Introduction

The Slotted Deflection Track Rolling Forming Machine is an advanced piece of equipment designed for the precise manufacturing of slotted deflection tracks, essential in modern construction for managing structural movement and stress.

Dry Wall Partition System Components

Dry Wall Angle

Track

Stud

Gypsum Board

Steel Stud Drywall Framing System

The Steel Stud Drywall Framing System offers a durable, practical, and lightweight structure suitable for internal plasterboard walls and specific external walls.

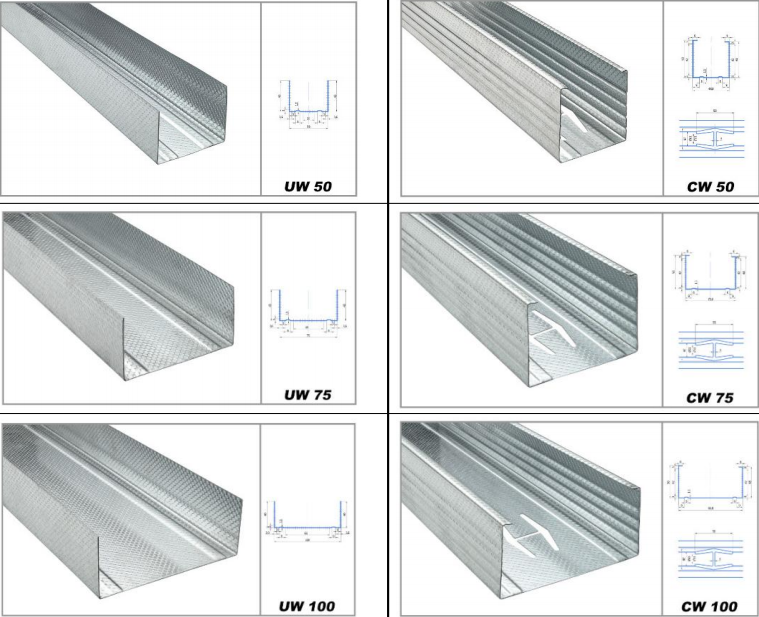

Metal Profile Stud & Track for Partition System

This system is made from hot galvanized steel and includes Stud, Track, C-Channel, Corner bead, and accessories. The components are designed to provide a robust and efficient framing solution for drywall partitions.

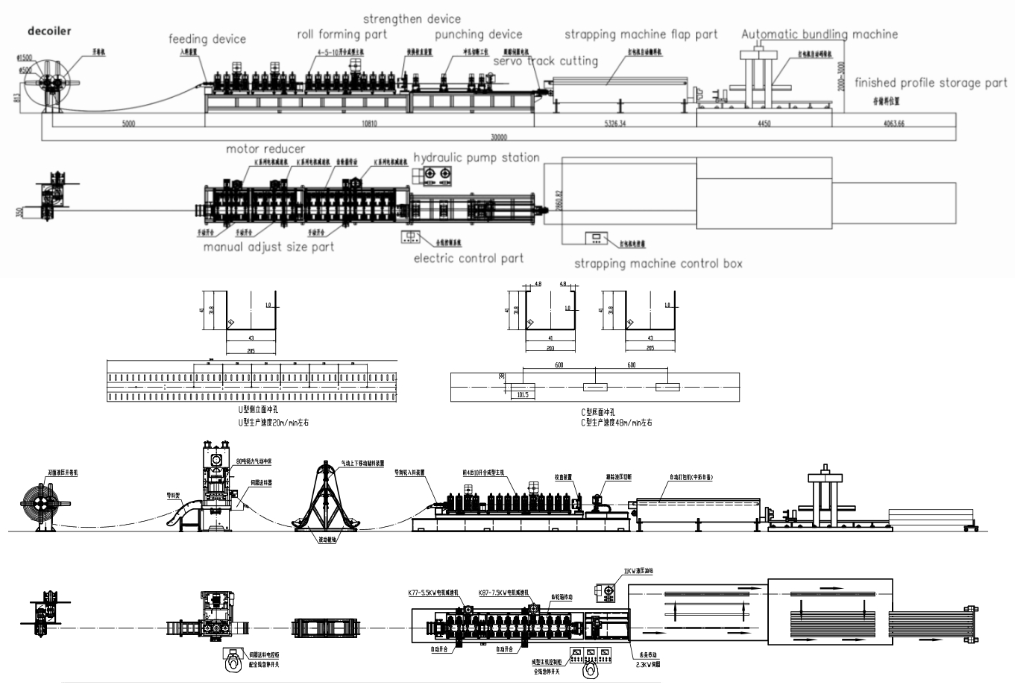

CW UW Frame Roll Forming Machine

The CW UW frame roll forming machine features a CNC controlling system, enabling fully automatic operation. This advanced system ensures precise and efficient production of steel framing components.

High-Speed Cutting Device

The machine incorporates a servo motor high-speed cutting system, which ensures precise and rapid cutting of steel components. This feature is essential for maintaining high production efficiency and quality.

Here is one drawing profile and finished product:

Select your product below:

Advantage of Slotted Deflection Track Rolling Forming Machine

1.For superior control of head-of-wall lateral deflection and axial rotation, ZTRFM’s Rapid Track slotted deflection track offers a dynamic solution for both interior and exterior walls that require heavy weight loading or are subjected to dynamic wind loads.

2.Rapid Track enables the top of the steel stud wall to float within the track legs, allowing vertical live load movement of the primary structure without transferring axial loads to the wall studs. This feature is crucial for maintaining the integrity and stability of the wall under varying load conditions.

3.In addition to vertical movement, Rapid Track includes slots that allow for horizontal drift when required by seismic designs. This flexibility ensures that the structure can withstand seismic activity without compromising the wall’s structural integrity.

4.Rapid Track is available in 3000mm leg lengths and a variety of track widths ranging from 64mm to 150mm. Its design facilitates easy installation, significantly reducing the cost of materials and labor. This versatility and ease of use make Rapid Track an ideal choice for a wide range of construction projects.

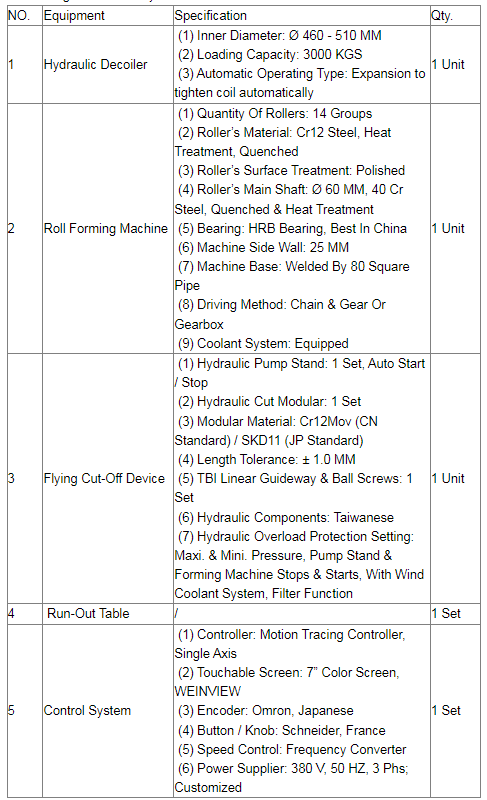

High Speed Automatic Slotted Deflection Track Rolling Forming Machine Specifications:

With auto packing and stacking system, full process working automatically

Can produce profiles between 2½”, 3 5/8″, 4″, 6″, 8″,10″

Flying shear and fly punching

Embossing – stamping

Safety cover

Siemens control system

Size change automatically

Key Features of the Slotted Deflection Track Roll Forming Machine:

Advanced Roll Forming Technology:The machine utilizes cutting-edge roll forming technology to shape flat metal strips into precise slotted deflection tracks. This process involves passing the material through a series of rollers that gradually bend and form it into the desired profile.

Material Versatility:Designed to work with various metals, including galvanized steel, aluminum, and other alloys, the machine provides flexibility in manufacturing tracks suitable for different construction requirements.

Precision Slotting Mechanism:The machine is equipped with a precision slotting mechanism that accurately punches slots into the deflection tracks. These slots are essential for allowing the tracks to accommodate movements and stresses without compromising the structural integrity.

Customizable Profiles:The machine offers the ability to customize the profile dimensions and slot configurations based on specific project requirements. This customization ensures that the produced tracks meet the precise needs of different construction applications.

High Production Speed:The Slotted Deflection Track Roll Forming Machine is designed for high-speed production, enabling manufacturers to produce large quantities of tracks efficiently. This capability is crucial for meeting tight project deadlines and high demand.

Automated Operation:Automation features, including computerized controls and programmable settings, enhance the machine’s operational efficiency. Automated operation reduces the need for manual intervention and minimizes the risk of errors.

Integrated Cutting System:An integrated cutting system ensures that the finished tracks are cut to the desired lengths with precision. This system synchronizes with the roll forming and slotting processes to maintain a continuous production flow.

Robust Construction:Built with durability in mind, the machine’s robust construction ensures long-term reliability and minimal maintenance requirements. High-quality components and materials enhance the machine’s lifespan and performance.