The production of R-Panel metal roofs requires a dedicated R-Panel Roll Forming Machine. This machine can efficiently process metal materials to form roof panels that meet R-Panel specifications and is widely used in industrial, commercial and residential buildings.

Key Features of R Plate Roll Forming Machine

Material Compatibility

A wide range of materials can be processed, such as galvanized steel, color-coated steel (PPGI) and aluminum plates.

Usually applicable thickness range: 0.3mm – 0.8mm.

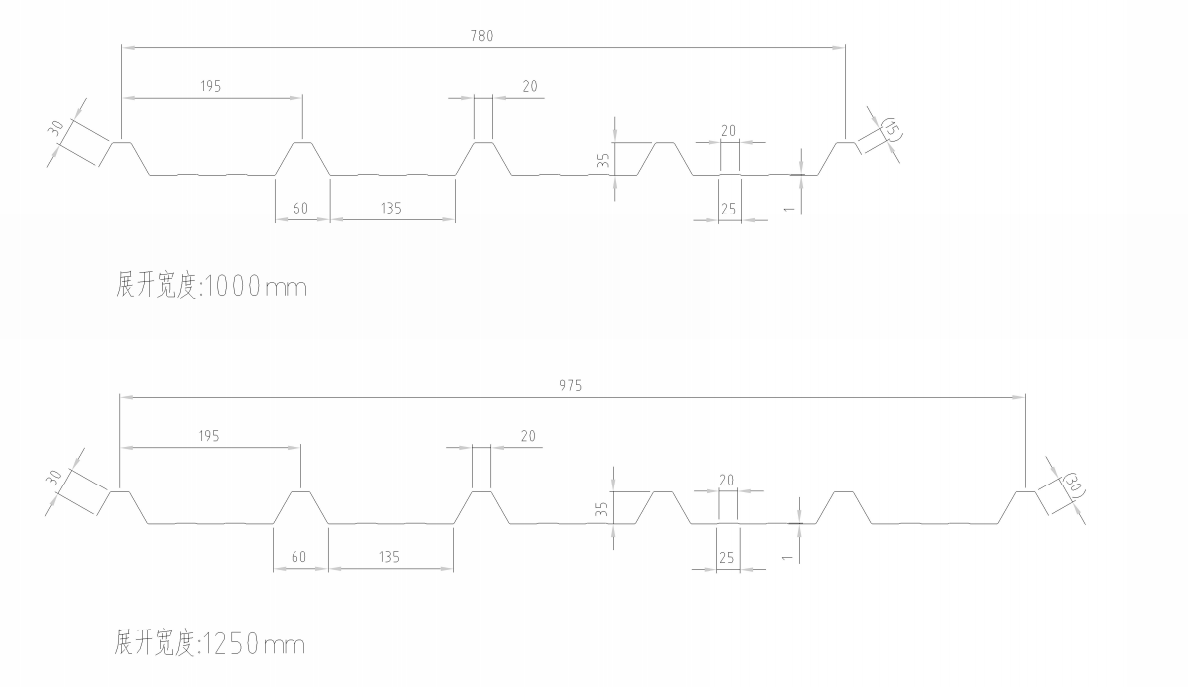

Forming Size

Standard R Plate Width: 26 inches or 36 inches (after forming).

Forming width can be customized to meet different market needs.

Automation Control

Equipped with PLC control system to achieve precise forming and automatic cutting, reduce manual intervention and improve efficiency.

Efficient Production

Production Speed: 10-20 meters/minute (adjustable according to machine specifications).

Suitable for large-scale continuous production.

Main components of the machine

Unwinding rack

Automatic or manual unwinding, used for feeding preparation of metal coils.

Forming host

Equipped with high-precision rollers and molds to ensure that the texture and waveform of the R plate meet the standards.

Cutting device

Hydraulic or servo cutting device, supports fixed-length cutting with high precision.

Control system

PLC (Programmable Logic Controller) realizes intelligent operation and supports switching of multiple specifications.

Discharging table

The R plate conveying and collection device after forming is convenient for subsequent packaging.

Recommended machine types for producing R-sheet metal roofs

Single-layer R-sheet forming machine

A machine that only produces one specification of R-sheet, with high cost performance and suitable for a single product line.

Double-layer forming machine

Produces R-sheet and other metal roof panels (such as U-sheet or corrugated sheet) at the same time, saving space and cost.

Multi-function forming machine

Can produce a variety of metal roof panels by changing the mold, suitable for manufacturers who need flexibility and diversified production.

What is R-Panel metal roof?

R-Panel is a versatile wall and roof panel used extensively in prefabricated metal buildings and is a popular choice for residential metal roofs, especially in the southwestern United States. R-Panel offers outstanding durability and economy, and its optional purlin brace legs (PBR) increase the support of the overlap and ensure a more stable fixed panel overlap. For added weather resistance, R-Panel comes standard with Kynar 500 (PVDF) coating, which has excellent resistance to fading and chalking, and can maintain its bright color and beautiful appearance for a long time.

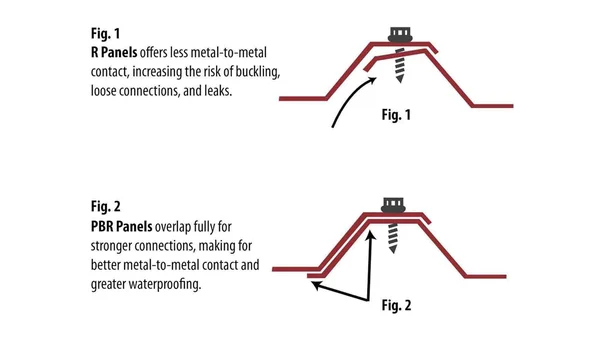

R-Panel vs. PBR-Panel

PBR panels and R-Panel are similar in size and profile, both with 36-inch coverage, but PBR panels are stronger due to the design of the purlin legs:

Weatherproof performance: PBR panels overlap more tightly, effectively preventing moisture, and are suitable for roofs with high waterproofing requirements.

Load-bearing capacity: PBR panels are stronger and less likely to be deformed by foot traffic during construction or maintenance.

Cost comparison: Although PBR panels are superior, their cost is only 2% to 3% higher.

R-Panel is more suitable for wall or metal siding applications, while PBR panels are more ideal for roof projects.

Whether you have any questions about the machine or the template, you can send us a message. In addition, our company also provides corresponding supporting machines, such as Gutter Forming Machine, downspout machine, ridge tile machine.

Summary: Economical and practical metal roof solution

R-Panel is an ideal alternative to traditional roofing materials with its low maintenance, 35-40 years of limited paint warranty, and a variety of color and texture options.