Roof seaming machines are indispensable tools in the construction and roofing industries, particularly when working with metal roofing systems. These machines play a crucial role in ensuring that metal panels are securely joined together, creating durable, watertight seams that protect the roof from weather elements. In this comprehensive guide, we will explore what roof seaming machines are, the different types available, their benefits, and tips for proper maintenance to ensure optimal performance.

What is a Roof Seaming Machine?

A roof seaming machine is a specialized tool designed to join metal roofing panels by folding and pressing their edges together to form strong, weather-resistant seams. These machines are used in both commercial and residential roofing projects to ensure the longevity, durability, and structural integrity of metal roofs.

Seams are the points where metal panels overlap, and a proper seam is critical for preventing water infiltration, wind damage, and other potential failures. A roof seaming machine automates the process of creating these seams, making the job more efficient, consistent, and reliable. The machine is especially useful for standing seam metal roofing systems, which require tightly locked seams to provide waterproofing and support thermal expansion.

Types of Roof Seaming Machines

There are various types of roof seaming machines, each designed for specific project sizes, material types, and performance requirements. Below are the most common categories:

1. Manual Roof Seaming Machines

Manual roof seaming machines are operated by hand and are commonly used for small to medium-sized roofing projects. These machines are portable, easy to use, and do not require electricity, making them an excellent option for remote or off-grid locations. However, manual seaming can be labor-intensive and slower than other types of machines, requiring more effort and time to complete larger projects.

2. Electric Roof Seaming Machines

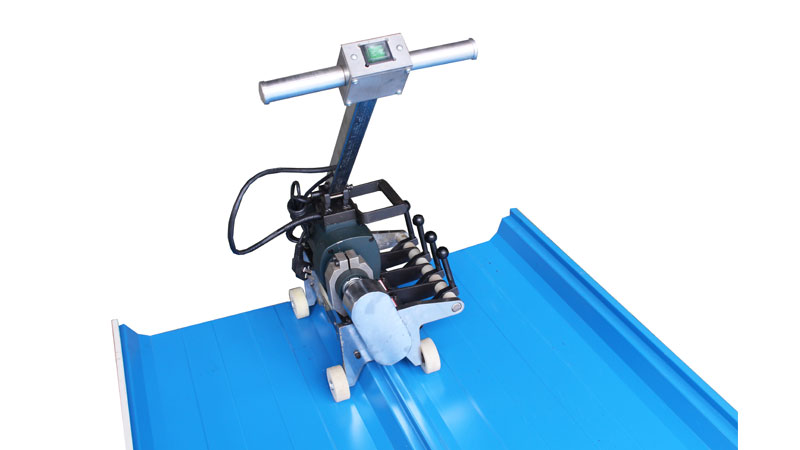

Electric roof seaming machines are powered by electricity and offer significantly more efficiency and precision compared to manual machines. These machines are commonly used in larger roofing projects and can handle thicker and more durable metal panels, such as steel and aluminum. Electric seaming machines speed up the seaming process and reduce the physical strain on workers, making them an attractive option for professional roofers.

3. Hydraulic Roof Seaming Machines

Hydraulic roof seaming machines are the most powerful and efficient of the three types, using hydraulic pressure to create strong, uniform seams. These machines are designed for large-scale commercial roofing jobs and can handle the heaviest and thickest metal panels. Hydraulic machines deliver consistent and high-quality results, even on the most demanding roofing projects. They are more complex and require regular maintenance, but their performance makes them a top choice for professional roofers working on big installations.

Installation: Machines for Seaming Tite-Loc Panels

Once Tite-Loc panels are manufactured, they must be installed and securely seamed to ensure their performance as a roofing system. The process of seaming involves using specialized machinery that locks the panel seams together, creating a watertight seal.

1. Mechanical Seaming Machines

Tite-Loc panels require mechanical seaming machines to lock the panel seams after they are installed on the roof. These seamers fold the edges of the panels into place, forming either a 90-degree lock (for standard Tite-Loc panels) or a 180-degree lock (for Tite-Loc Plus panels). The seaming process is essential to prevent leaks and ensure that the roof withstands harsh weather conditions, such as wind, rain, and snow.

D.I. Roof Seamers is the approved supplier of mechanical seamers for Tite-Loc panels, ensuring that the tools used for the seaming process meet the manufacturer’s specifications. Their seamers offer:

- Precision: Seaming machines are designed to apply consistent pressure, ensuring uniform seams that maintain the roof’s integrity over time.

- Efficiency: Electric and hydraulic seamers are faster than manual tools, making them ideal for larger roofing projects where time is a factor.

2. Hand Crimpers

In addition to mechanical seamers, hand crimpers may be used for smaller or more intricate areas of the roof that the larger machine cannot reach. Hand crimpers are particularly useful for finishing tight corners, edges, or other challenging spots.