Recently, our company successfully reached a cooperation with a Peruvian customer, who ordered a high-performance TR4 roll forming machine.

When visiting our production workshop, the customer gave high praise to the following aspects:

Advanced production line: The manufacturing process of the equipment demonstrates our strict control of details and high standards for quality.

Technical strength: The customer fully recognized the core technical features of the TR4 roll forming machine, including its high-precision forming, stable operating performance and efficient production capacity.

Service professionalism: From technical questions to customized solution design, our team demonstrated a professional and meticulous service attitude to relieve customers’ doubts.

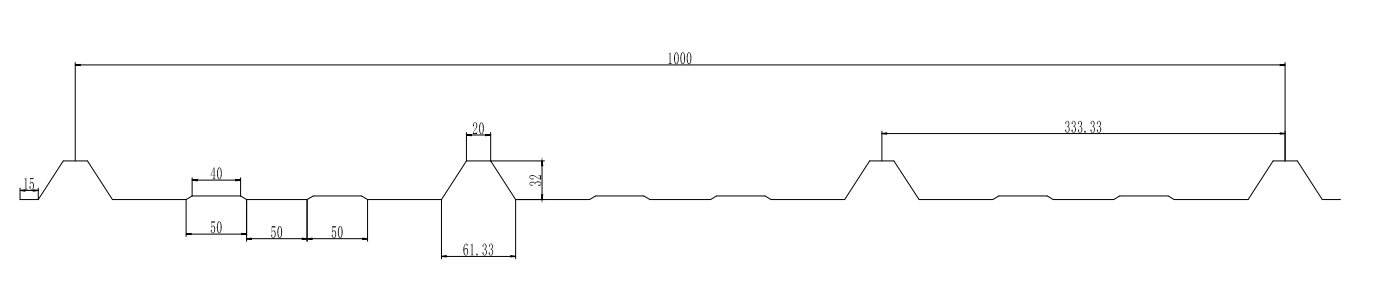

1.One machine can produceTR4 sheet

2.Coil width is 1220mm

3.The voltage of this machine is 380V,50HZ,3P,not same as normal Peru customer!

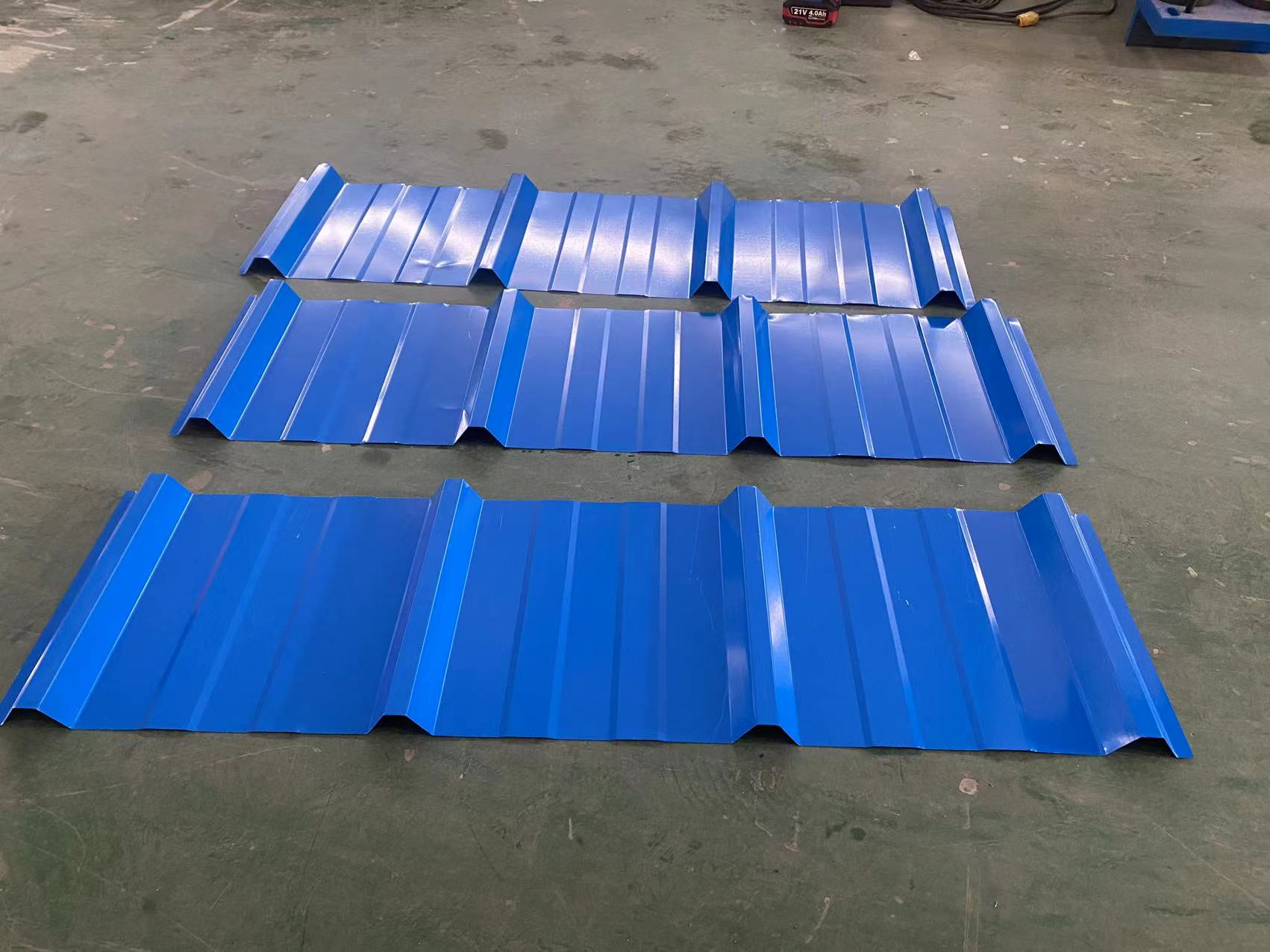

The pictures for the finished product:

The profile drawings:

The components of the machine:

| No. | Name | Quantity |

| 1 | Manual Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | PLC Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the machine:

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.28-0.4mm(thickness range shouldn’t be too big) |

| 3 | Decoiler | 5T manual decoiler |

| 4 | Roller station | 14 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 13 | Cutting blade material | Cr12 with quenched treatment |

| 14 | Cutting tolerance | +/-1mm |

| 15 | Control system | PLC |

| 16 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Key Features of Our Machine

- Decoiler

- Available in both manual and hydraulic options to suit different budgets and production needs.

- Roll Forming Machine

- Machine Frame: Constructed from 350# H steel with a central beam support for enhanced stability.

- Transmission: Double-chain transmission ensures smooth and reliable operation.

- Shaft Diameter: 80mm solid shafts for durability and high performance.

- Roller Material: High-grade 45# steel with a chrome-plated surface for improved hardness and wear resistance.

- Double-Layer Machine: Equipped with a clutch device that allows independent operation of the upper and lower layers. This feature minimizes roller wear and extends the machine’s lifespan.

- Cutter

- Designed with a robust 4-pillar cutter frame for stability.

- The cutting mold is made of Cr12MoV steel with quenched treatment, ensuring high cutting precision and durability.

- Control System

- Uses renowned brands like Delta, Siemens, Omron, Schneider, and Mitsubishi.

- Customizable to incorporate customer-preferred brands for seamless integration.

- Hydraulic System

- All hydraulic stations are equipped with fan cooling systems, effectively reducing coil temperatures during prolonged use or operation in hot climates.