What is Slotted Stud And Track Roll Forming Machine?

A Slotted Stud and Track Roll Forming Machine is a specialized piece of equipment used in the construction industry to manufacture slotted studs and tracks. These components are essential in the construction of drywall partitions, suspended ceilings, and other structural applications. The machine’s primary function is to transform flat metal sheets into precise, slotted profiles through a series of forming and cutting processes.

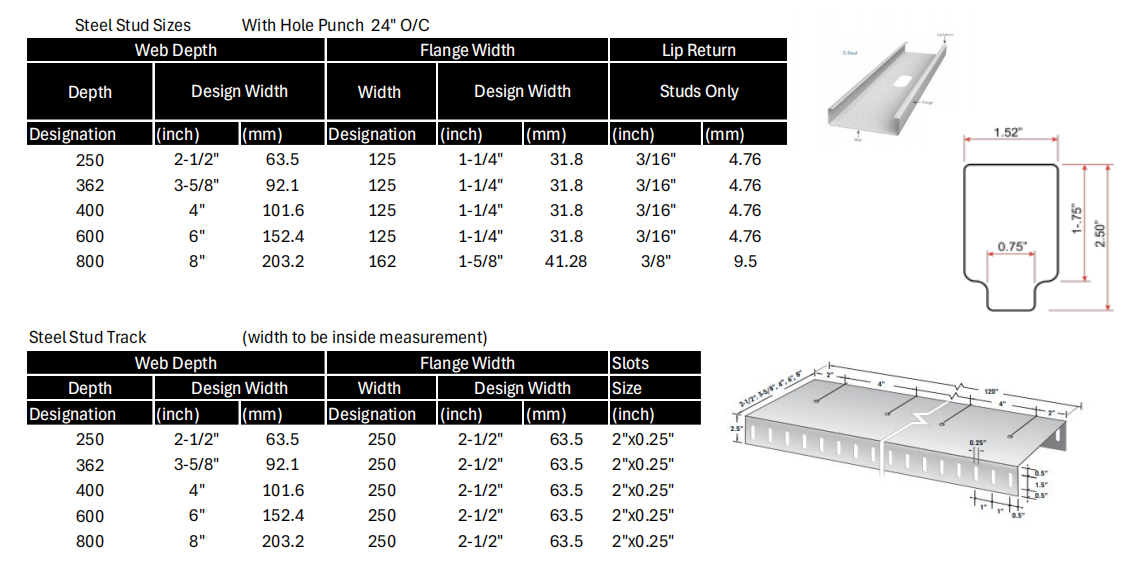

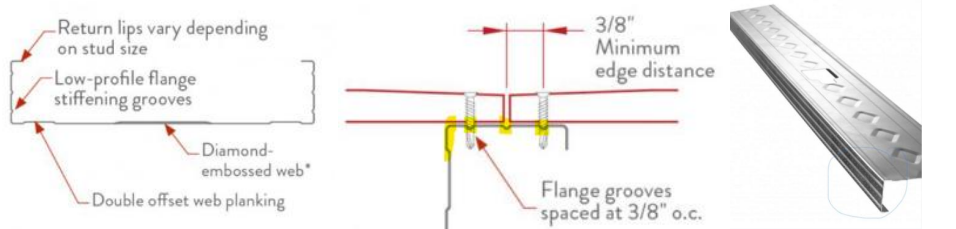

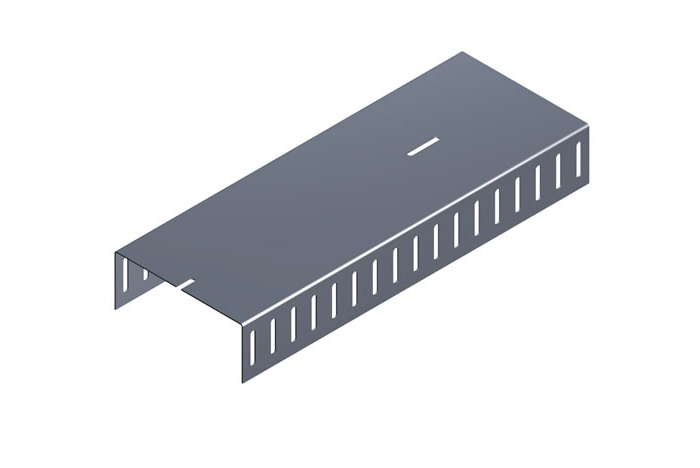

Here is one drawing profile and finished product:

Customer drawing profile:

Slot track &Stud and track:

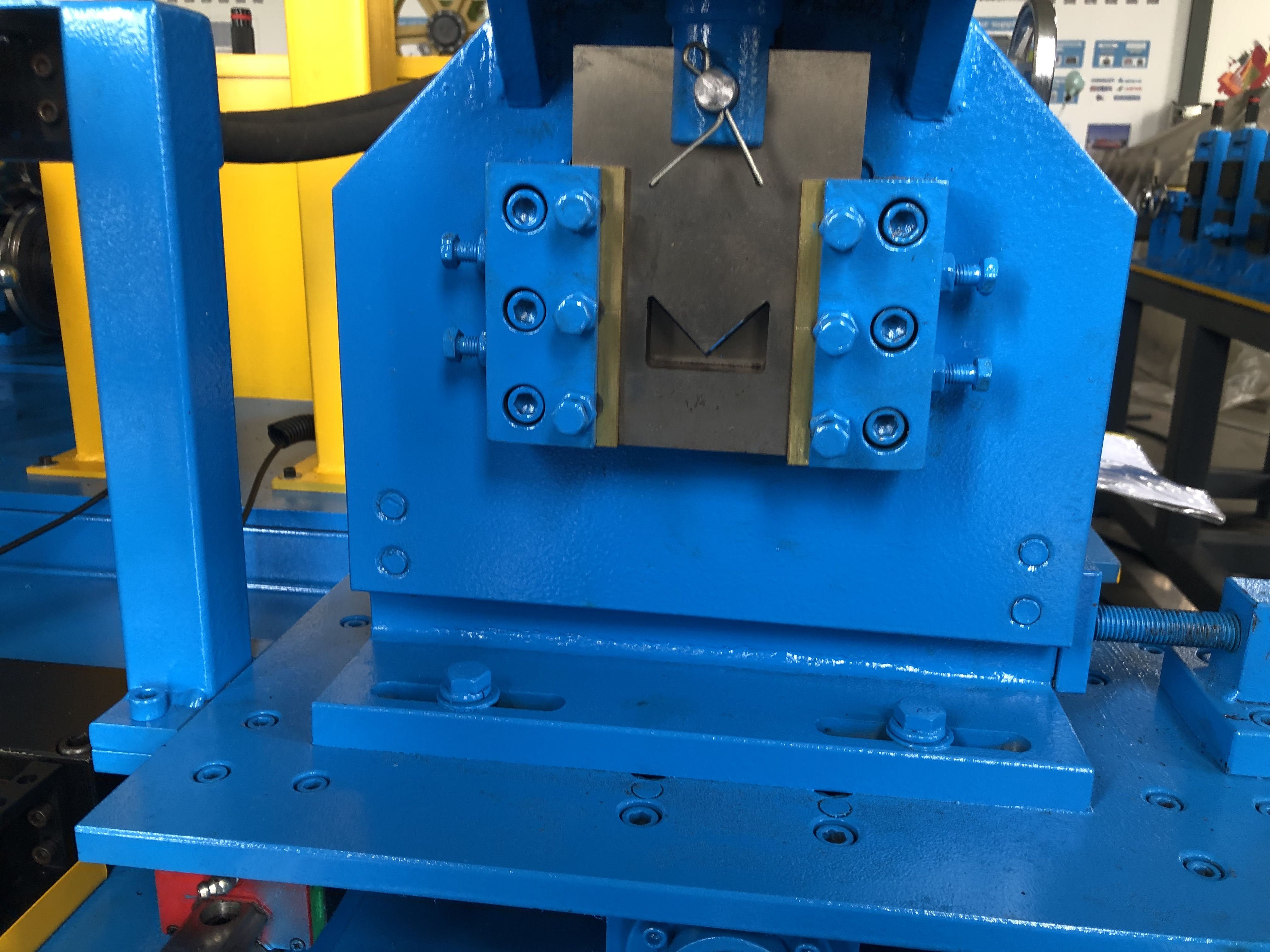

With the ribs making and dotting rollers

Description/Technical Parameter details of complete line:

1.2 Tons Hydraulic Un-coiler with pre-leveling device

2.Motorized driving coil rotation, auto stop/start control, 2.2KW

3.Load capacity=2Ton

4.Coil width: 200mm

5.Coil Inner-diameter: Φ510±30mm

6.Independent pre-leveling device:For heavy gauge material, Driven and level by motor

7.Professional Lubrication device:Equipped between the roller feeder and the press

8.Auto Feed in Device:Servo motor: YASKAWA, 1.8KW or as order

9.PresserCapacity: 80/110 tons or as per detailed requirement/Chinese Brand: YANGLI

10.Roll Forming machine:18 stages to form.

Rollers manufactured from Cr12, heat treatment

Shafts Diameter=ф75mm, Precision Machined

Main motor =11KW, Frequency speed control

Max. line speed of roll former:Approx. 12-15m/min

11.Hydraulic cutting device

Flying cut

After cut off, there are 8mm material waste

12.PLC Control System

Siemens brand PLC and touch screen, Schneider brand Inverter, Omron encoder

What is the slotted track?

A slotted track is a type of structural component used in construction, particularly in drywall partition systems and other framing applications. It is characterized by having slots or openings along its length, which provide various functional benefits, especially in scenarios requiring the accommodation of structural movement and stress.

Key Features of Stud and Track Steel

1.Typically made from galvanized steel for excellent corrosion resistance, ensuring longevity and durability in various environments.

2.Manufactured with precise dimensions to ensure a perfect fit and alignment in construction projects.

3. Available in various profiles, including C-studs, U-tracks, and other shapes to meet different structural requirements.

4.Despite their strength, these components are lightweight, making them easy to handle and install. Often come with pre-punched holes for electrical wiring and plumbing, simplifying the installation process.

5.Steel studs and tracks are non-combustible, providing added fire resistance to the structure.Enhances the overall safety of the building, especially in commercial and residential applications.

6.Can support significant loads, ensuring structural integrity for walls and ceilings.

7.Suitable for various architectural designs and layouts, offering flexibility in construction planning.

Applications of Stud and Track Steel

Drywall Partition Systems

Suspended Ceiling Systems

Load-Bearing Walls

Exterior Wall Framing

Material / Product Specification

Nonstructural (Drywall) Products:

18-30 mil: 33 ksi

25EQ: 50 ksi

20EQ, 30EQD: 57 ksi…………ASTM A1003/A653, C645

Structural Framing Products:

33-43 mil: 33ksi

33EQS, 43EQS: 57 ksi

54-127 mil: 50 ksi…………ASTM A1003/A653, C955

Coating Specification

Nonstructural (Drywall) Products:

25EQ, 20EQ, 30EQD, 18-30 mil: G40…………ASTM A1003/A653, C645

Structural Framing Products:

33EQS, 43EQS, 33-97 mil: G60…………ASTM A1003/A653, C955

Note: Contact ZTREM for heavier coating thickness availability.

Benefits