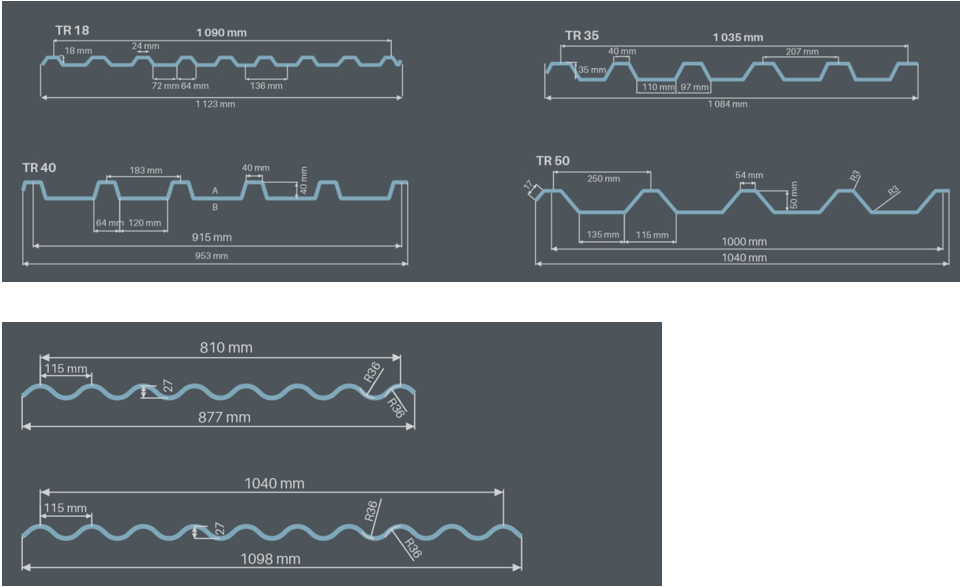

Double-layer roof panel forming machines can flexibly switch between upper and lower molds, and are suitable for producing roof panels of various specifications. The following are several common board types suitable for double-layer roof panel forming machines:

Trapezoidal Panel

Corrugated Panel

Standing Seam Panel

Glazed Tile Profile

Flat Sheet

Clip Lock Panel

Double layer tile pressing equipment is equipped with a clutch device,with this device,the upper and lower layers of the machine will not work at the same time,which can reduce the wear of the drum,and the life of the machine will be longer.

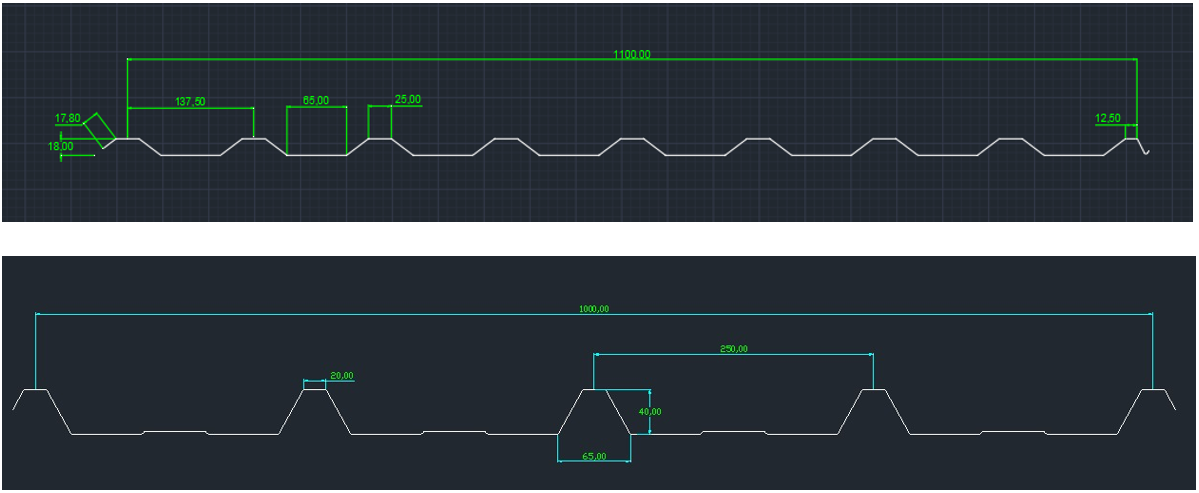

Below is a version of the Slovenian customers:

Thickness:0.4-0.7 mm

Feed width:1250 mm

Below is the local popular version diagram:

Double Layer Roofing Sheet Machine For The Republic Of Slovenia

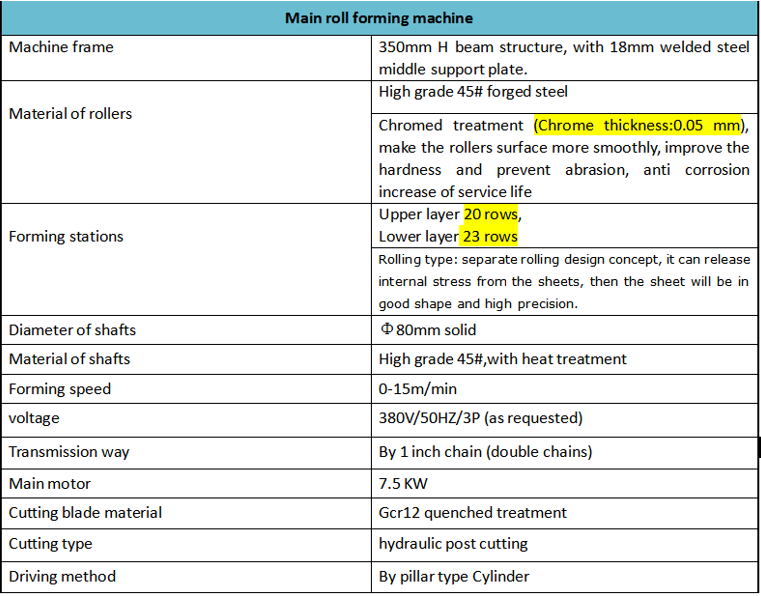

Main features of double-layer roofing sheet machine

Multifunctional design: The double-layer roofing sheet machine can produce two different types of roofing panels on the upper and lower layers, and can quickly switch panel types without changing molds.

Automated control: Equipped with a PLC control system, which can accurately control the length, thickness and width of the plate. Operators can adjust parameters on the control panel to easily realize automated production.

High efficiency: Compared with single-layer molding machines, the double-layer design can significantly improve production efficiency. One machine can complete the production of two different plate types, reducing machine change time.

Space saving: The double-layer design effectively saves factory space and is very suitable for production workshops that require a variety of panels.

Main parameters of Double Layer Roofing Sheet Machine For The Republic Of Slovenia

6T Hydraulic Decoiler with a track

Four circular arc arms are very steady and will keep the coil in shape compared to the square tube arm.

There is a groove in the battle, so that when the steel coil is hoisted by a sling, it can be conveniently accessed.

Dovetail groove type diameter adjustment mode of the decoiler is more stable and has better bearing capacity.

The significance of the track is that multiple machines can share a hydraulic rolling machine.

Problems to pay attention to: due to the track, the car and the coder share the same frame, which means that the car is closer to the shaft of the coil in the height, so we must verify the specifications of the customer’s steel coil.

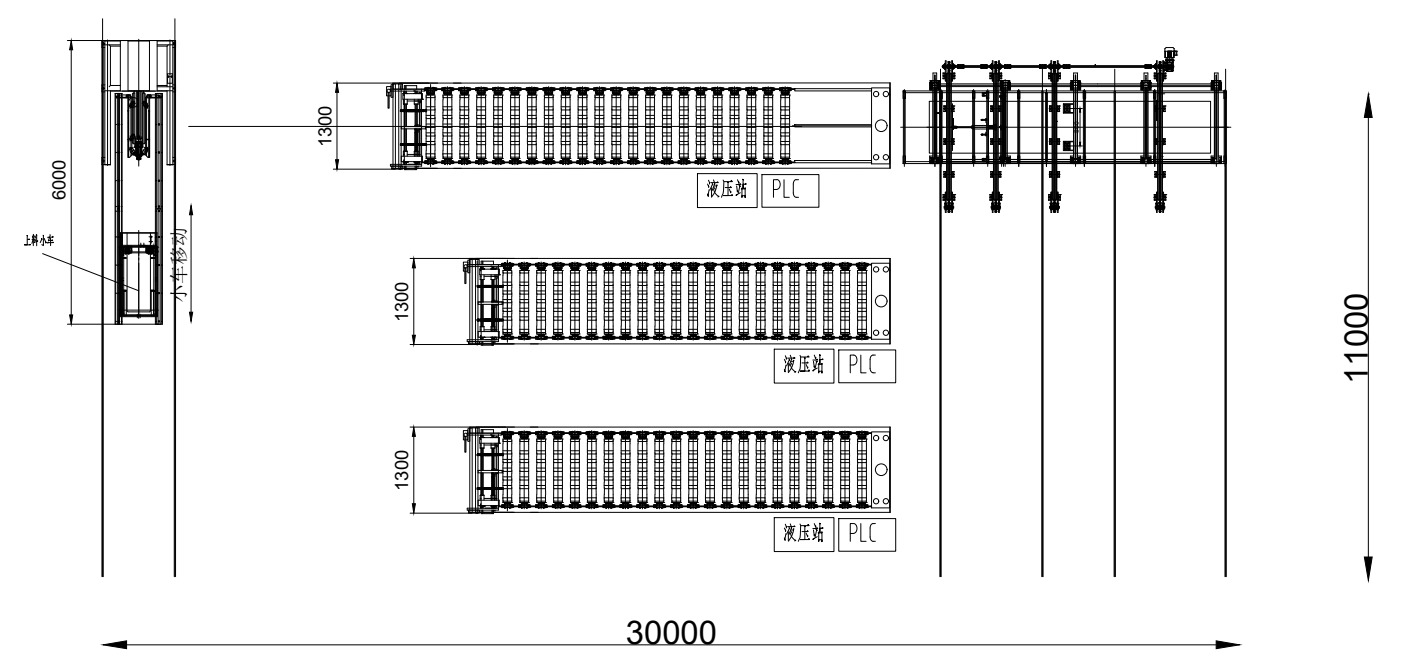

9M Automatic stacker with a track

This is a liftable automatic stacker with double layer roofing sheet machine. It is convenient to adapt to two discharge outlets with different heights, so as to receive two roofing sheet with different heights.

The meaning of a track is that multiple machines can share a palletizing.

Need to pay attention to: the height of the ground to the machine exit, the minimum height. The height of the double-layer palletizing stack is adjustable.

Schematic of hydraulic decoiler with a track and automatic stacker with a track

Lift the car

Too high falling airflow, the code is not uniform, can be used lifting car

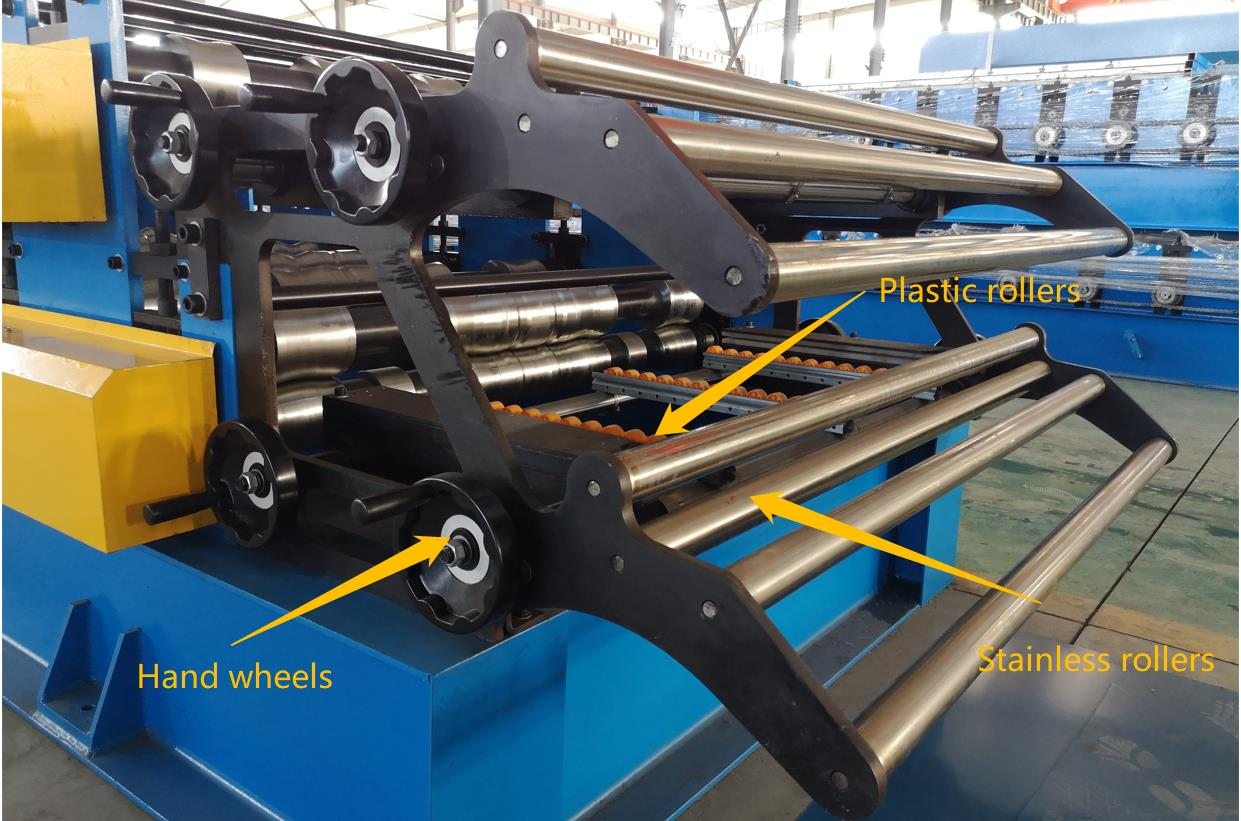

Guide Feeding Device

We design three supports and one pressure, and the rollers can be rotated, which can reduce the friction between the steel and the rollers. The top roller also prevents the steel from sticking up.

Each layer has two rows of rubber rollers, which also avoid material scratches.

The side has chain links and nylon brackets, which protect the steel from scratches. The upper nylon plate has a partial missing to observe the position of the steel when feeding.

Insert screws also prevent scratches to the steel. The hand wheel on the side can be used to adjust the feed width for precise feeding.