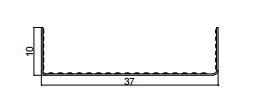

Omega Light Steel Keel

- Description:

Omega-shaped light steel keel is typically used for ceiling construction.- Standard Dimensions: 20mm x 30mm or 20mm x 40mm.

- Thickness Range: 0.4mm to 1.0mm.

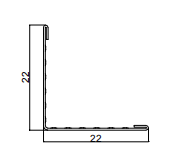

L-Shaped Light Steel Keel

- Description:

L-shaped light steel keel is commonly used for edging and corner structures.- Standard Dimensions: 25mm x 25mm and 15mm x 15mm.

- Thickness Range: 0.4mm to 0.6mm.

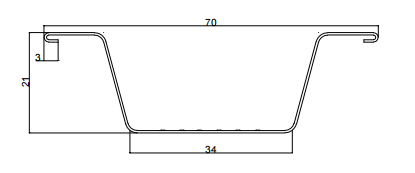

U-Shaped Light Steel Keel

- Description:

U-shaped light steel keel is usually used as vertical support in ceilings or walls.- Standard Dimensions: 50mm x 40mm.

- Thickness Range: 0.4mm to 1.0mm.

Specific dimensions may vary based on customer requirements, local standards, and regional differences. The above information can serve as a reference.

Shift from Wooden Keels to Light Steel Keels

As many international customers prioritize efficiency and ease of transportation in building construction, the industry is witnessing a significant shift from wooden keels to light steel keels.

Comparison of Light Steel Keels and Wooden Keels (Based on Domestic Market Trends)

- Material:

- Light steel keels are made of steel plates, whereas wooden keels are made of timber.

- Weight:

- Light steel keels are lighter, making them easier to transport and install compared to wooden keels.

- Strength:

- Light steel keels are stronger, more durable, and resistant to moisture, rot, and deformation.

- Precision:

- Light steel keels offer high manufacturing precision, while wooden keels are influenced by the quality of the timber and are less consistent.

- Usage:

- Light steel keels are suitable for indoor and outdoor wall and ceiling installations, whereas wooden keels are primarily used indoors for wall-mounted structures, wooden floors, ceilings, and furniture.

In summary, the choice between light steel and wooden keels depends on the specific application and requirements of the project.

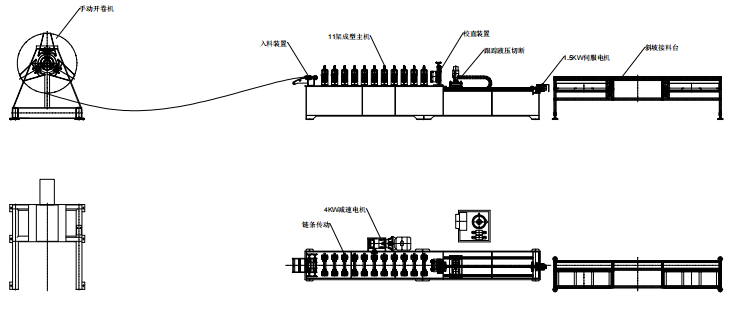

Machine Configuration Suggestions

New operators can select machine configurations based on project-specific needs.

Machine Structure

- Options:

- Cast Iron Gantry: Thickness of 20mm.

- Types:

- Line-cut gantry (higher cost).

- Standard cast iron gantry (lower cost).

- Operators should carefully identify the type required.

- Types:

- Cast Iron Gantry: Thickness of 20mm.

Transmission Methods

- Types:

- Chain Drive: Requires gantry structures on both sides.

- Gear Drive: Features a gantry on one side and an integral middle plate on the other (lower cost).

Roller Material

- Commonly made of GCr12 steel for durability and precision.

Punching Stations

- A single punching station costs approximately 5,000 RMB. The price may vary depending on the product design and required sizes.

Cutting Methods

- Options:

- Tracking Cutting:

- Recommended for its higher speed (35–45 meters per minute).

- Stop-and-Go Cutting:

- Suitable for smaller-scale production but less efficient.

- Tracking Cutting:

This information provides a comprehensive guide for selecting light steel keel machines and their configurations based on project requirements.