Over the years, with extensive experience in addressing practical production challenges for our customers, we have integrated the best aspects of similar products from both domestic and international markets. This has allowed us to continually enhance the design and performance of our Shelving Panel Making Machine, Billboard Panel Making Machine, and Grain Silo Making Machine. In the face of increasingly fierce market competition, our company has consistently remained competitive and resilient. Leveraging more professional technology and advanced, sophisticated equipment, we assist our company in establishing a stronger foundation for success. We continuously adapt to strategic and environmental changes, optimize our product portfolio, and strengthen our commitment to meeting customer needs. Our clients are primarily distributed across North America, Africa, and Eastern Europe.

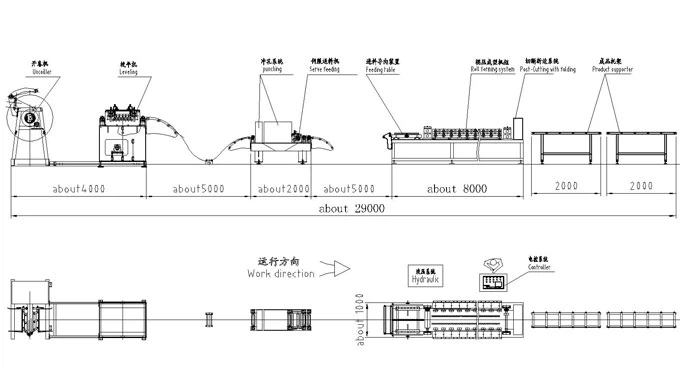

Our equipment is composed of the following components:

Active uncoiler

High-precision punch feeder

High-speed punching press (including die)

Precision cold rolling forming machine

CNC shear

Receiving rack

Metal Facade Roll Forming Machine

The Metal Facade Cladding is a modern building material used in facade designs. It serves as a screen wall cladding solution, prepared in accordance with building design parameters on steel or aluminum frames. Metal cassette cladding, developed for building facades, uses clamps to secure metal plates, effectively addressing future water insulation issues.

Tube Punching Machine

Storage shelves, typically composed of columns, beams, and shelves, require high-precision processing. Our Tube Punching Machine is specifically designed for manufacturing supermarket racks and shelves. It is ideal for processing the frames used in Supermarket Shelving, Department Stores, Pallet Rack Systems, and more.

Supermarket Shelf Panel Making Machine

Raw material thickness: 0.5-1 mm

Material: G350Mpa cold-rolled or hot-rolled steel, galvanized steel

Input material width: Customized based on specifications

Production line speed: 6-8 m/min

Working area: Approx. L15,000*W2,000 mm

The Supermarket Box Board Roll Forming Machine production line is equipped with the following components:

Hydraulic decoiler

Servo feeding device

Hydraulic punching machine with dies

Roll forming machine section

Output table

Hydraulic oil pump

Electrical control cabinet

Technical Data: Supermarket Shelf Panel Roll Forming Machine

The Shelf Panel Making Machine is capable of producing shelf panels according to customized measurements. Roll forming stands move along a linear guide to adjust the roller gap, allowing for the production of various panel sizes. This flexibility ensures the machine meets diverse production requirements effectively.

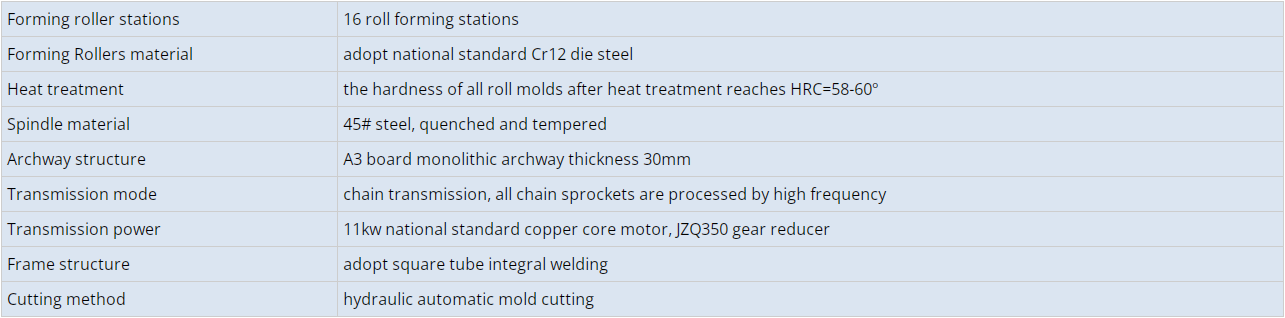

Technical Specification

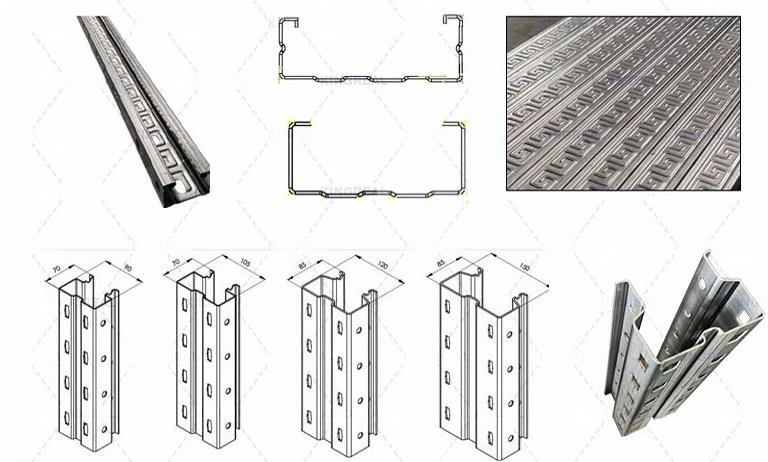

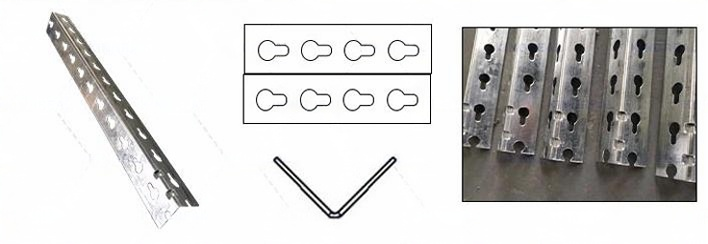

Product Application

Upright post

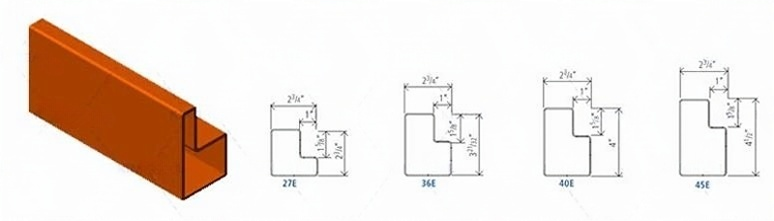

Thick angle profiles

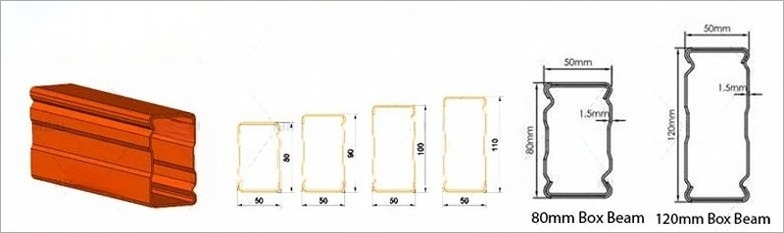

Box beam

Step beam