The downpipe roll forming machine also called downspout roll forming machine. The downpipe use for guiding the rain water down, usually thickness 0.3-0.8 mm with color coated galvanized steel material. Machine speed about 0-15 m/min. PLC system can control the machine speed, quantity and downpipe length.

To ensure the downpipe roll forming effect, we add mandril in it, when roll forming, the material will be around it, after produced, the body will not deform and will not have burr.

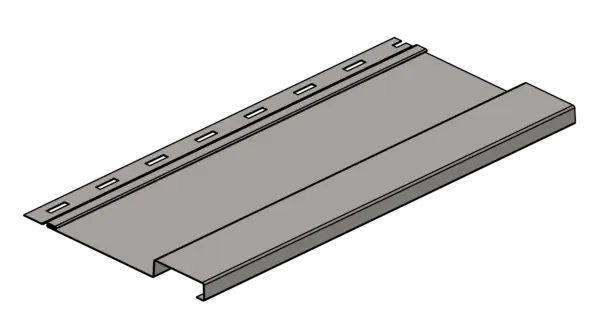

Here introduce the downpipe profile drawing to you:

Main technical parameters of downpipe roll forming machine:

| Series | Detail | Parameter |

| Decoiler | loading capacity | 3 Tons |

| Inner diameter | 450-550 mm | |

| Coil width | 400 mm | |

| Main roll former | roller material | 45# steel with chromed treatment |

| roller shaft material | 45# steel with quenched treatment | |

| work speed | 8-15 m/min | |

| machine structure | Middle plate welded structure frame | |

| work power | 4 kw | |

| PLC control system | PLC brand | DElTA brand (also can change by your request) |

| function | Control the length and cutting quantity | |

| Cutting system | cutting type | Fly saw or hydraulic cutting |

| motor power | 3 kw | |

| Run out table | structure | Square pipe welded structure |