In modern steel structure buildings, purlins are essential secondary load-bearing components, especially in industrial plants, warehouses and other buildings. The choice of purlins plays a key role in the stability and load-bearing effect of the structure. At present, the commonly used purlin types are Z-type purlins and C-type purlins, which have obvious differences in appearance, performance and application scenarios. This article will analyze in detail the characteristics and differences of CZ-type purlins, as well as how to choose suitable purlins and cold-bending forming equipment in different building needs to meet the requirements of high-quality and high-efficiency construction.

The difference between Z-type purlins and C-type purlins

1.Cross-sectional structure and angle

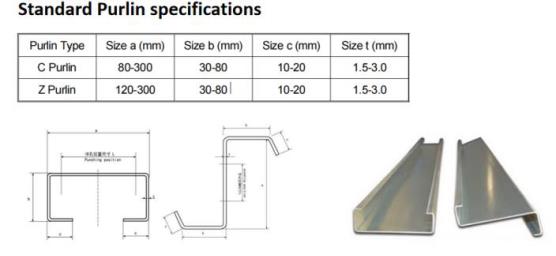

Z-type purlin: The cross-sectional angle of the Z-type purlin is less than 90 degrees, usually between 60 and 75 degrees, presenting a unique “Z” shape. This design has advantages on roofs with a certain slope, which can better bear the roof load and make the force more uniform.

C-type purlin: The cross section of the C-type purlin is a standard “C” shape with an angle of 90 degrees, which is suitable for installation in roofs or wall structures with a small slope. It has a simple structure, light weight, and is easy to construct and install.

2.Force performance

Z-type steel purlin: Due to its unique angle and shape, it has excellent bending resistance, especially suitable for building structures with large roof slopes and large loads. In continuous structures, Z-type purlins can be rigidly connected by overlapping, greatly improving the overall stability of the structure.

C-type steel purlin: The force difference between the strong and weak axes of the C-type purlin is large, and the bending resistance is slightly weaker than that of the Z-type purlin. It is suitable for roofs or wall support structures with a small slope, and mainly bears loads in the form of simply supported components.

3.Installation connection method

Z-shaped steel purlin: Z-shaped steel purlin can be reliably connected by staggered overlapping, which is suitable for continuous beam structures. The overlapping method gives it an advantage in the application of long spans and continuous components.

C-shaped steel purlin: C-shaped steel purlins are mostly hinged with bolts, and are easy to connect to the steel frame. They are suitable for occasions where they are subjected to force alone or simply supported.

How to choose the right type of purlin

For roofs with larger slopes: Z-type purlins are preferred. Z-type purlins can fully exert their bending resistance under larger slopes, so that the combined force of the roof load passes through the centroid of the purlin section, improving the load-bearing stability.

For roofs or walls with smaller slopes: It is more reasonable to choose C-type purlins. C-type purlins are light, easy to install and low in cost, and are suitable for small-span, low-slope roof and wall supports.

Continuous beam structure requirements: If purlins are required to form a continuous structure, the lap connection of Z-type purlins makes it perform better in long-span continuity and can effectively improve the stiffness of the building structure.

Selection of cold roll forming equipment

Choosing a suitable cold roll forming machine is the key to ensuring the quality of purlins, especially in a high-precision and high-efficiency production environment.

The following are several key points for selecting c&z purlin machines:

Selection of multi-function forming machines: Some cold roll forming machines can produce Z-type and C-type purlins at the same time, but the mold needs to be replaced. This type of equipment is suitable for producing purlins of various specifications. Although the initial cost is high, it is flexible and suitable for medium and large steel structure processing plants.

Precision and stability requirements: Precision cold roll forming machines can ensure the cross-sectional shape, surface finish and dimensional accuracy of purlins, and reduce production deviations. For large roofing projects, it is recommended to choose high-precision and high-wear-resistant equipment to ensure the stability of molding quality.

Automation level: Modern high-end cold roll forming machines are usually equipped with PLC control systems and automatic mold changing functions, which can realize batch and automated production and improve production efficiency. Especially in production scenarios where purlins of different specifications need to be frequently switched, automated equipment can reduce adjustment time and labor costs.

Material and strength compatibility: The cold-formed forming machine should support steel plates of various materials, such as Q195 to Q345, to meet different strength requirements and adapt to a wide range of building use scenarios.

Summary

In steel structure buildings, it is crucial to choose the right purlin type and forming equipment. Z-type purlins perform well in roofs with large slopes and continuous beam structures, and are suitable for bearing large loads; while C-type purlins are more suitable for roofs with small slopes and wall supports, and are easy to install and cost-effective. When purchasing cold-formed forming equipment, the accuracy, automation level and compatible material strength of the equipment should be considered to ensure the production quality and construction efficiency of the purlins.

Reasonable purlin selection and equipment investment can not only improve the stability of the steel structure, but also save subsequent construction and maintenance costs, providing strong guarantees for the safety and durability of steel structure buildings.