A Portable & Movable Standing Seam Forming Machine is a specialized roll-forming machine designed to produce standing seam metal panels used for roofing. The key feature of these machines is their portability, allowing them to be transported easily to different job sites, making them highly efficient for on-site roofing panel production.

The machine produces panels for standing seam roof with a double seam. The machine works with all types of roof covering: steel (including polymer-coated), copper (including painted), aluminum, zinc, aluzinc, zinc-titanium. The material may

be in rolls or in sheets. Optimized configuration of grading rollers ensures high quality of the profile.

Key Features:

These machines are typically mounted on wheels or trailers, allowing them to be moved easily to different locations.

They are compact and lightweight compared to traditional roll-forming equipment.

Standing Seam Panel Production:

The machine forms metal sheets into standing seam panels, which are commonly used in roofing systems.

Standing seam panels feature raised seams (or “ribs”) that interlock, providing weather-tight roofing.

Material Compatibility:

Works with various metals such as aluminum, steel, copper, and zinc.

Capable of forming panels from different thicknesses depending on the machine’s specifications.

Customization:

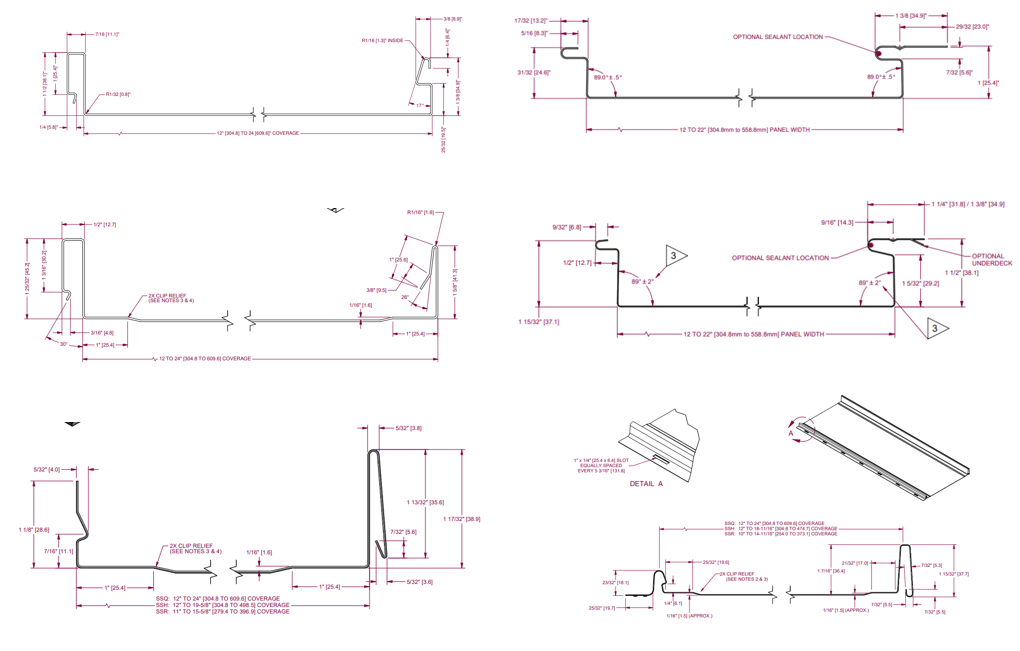

Some models allow for customization of panel width and seam height to meet specific project requirements.

On-Site Efficiency:

By producing panels directly on-site, the need for transportation of pre-fabricated panels is reduced, cutting down costs and time.

This also ensures that panels are cut to exact lengths, reducing waste.

Typical Uses:

Commercial and Residential Roofing: Often used in metal roofing projects where standing seam panels provide durable, long-lasting, and aesthetically appealing solutions.

Construction Sites: Portability makes it suitable for construction sites where customized roofing panels are needed quickly and on-demand.

This equipment is favored by contractors and builders looking for efficiency and flexibility in metal roofing projects.

Distinctive feature of the machine: Quick infinitely variable width of the work piece width in the range 320-625 mm. By rotating the handle with two screw pairs

synchronously moving carriages moving the profiling rollers. Suitable for use both in the workshop and on site;

Manufactures roofing panel-painting line and trapezoidal shape, as well as a one-way seam;

High quality of products through the use of an optimized design;

The use of complex composite rollers completely eliminates damage to the polymer coating of metal;

Matching the Material:Color coat plate, galvanized plate

Roller station:5 rows

Specification:560mm*350mm*480mm

Weight:around 35 kg

Material thickness:0.3-0.8MM

Motor power:2.4KW

speed:30 m/min

Base: Casting Aluminum, Cover: Aluminum, Ape: A Cape Tube, Spindle: 40Cr Modulation, Rollers: 40CR Heat Treatment, Caste: Nylon Material, Screw: 8.8 League Black

Voltage: 220V single Phase

More standing seam pattern pictures:

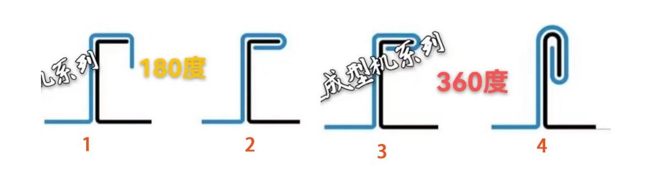

There are two types of mechanical locking methods: single locking and double locking. Single locking is easier to disassemble and replace, and double locking is more tightly locked.

Single locking and double locking have nothing to do with the molding machine, but are related to the locking machine:

As shown below:

This is the entire process of a normal locking machine with double locking, with a total of four steps. If the third and fourth steps are removed, leaving only the first and second steps, then the locking machine completes the single locking. The locking machine shares 5 rows of rollers. The first and second rows of rollers control the single locking, and the last three rows complete the double locking.