This laminated composite material can laminated different layers and materials,with different function.Here laminated PE poam roof sheet showing for you.

Why produce this roof sheet?